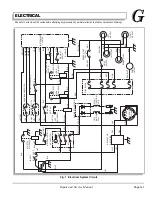

ELECTRICAL

Page G-4

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

TESTING STARTING CIRCUIT

To prevent the possibili-

ty of severe injury or

d e a t h r e s u l t in g f ro m

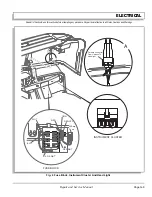

vehicle inadvertently starting, disconnect battery for

steps 2 through 9 (see Section B).

If any DVOM readings indicate a faulty wire, it

is recommended that the condition of the termi-

nals and wire junction be examined. A faulty wire should be

replaced with one of the same gauge and color and wired

between the correct components and wire tied to the harness

bundle. The faulty wire should be cut back close to the harness

and the ends protected with vinyl electrical tape.

Most DVOM’s can be set to give an audible signal if continuity

is present, however readings will generally indicate near

Ω.

Readings greater than 1K

Ω

may indicate a marginal conductor

or joint.

Tool List

Qty. Required

DVOM.......................................................................... 1

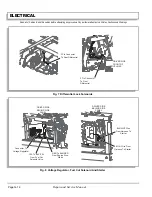

If the engine does not rotate, proceed as follows:

1. Check for a good ground between the battery nega-

tive (-), the frame and the engine.

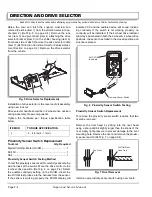

2. Check that vehicle is in neutral (Ref Fig. 1 on page G-

1).

3. Check the battery for a voltage reading which should

be between 12.2 and 12.5 volts. Inspect for loose or

dirty battery post connections.

4. Check for a blown in line fuse and replace if neces-

sary with the recommended amp fuse.

5. Check for loose wires at all terminal connections.

6. Check the complete electrical system for correct cir-

cuitry.

7. Inspect for worn insulation or bare wires touching the

frame. Bare wires will cause a short circuit.

8. Set the DVOM to the ohms (

Ω)

scale. A meter read-

ing of “0”

Ω

indicates continuity. Check for continuity

for white (WHT) wire from battery positive terminal (+)

to the key switch terminal (B) white (WHT) wire. If

continuity is not indicated, there is a fault in the wiring

harness. Check for continuity of the key switch.

Remove key switch plate from instrument panel (Ref

Instrument Panel Replacement section in BODY AND

TRUCKBED). Detach electrical plug from key switch.

Place positive (+) probe on terminal (B) of white

(WHT) wire and negative (-) probe on terminal (S) of

black/white (BLK/WHT) wire. The reading on the

meter should be “0”

Ω

with the switch key in the ‘ON’

position and OL with the switch in the ‘OFF’ position.

If the meter does not register, replace the switch.

Reconnect the wires.

9. Turn the key switch to ‘ON’.

•

Set the DVOM to the ohms (

Ω)

scale and place

one probe on the black/white (BLK/WHT) at the

solenoid. Place the other probe on the key switch

terminal (S) with the black/white (BLK/WHT). If

continuity is not indicated check for continuity at

the neutral switch. If continuity is not indicated,

replace neutral switch. If continuity is indicated

check wiring between key switch (S) and neutral

switch and between neutral switch and starter

solenoid. If continuity is indicated, the starter sole-

noid must be checked.

10. Check the starting solenoid operation. Turn the key

switch to the ‘OFF’ position.

a) Place the DVOM (set to appropriate DC

volts scale) positive (+) probe on the ter-

minal with the black/white (BLK/WHT)

wire solenoid. Place negative (-) probe on

to ground.

b) The DVOM should indicate reference

battery voltage (approximately 12 V).

c) Turn the key switch to the ‘OFF’ position.

The DVOM should indicate 0 V.

d) Replace solenoid if 12 V is not indicated

with the switch turned to ‘ON’.

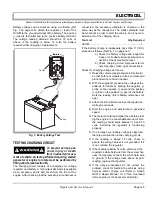

BATTERY VOLTAGE TEST

Hydrogen gas formed

during battery charging

i s e x p l o s i v e a n d c a n

cause severe personal injury or death. Avoid any

electrical spark or open flame near battery.

Do not overcharge battery.

If the temperature of the battery or the

ambient temperature is below 60° F (15° C),

the capacity of the battery will be less. It will require more time

to charge.

A cold battery will build up voltage and more rapidly reduce the

charging rate.

Batteries that are new or have been stored must be fully

charged before being tested or placed in vehicle.

!

!

!

!

Summary of Contents for ST 4X4

Page 6: ...Page iv Repair and Service Manual TABLE OF CONTENTS Notes...

Page 10: ...Repair and Service Manual SAFETY INFORMATION Page viii Notes...

Page 12: ...GENERAL INFORMATION ROUTINE MAINTENANCE Page A ii Repair and Service Manual Notes...

Page 24: ...SAFETY Page B ii Repair and Service Manual Notes...

Page 34: ...BODY AND TRUCKBED Page C ii Repair and Service Manual Notes...

Page 50: ...BRAKES Page D ii Repair and Service Manual Notes...

Page 68: ...CONTINUOUSLY VARIABLE TRANSMISSION CVT Page E ii Repair and Service Manual Notes...

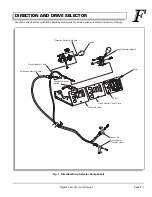

Page 74: ...DIRECTION AND DRIVE SELECTOR Page F ii Repair and Service Manual Notes...

Page 80: ...ELECTRICAL Page G ii Repair and Service Manual Notes...

Page 114: ...FRONT SUSPENSION AND STEERING Page J ii Repair and Service Manual Notes...

Page 128: ...FUEL SYSTEM Page K ii Repair and Service Manual Notes...

Page 136: ...PAINT Page L ii Repair and Service Manual Notes...

Page 142: ...REAR AXLE AND SUSPENSION Page M ii Repair and Service Manual Notes...

Page 152: ...SPEED CONTROL Page N ii Repair and Service Manual Notes...

Page 160: ...TROUBLESHOOTING Page P ii Repair and Service Manual Notes...

Page 168: ...WHEELS AND TIRES Page R ii Repair and Service Manual Notes...

Page 174: ...GENERAL SPECIFICATIONS Page S ii Repair and Service Manual Notes...

Page 180: ...LIMITED WARRANTY Page T ii Repair and Service Manual Notes...

Page 182: ...Page T 2 Repair and Service Manual LIMITED WARRANTY Notes...