71

70

EN

EN

d) Pull on the work tool to check that it is

secured in the clamping mechanism. (note: it

is possible to pull the work tool in and out of

the clamping head by approx. 1.5 cm for the

purpose of enabling impact drilling/chipping).

Note:

y

It is natural that the clamped work tool has slight give

in its motion around its own axis.

To clamp in a drill with a smaller drilling diameter, it

is possible to insert a standard chuck head used on

drills equipped with an SDS plus shank or also a bit

carrier (not included) into the SDS clamping head of

the hammer drill, see fig. 5.

•

ATTENTION

y

When using chuck heads with an SDS clamping

shank or a bit carrier for screwing or unscrewing

threaded connections, the impact drilling mode

must not be used since the strong percussion of

the hammer drill would damage it.

•

ATTENTION

y

When performing chipping or drilling work in a raised

vertical position - for example when drilling into

ceilings, it is necessary to ensure that the falling debris

does not enter into the tool clamping system or the

motor vents, e.g. by putting on a cut tennis ball in front

of the clamping head or a protection of a similar type

(fig. 6A or 6B).

ROTATING THE CHISEL TO THE REQUIRED

POSITION - VARIO LOCK FUNCTION

y

Due to the shape of the used chisel tool and the requi-

red shape of the chiselled groove, it may be necessary

to rotate the chisel tool to a certain position, which is

enabled by the Vario-Lock system.

1. Slide the chisel tool into the SDS clamping head

of the hammer drill and secure it in place using

the above described method.

2. Turn the work mode selector dial to the positi

-

on with the „Vario-Lock“ symbol (see table 4).

3. Turn the chisel tool around its axis to the requi

-

red position for the chisel tool.

4. Then use the work mode selector dial to select

the chiselling mode (symbol in table 4) and this

will secure the chisel tool in the set position.

•

ATTENTION

y

The Vario-Lock function is intended only for

changing the orientation of the chisel tool and it

is not a work mode.

REMOVING THE WORK TOOL

FROM THE SDS CLAMPING HEAD

y

Push down the SDS clamping head and take out the inserted

work tool from the head. Then release the clamping head.

SETTING THE ROTATION DIRECTION

AND PROTECTION AGAINST ACCIDENTALLY

STARTING THE POWER TOOL

y

Fully push down the rotation direction toggle switch

(fig. 1, position 5) to set the required rotation direction

of the work tool.

y

For protection against accidentally starting the power tool, set

the rotation direction toggle switch to the middle position, this

will block the trigger switch to protect it against being acci-

dentally pulled. Do this whenever not using the hammer drill.

INSERTING THE BATTERY

y

Slide the battery into the respective location in the

hammer drill (fig. 1, position 7) so that it locks into

position with an audible click.

VI. Starting/speed

control/stopping

•

ATTENTION

y

Prior to starting the hammer drill, always check

that it shows no signs of damage or wear and

tear, and that all the installed components are

properly attached and secured in place.

STARTING

y

Start the power tool by pressing the trigger

switch (fig. 1, position 4).

y

The degree to which the trigger switch is pulled

enables fine, gradual control of the rotation

speed a/or impacts.

STOPPING

y

To stop it, release the trigger switch.

•

WARNING

y

Never change the work mode settings while

the hammer drill is running! This would result

in its damage. The work mode can only be chan

-

ged when the clamping head is not rotating.

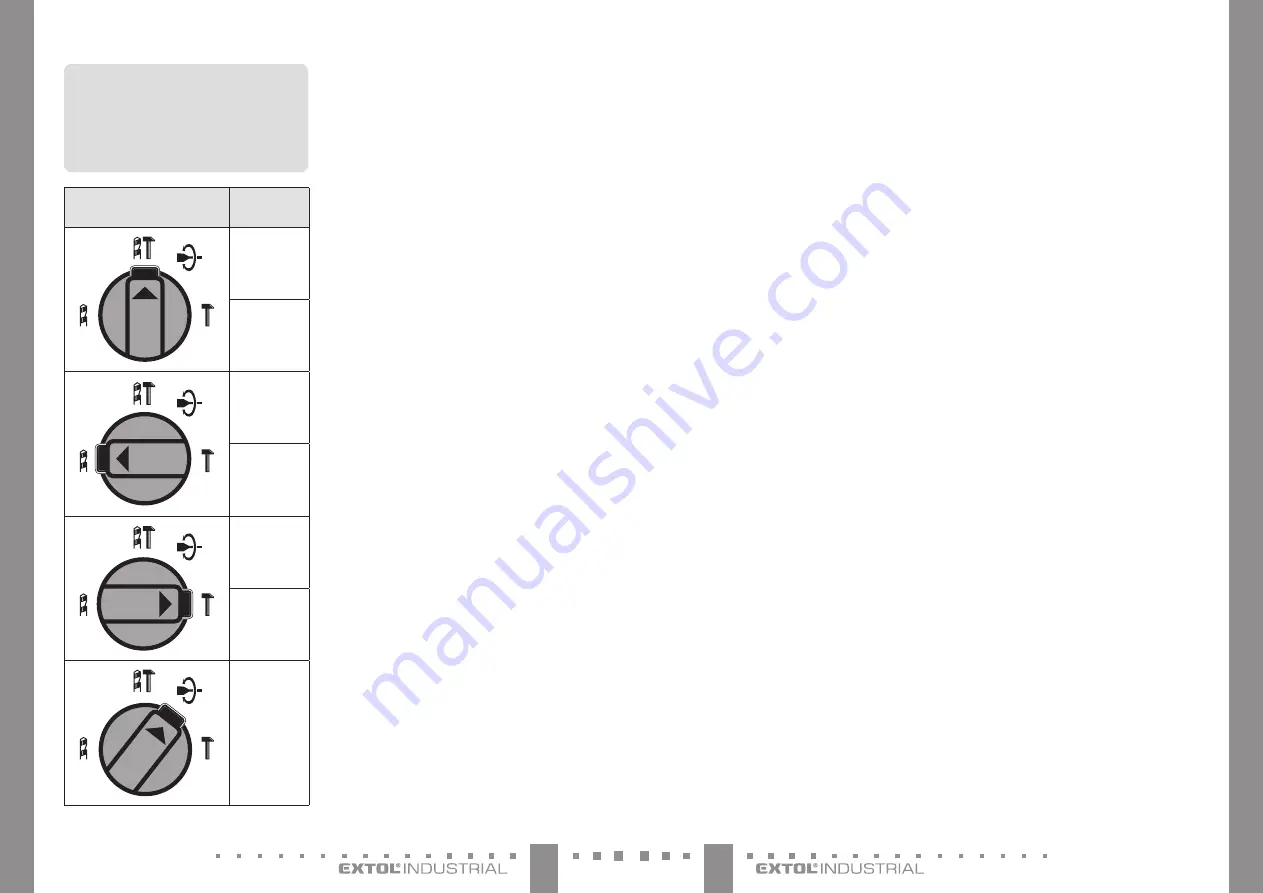

Setting the selector dial

for the respective work mode

Work mode:

Impact

drilling

For material:

Masonry

Concrete

Bricks

Work mode:

Impactless

drilling

For material:

Wood

Metal

Plastic

Work mode:

Chiselling

For material:

Masonry

Concrete

Bricks

Function:

Adjusting the

chisel to

a different

position,

Vario-Lock

function

Table 4

INSERTING/REMOVING THE WORK TOOL.

1. Select the appropriate work tool for the given

work task.

The clamping system of the hammer drill is intended

for the universal SDS plus clamping shank from

various manufacturers on the market.

It is necessary to select the correct work tool for

the given type of performed activity since this

determines the result and effectiveness of work.

y

For example, for chipping away tiles, use the flat chi-

sel, for making holes, for removing grouting mate-

rial, for making grooves, etc. use the pointed chisel,

for making cable troughs use a hollow chisel, etc.

y

For drilling, the appropriate drill bit must be selec-

ted based on the drilled material. For drilling into

metals and hard plastics, use drill bits from high-

-speed steel (HSS).

The SDS plus tool clamping head is universal and it is

possible to mount chisels of other manufacturers into

these hammer drills.

2. Thoroughly clean the SDS shank of the tool, dry

it if necessary and lubricate sufficiently using

Vaseline.

y

A shank with a layer of building dust, stones, etc.

damages the SDS tool mount.

3. Check that the hole is not damaged and the area

of the hole around the tool shank to prevent

the

entry of construction dust and stones during drilling/

chipping into the SDS clamping system of the head,

otherwise the clamping system will be damaged.

4. Insert the work tool into the SDS clamping

head in the following way (fig. 5):

a) Pull down the SDS clamping head.

b) Apply pressure on to the work tool with an

SDS shank to partially push it into the hole

of the clamping head and turn it until the

work tool slides into the grooves of the SDS

clamping head, after which it will not be

possible to turn the work tool.

c) Release the SDS clamping head from the

pulled down position and subsequently

slide the tool down all the way.