Chapter 8 – Troubleshooting

User Manual

75

Vortex

®

Precedence

Rev 3.6

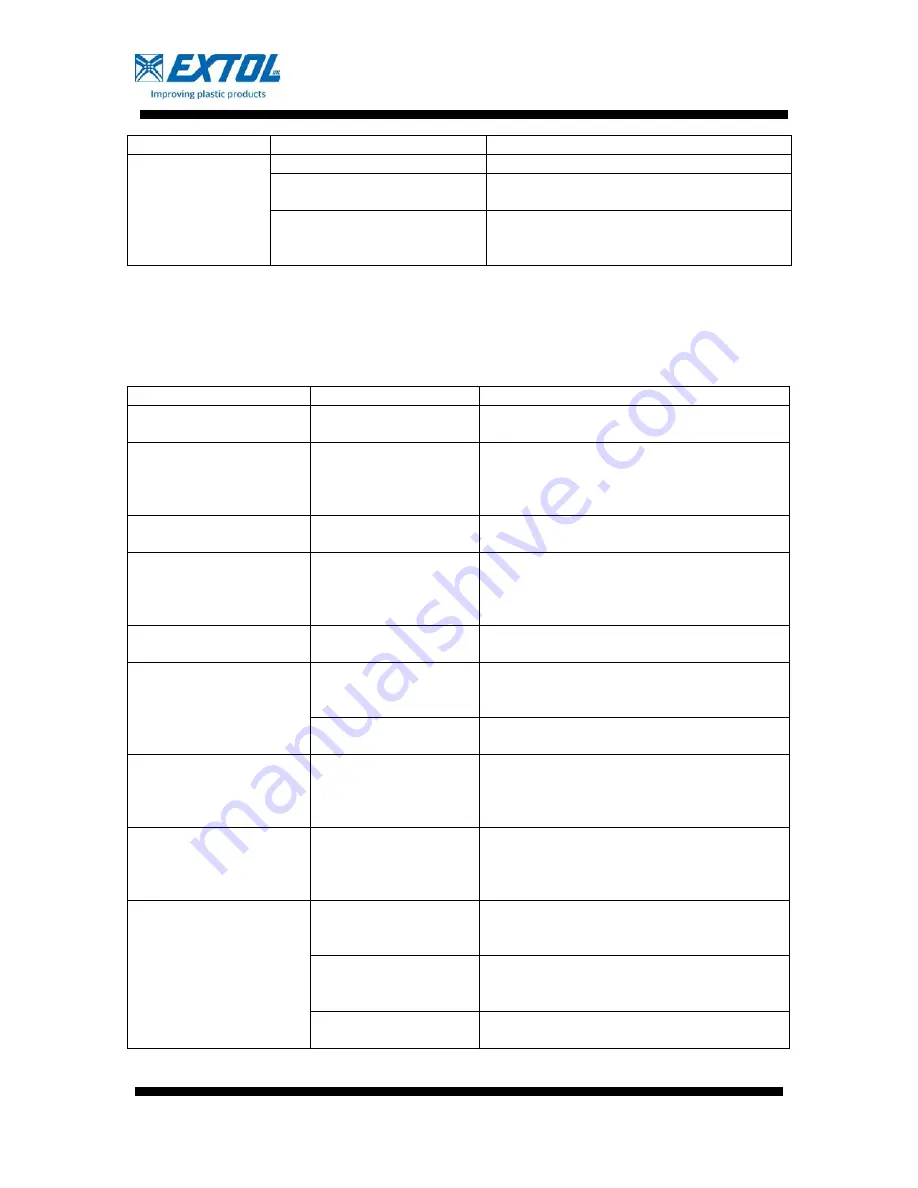

Issue

Cause

Resolution

Part is marked

after completion

Debris in upper or lower tool

Clean upper and lower tooling.

Part was presented to the

machine with damage

Check parts for marks before and after

processing.

Tool or details on tool may be

loose.

Check all fasteners and verify tightness.

Use blue loc-tite to retain fasteners that

come loose frequently.

Fault Messages

The following table lists possible fault messages, their cause and resolution.

In Remote Mode these faults will cause a Machine Fault output signal, except *.

Message

Cause

Resolution

EMERGENCY STOP! *

E-Stop button is

pressed.

Pull up E-Stop

AIR PRESSURE LOW

Electronic regulator is

unable to achieve

requested pressure

Check incoming air line for proper

connection.

Check setting on main regulator (85 psi

required).

RETRACT PRESS (PRESS

RESET)

Press is not fully

retracted

Press reset button on Main screen to retract

the press.

SERVO ALARM

Servo fault

Follow the message prompt and cycle

power to the machine to reset the fault.

If you are using the remote interface,

activate the servo reset input (Pin 8)

RESET SERVO (PRESS

RESET)

Servo is not at its start

angle.

Press the reset button to rotate the servo to

its start angle.

REMOTE SPC

COMMUNICATION

FAULT

Remote SPC box is not

connected to the

machine.

Check cables between the two devices. A

crossover cable is required if the devices

are connected directly (without a switch).

Ethernet address

settings are invalid.

Check the address settings on both the

machine and the Remote SPC box.

SAFETY TRIGGER WAS

NOT ACTIVATED *

The safety trigger was

not on when the head

reached its down

position.

Check the safety trigger adjustment. Refer

to Chapter 5.

START BUTTONS

RELEASED TOO SOON *

The start buttons were

released while the

head was in its down

motion.

Press Reset to return the machine to the

start position and begin the cycle again.

PREWELD HEIGHT IS

OUTSIDE TRIGGER

WINDOW

The parts were loaded

improperly or parts are

defective.

Press Reset. Examine and reload parts and

begin cycle again.

Trigger position or

trigger window

settings are invalid

Perform part setup procedure to determine

the correct values.

Machine column

height was adjusted.

Perform part setup procedure to determine

new trigger position.

Summary of Contents for VORTEX PRECEDENCE G1

Page 66: ...Chapter 6 Operation User Manual 60 Vortex Precedence Rev 3 6 Sequence of Operations Flowchart ...

Page 69: ...Chapter 6 Operation User Manual 63 Vortex Precedence Rev 3 6 ...

Page 88: ...Chapter 8 Troubleshooting User Manual 82 Vortex Precedence Rev 3 6 Servo Drive Alarms ...

Page 89: ...Chapter 8 Troubleshooting User Manual 83 Vortex Precedence Rev 3 6 ...

Page 90: ...Chapter 8 Troubleshooting User Manual 84 Vortex Precedence Rev 3 6 ...

Page 91: ...Chapter 8 Troubleshooting User Manual 85 Vortex Precedence Rev 3 6 Servo Drive Warnings ...

Page 104: ...651 Case Karsten Drive Zeeland MI 49464 1 800 324 6205 www extolinc com ...