1.

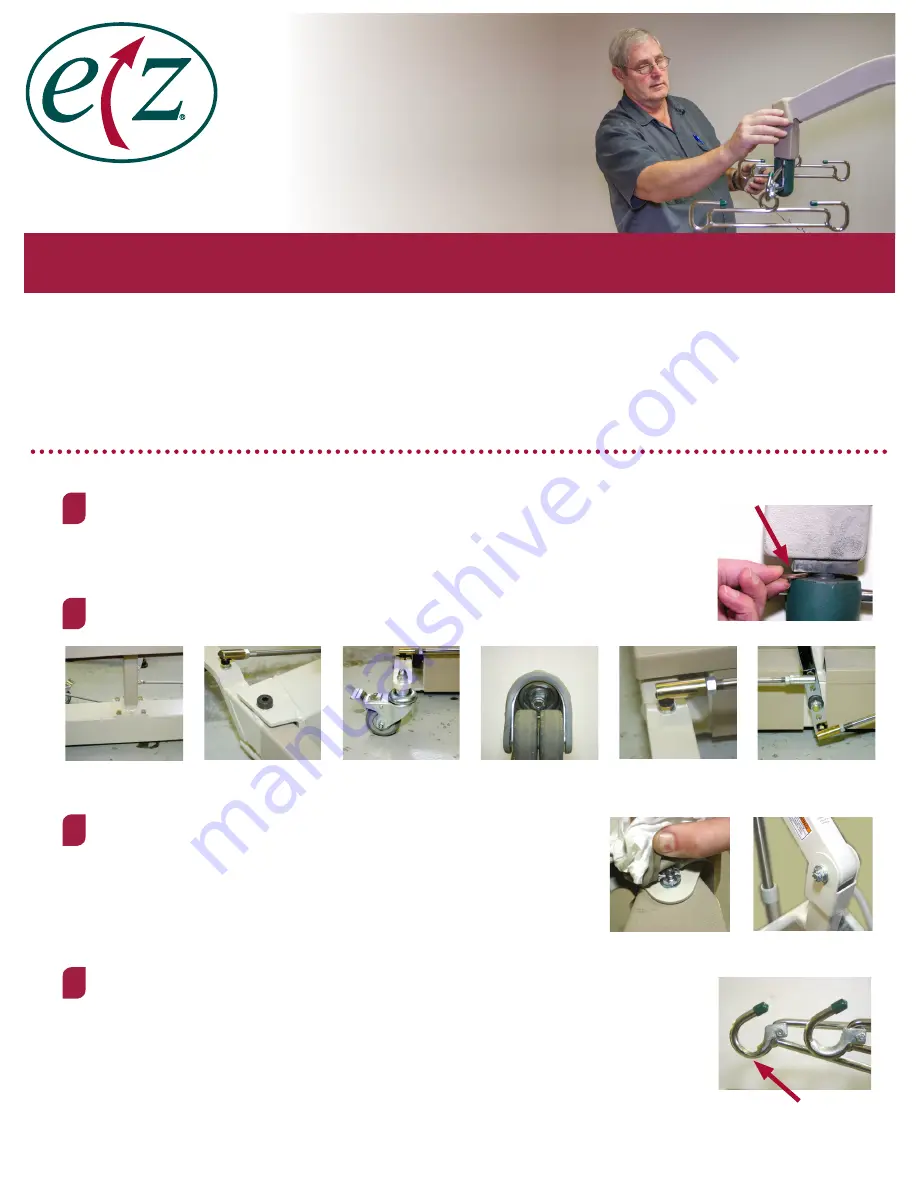

Check wear of hanger assembly bushing

by moving hanger assembly up and down.

If hanger assembly moves up and down and the thickness of 2 quarters can be inserted

between hanger assembly and load cell the hanger assembly needs to be replaced.

2.

Check all bolts

to ensure they are tight.

3.

Check boom to hanger assembly pivot bolt

, peel rubber back to

assure nut is tight and cotter pin is in place. Check boom to mast pivot

bolt by removing plastic cap to assure nut is tight and cotter pin is in

place. If plastic cap is missing order replacement.

4.

Check the point where sling hanger and hanger spreader bar meet

. If excessively

worn, replace the bushings immediately. The hanger spreader and sling hanger wear

points need to be checked for wear. If hooks appear worn, call EZ Way for instructions.

BASE PIVOT REAR WHEEL FRONTWHEEL LINKAGE SPREADER

BADLY WORN

NEEDS REPLACEMENT

BOOM TO MAST

BOOM TO HANGER

EZ Way Smart Lift

®

Safety

&

Maintenance Checklist

EZ Way, Inc.

“Your Total Patient

Lift Solution”

The EZ Way Smart Lift

®

requires a minimum of servicing to keep it in good working order. Nevertheless, it is important that

certain basic checks be periodically made by maintenance staff to ensure on-going safety throughout the life of the device.

The manufacturer suggests that the following components and operating points be scheduled for inspection at intervals not

greater than six months. Any detected deficiency must be rectified before the lift is put back into service.

☐

☐

☐

☐

1

2

3

4