BRAKES

Page D-2

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

GENERAL

How The Hydraulic System Works

A hydraulic system actuates the brakes through two sep-

arate circuits. The rear master cylinder reservoir oper-

ates the front disc brakes, and the front operates the rear

drum brakes. The system transmits the power required to

activate the friction surfaces (pads front and brake shoes

rear) of the braking system from the pedal to the individ-

ual brake units at each wheel.

Hydraulic system operation:

When at rest, the entire system is full of brake fluid. Upon

application of the brake pedal, fluid trapped in front of the

master cylinder piston is forced through the brake lines to

the wheel cylinders. Here, it forces pistons outwards

against the brake pads or shoes.

a) The front brake pad contacts the brake disc and

continued movement of the piston moves the

brake caliper that contains the second brake pad.

The two brake pads apply a clamping force to the

disc.

Upon release of the brake pedal, a spring located

inside the master cylinder immediately returns the

piston to the normal position. The front brake pis-

ton retracts slightly as the piston seal retracts. The

piston returns the brake fluid to its original position

within the rear reservoir of the master cylinder,

and the attached brake pads retract from the disc.

b) Upon release of the brake pedal, a spring located

inside the master cylinder immediately returns the

piston to the normal position. The rear brake shoe

return springs retract the brake shoes and wheel

cylinders which returns the brake fluid to its origi-

nal position within the front reservoir of the master

cylinder.

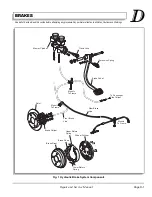

Rear Wheel Brake

The 160 x 30mm hydraulic brake is a leading-trailing

design. The shoes are held to the backing plate by hold-

down springs, pins, and spring retainers. The shoes are

fitted to the anchor at the bottom and secured by a lower

shoe to shoe spring. At the top, the shoe web rests on

the wheel cylinder piston.

The shoes are held to the wheel cylinder pistons by the

upper shoe to shoe spring. The wheel cylinders are a

double piston design, providing even distribution of force

to each shoe. There are no links. Shoes rest directly on

the piston ends. Wheel cylinders incorporate external

boots.

Brake adjustment is automatic (Ref Fig. 2 on page D-3).

Adjustment takes place, if needed, whenever the brakes

are applied (forward or reverse stop or when the vehicle

is stationary). Upon any brake application, the shoes

move outward contacting the drum. As the shoes move

outward, the automatic adjuster levers (attached to each

shoe by a pin) follow the shoe movement. The automatic

adjuster pin is smaller than the slot in the brake shoe

web; therefore, when the brakes are released, the shoes

are allowed to return slightly, providing brake shoe to

drum running clearance.

The rear brake includes a parking feature consisting of a

lever and strut. The lever is applied by a cable attached

to the parking brake lever (hand operated). The parking

brake is used to retain the vehicle when stationary.

Front Disc Brake

The disc brake assembly is a single cylinder, one piece

housing. The cylinder contains a piston and a piston seal

containing a return spring. There are two brake pads, on

either side of the disc. The brake pad mounted to the pis-

ton will move out and in of the cylinder when the brakes

are operated and released. Hydraulic pressure from the

brake master cylinder enters the brake cylinder and

forces the piston and pad against the rotating disc. As

brake pressure continues the piston mounted pad ‘pulls’

the caliper with the second brake pad against the oppo-

site side of the rotating disc. This creates friction to stop

the vehicle.The caliper is held in relative position to the

mounting bracket with sliding pins secured to the caliper.

Maintenance of the single disc brake may include lubri-

cation of slide pins, bleeding, performing operational

checks, and the checking pad and disc wear.

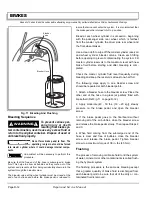

MAINTENANCE

Daily Brake Performance Test

To assure correct braking performance, all peri-

odic maintenance, inspections and procedures

must be performed as indicated in the Periodic Service Sched-

ule in Section A of this manual. It is important that a Daily

Brake Performance Test be performed and the entire brake

system be serviced in accordance with the Periodic Ser-

vice Schedule.

The brake system must be bled whenever any part of the

brake system has been replaced.

Summary of Contents for ST 4X4

Page 6: ...Page iv Repair and Service Manual TABLE OF CONTENTS Notes...

Page 10: ...Repair and Service Manual SAFETY INFORMATION Page viii Notes...

Page 12: ...GENERAL INFORMATION ROUTINE MAINTENANCE Page A ii Repair and Service Manual Notes...

Page 24: ...SAFETY Page B ii Repair and Service Manual Notes...

Page 34: ...BODY AND TRUCKBED Page C ii Repair and Service Manual Notes...

Page 50: ...BRAKES Page D ii Repair and Service Manual Notes...

Page 68: ...CONTINUOUSLY VARIABLE TRANSMISSION CVT Page E ii Repair and Service Manual Notes...

Page 74: ...DIRECTION AND DRIVE SELECTOR Page F ii Repair and Service Manual Notes...

Page 80: ...ELECTRICAL Page G ii Repair and Service Manual Notes...

Page 114: ...FRONT SUSPENSION AND STEERING Page J ii Repair and Service Manual Notes...

Page 128: ...FUEL SYSTEM Page K ii Repair and Service Manual Notes...

Page 136: ...PAINT Page L ii Repair and Service Manual Notes...

Page 142: ...REAR AXLE AND SUSPENSION Page M ii Repair and Service Manual Notes...

Page 152: ...SPEED CONTROL Page N ii Repair and Service Manual Notes...

Page 160: ...TROUBLESHOOTING Page P ii Repair and Service Manual Notes...

Page 168: ...WHEELS AND TIRES Page R ii Repair and Service Manual Notes...

Page 174: ...GENERAL SPECIFICATIONS Page S ii Repair and Service Manual Notes...

Page 180: ...LIMITED WARRANTY Page T ii Repair and Service Manual Notes...

Page 182: ...Page T 2 Repair and Service Manual LIMITED WARRANTY Notes...