Chapter 4 – Display Screens

User Manual

28

Vortex

®

Precedence

Rev 3.6

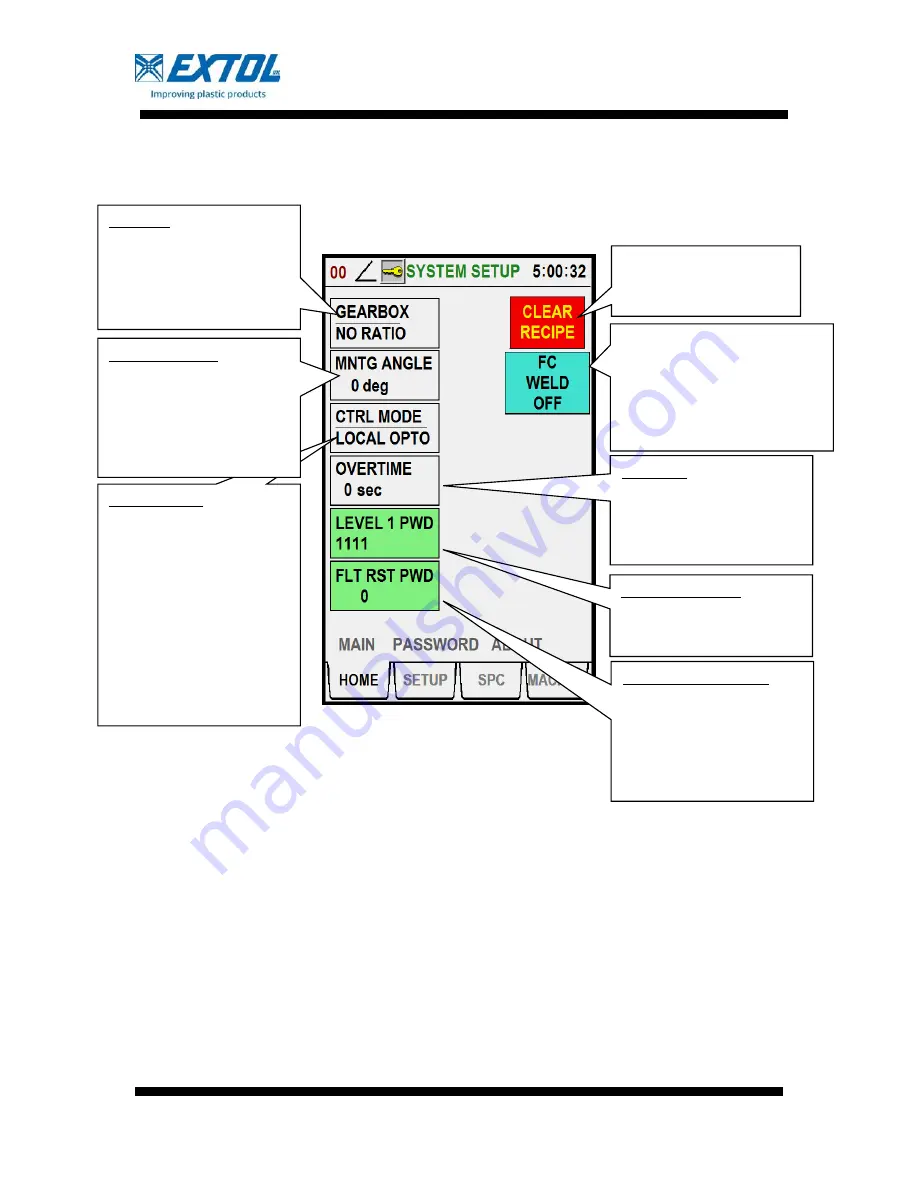

System Setup Screen

The System Setup Screen contains machine setup parameters.

Gearbox:

Select which gearbox is in

the machine.

1:1 – No gearbox

3:1

5:1

Control Mode:

Local Opto (standard):

Dual opto-touch start

buttons and DB-9

connector for tool IO.

Local LC (Light Curtain):

Light curtain, single opto-

touch start button and DB-

9 connector for tool IO.

Remote: Remote operation

for cell integration. No DB-

9 connector.

Clears the current recipe

and sets all parameters

to default values.

Level 1 Password:

Password that allows

editing of setup

parameters.

Fault Reset Password:

If the Alarm Mode is set to

“Latching” on the Pass/Fail

screen this password must

be entered to continue

machine operation after a

part fault.

Overtime:

Enter the maximum cycle

time allowed before a

cycle overtime fault is

generated.

Flow Control (FC) setting

during the weld. OFF allows

the machine to get to the

achieved force very quickly.

ON would slowly increase the

force to the desired.

Mounting Angle:

Select the machine

mounting angle so the

cylinder compensates

appropriately for spindle

weight. 90 deg is normal.

-90 deg is upside down.

Summary of Contents for VORTEX PRECEDENCE G1

Page 66: ...Chapter 6 Operation User Manual 60 Vortex Precedence Rev 3 6 Sequence of Operations Flowchart ...

Page 69: ...Chapter 6 Operation User Manual 63 Vortex Precedence Rev 3 6 ...

Page 88: ...Chapter 8 Troubleshooting User Manual 82 Vortex Precedence Rev 3 6 Servo Drive Alarms ...

Page 89: ...Chapter 8 Troubleshooting User Manual 83 Vortex Precedence Rev 3 6 ...

Page 90: ...Chapter 8 Troubleshooting User Manual 84 Vortex Precedence Rev 3 6 ...

Page 91: ...Chapter 8 Troubleshooting User Manual 85 Vortex Precedence Rev 3 6 Servo Drive Warnings ...

Page 104: ...651 Case Karsten Drive Zeeland MI 49464 1 800 324 6205 www extolinc com ...