4

Cable Cubby 1252 MS • Installation Guide (Continued)

Preparing the Cable Cubby

Step 1 — Assemble Connectivity Modules

Connectivity modules allow you to populate the Cable Cubby enclosure with a combination of AAP modules, cable pass-through,

or retractors. Follow the steps below to assemble the connectivity modules of your choice.

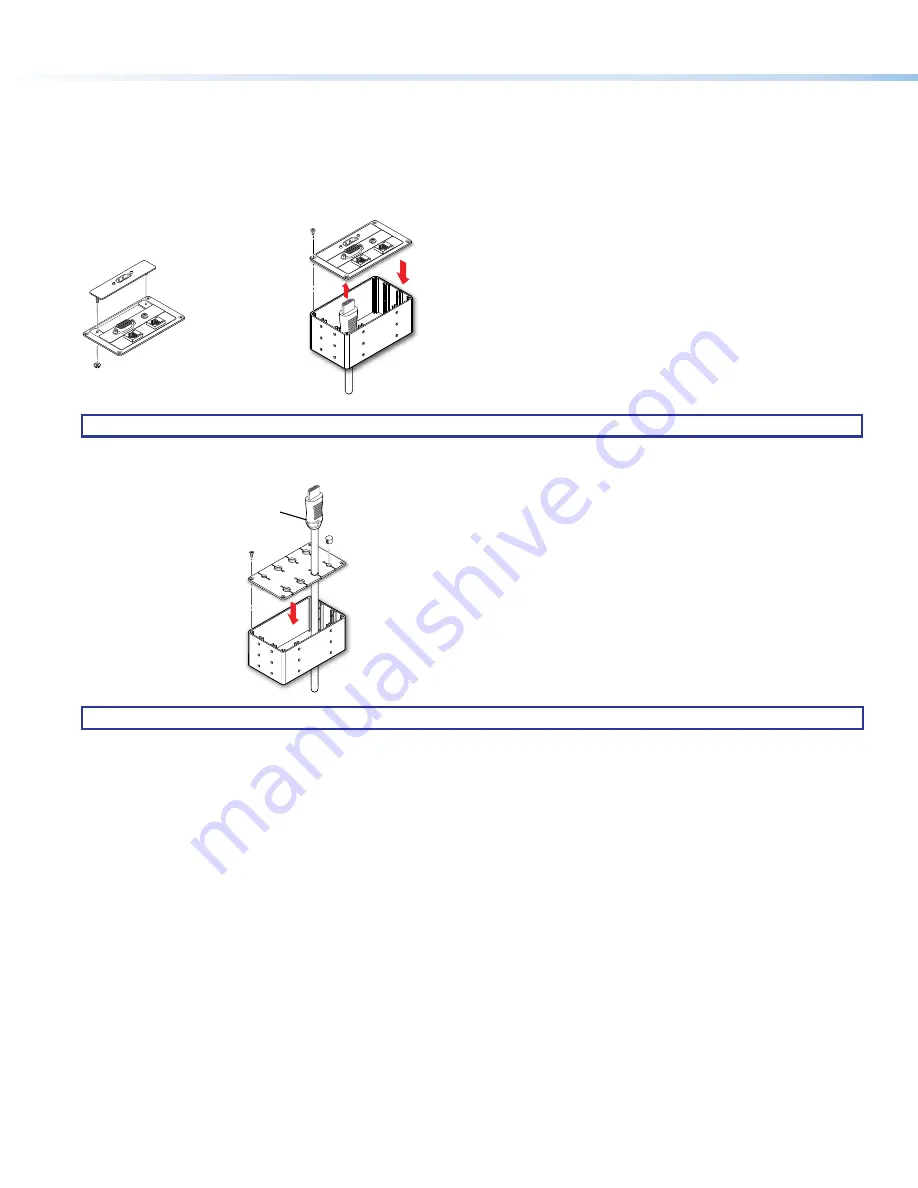

Option 1: AAP module

Secure up to three single-space

AAP modules in the AAP frame

plate.

#4-40 Nut with

Captive Washer

Secure the AAP frame plate on the connectivity

brackets, using four of the provided #4-40 module

screws. Use a screwdriver to tighten the screws.

3

1

2

Insert cables through the bottom of the connectivity bracket.

Connect cables to the AAP modules.

NOTE:

After assembling the module, proceed to

on page 5.

Option 2: Cable pass-through module

Secure the grommet plate

on the connectivity bracket,

using four of the provided

#4-40 module screws. Use

a screwdriver to tighten the

screws.

Insert cables through the bottom

of the connectivity bracket and

into the holes of the grommet plate.

Snap the included

hole plugs into any

unused holes.

3

2

1

NOTE:

After assembling the module, proceed to

.