PATHWAY HD Code Compliant Modular Access System Installation Manual

Page 14 of 92

2.4.

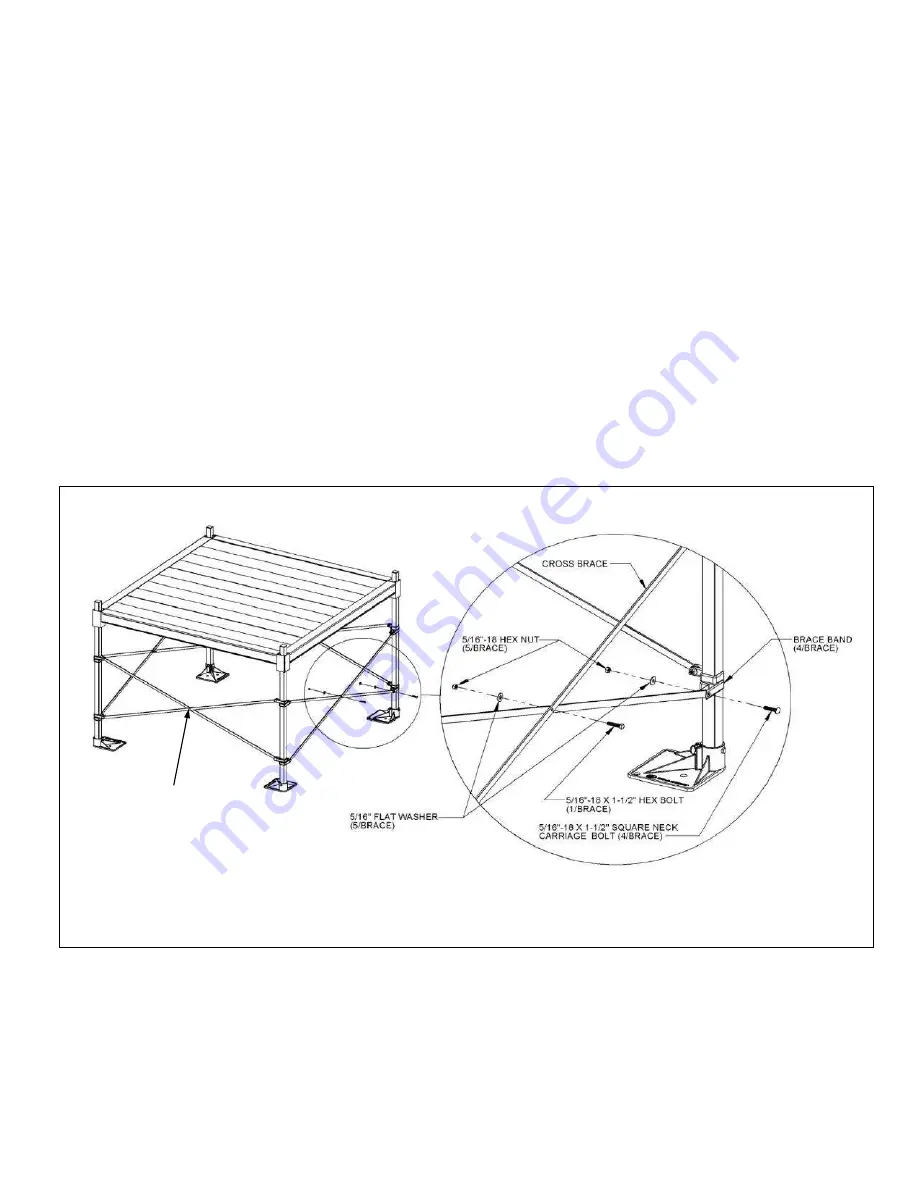

INSTALL CROSS BRACE – PLATFORMS

For added stability, platforms with walking surfaces over 36

″

high require bracing (certain

configurations and site conditions may require bracing under 36”). The TXB36 CROSS BRACE is used

for 5’ and 6’ platform sides and ramps. The TXB736 CROSS BRACE is used for 7’ platform sides.

2.4.1.

Use four braces per platform or six braces when two platforms are connected.

2.4.2.

Separate ends of brace bands until they fit around the 1-1/2” support leg.

2.4.3.

Install four bands on each leg with the part containing bolt holes at 90-degrees from

each other and in line with the outer edge of the foot (FIG. 2.7).

2.4.4.

The cross brace should be placed approximately in the middle of the platform legs on

all four sides with the top brace bands a minimum of two feet from the bottom brace

bands.

2.4.5.

Install the cross brace by installing the 5/16”-18 x 1-1/2” hex bolt, 5/16”-18 hex nut,

and 5/16” flat washer through the center hole in the braces. Tighten enough to hold

the brace together but still allow it to pivot around the bolt (FIG. 2.7).

2.4.6.

If needed for the location, trim the ends of the cross brace to fit.

2.4.7.

Drill one 11/32” or 3/8” diameter hole on center approximately 1/2” from both ends

of each brace.

2.4.8.

Install the assembled cross brace between the legs of the brace bands using the four

5/16”-18 x 1-1/2” long square neck carriage bolts, 5/16”-18 hex nuts, and 5/16”

washers provided (FIG. 2.7).

2.4.9.

Tighten all fasteners securely.

FIG. 2.7

PIVOT POINT

(ALL X-BRACES)