PPE Inspection form

How to inspect your harness.

Doc: Inspection form - Harness Rev: 9 - Date: 2017-10

Copyright 2017 - Eyolf Inc

If there is any doubt or failure, the harness

should not be used.

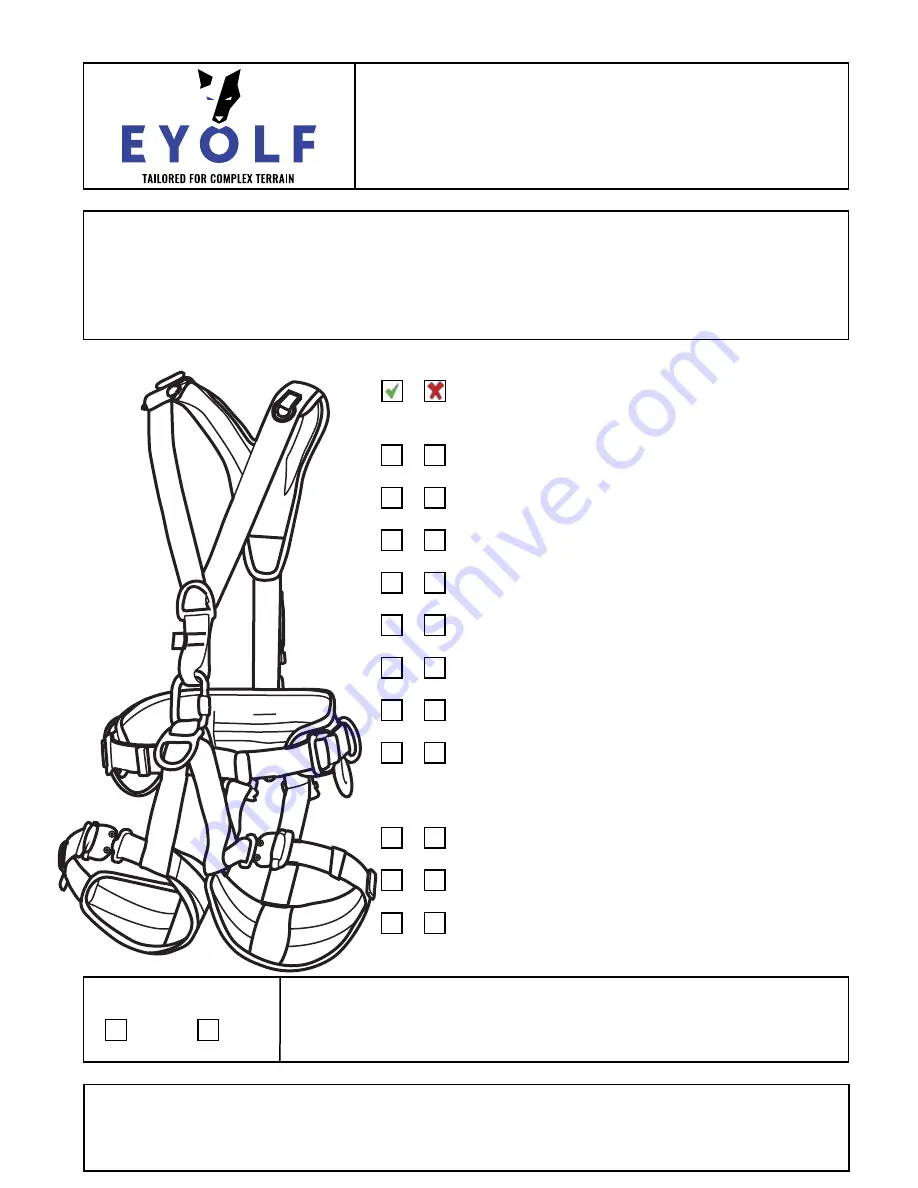

Visual check of the safety components:

Readable labels present?

(Age of harness)

Check webbing

(cuts, burns, wear, chemical marks, other damage)

Check stitching

(cut, worn, coloured or disorderd threads)

Check attachment points

(deformation, cracks, wear, corrosion, burrs, marks)

Check buckles

(deformation, allignment, cracks, wear, corrosion, marks)

Check compatibility of connector

Check condition of protective components

(belay loop, etc.)

Visual check of the comfort components

(padding)

Operational check

Check webbing and buckles are in the right

position

Check adjustments

Check sizing is correct for technician

Owner:

Harness Model:

In Service:

Serial #:

Date of first use:

Date of inspection:

Yes

No

Comments: