3

1.

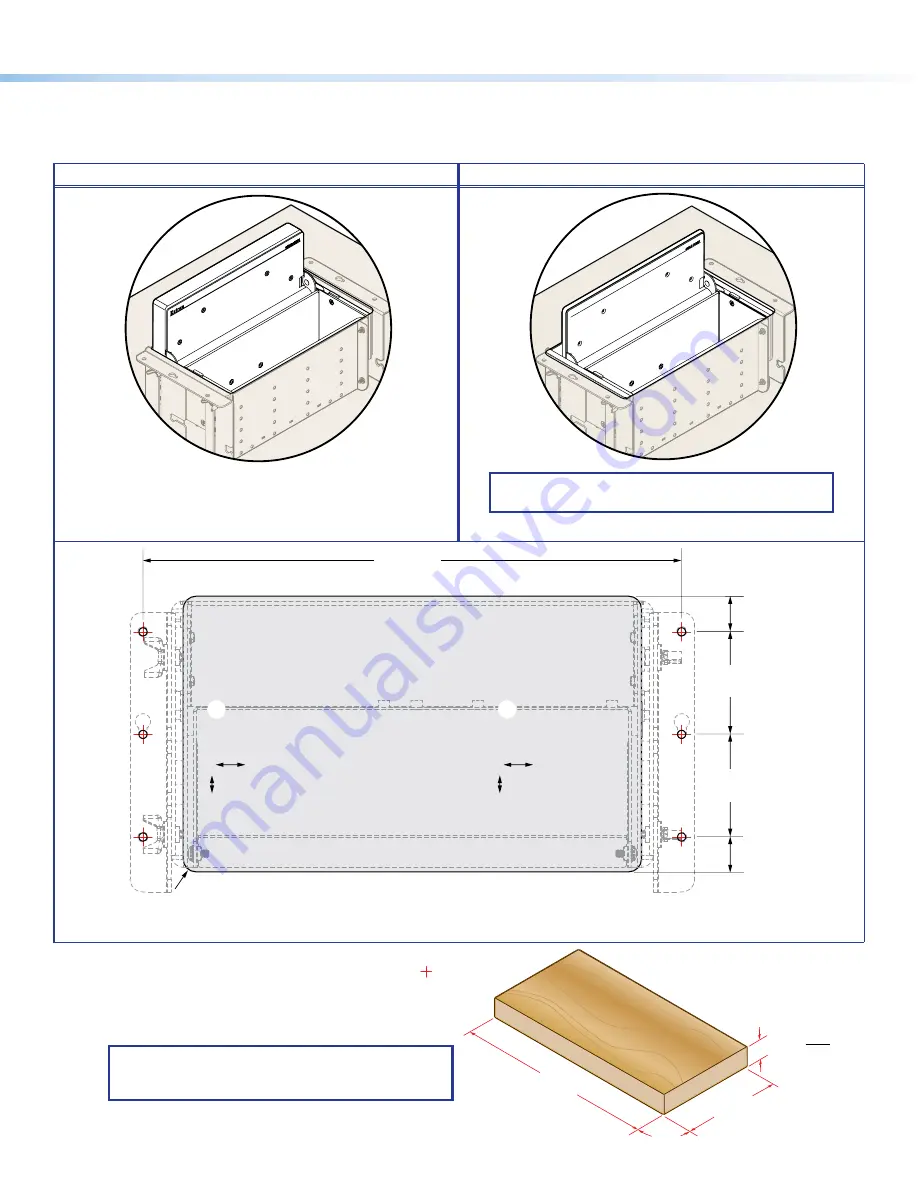

Cut a hole in the table for the Cable Cubby 1252 MS. See the table below to determine:

•

The location and orientation of the cut on the table

•

The correct size of the cut, based on the thickness of the table surface and the lid.

A

Lid is thicker than or as thick as the table surface

B

Lid thickness is thinner than table surface

Extr

on

Extr

on

Extr

on

NOTE:

A thinner lid requires a slightly larger cut

because the enclosure extends into the cut-out.

Figure 1.

Thicker Lid Material

Figure 2.

Thinner Lid Material

SURFACE

CUT-OUT

AREA

Bottom View

Front (Width)

Rear (Width)

2.00"

(50.8 mm)

2.00"

(50.8 mm)

0.63"

(16.0 mm)

10.50"

(266.7 mm)

0.63"

(15.9 mm)

R= 0.25" (6.3 mm)

Cut Dimensions

Thicker table surface:

Width:

8.81 inches

(223.8 mm)

Depth:

5.25 inches

(133.3 mm)

Corner 0.25 inch

radius:

(6.3 mm)

Cut Dimensions

Thinner table surface:

Width:

9.5 inches

(241.3 mm)

Depth:

5.25 inches

(133.3 mm)

Corner 0.25 inch

radius:

(6.3 mm)

A

B

Figure 3.

Enclosure Dimensions and Mounting Hole Locations

2.

Mark and pre-drill pilot holes, 1/8-inch in diameter,

8.56"

(217.4 mm)

4.43"

0.81"

(112.5 mm)

MAX

(20.6 mm)

(

Varying thickness

)

0.2"

(5 mm) Radius Corners

1/2-inch deep at the six mounting locations shown ( ) in

figure 3.

3.

Fabricate the Cable Cubby lid to the dimensions shown

at right.

NOTE:

Make the cut as accurate as possible, the

cutout piece can be used for the lid to be attached

to the Cable Cubby.