EZG Manufacturing 1-800-417-9272 www.ezgmfg.com

Revision Number-005 09-01-2021 - Present

6

EZG Manufacturing 1-800-417-9272 www.ezgmfg.com

California - Proposition 65 Warning

Engine exhaust and some of its constituents, and some dust created by power sanding,

sawing, grinding, drilling, and other construction activities contains chemicals known to the

State of California to cause cancer, birth defects and other reproductive harm. Some examples

of these chemicals are:

Lead from lead based paints - Crystalline silica from bricks -Cement and other masonry

products -Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: ALWAYS work in a well ventilated area, and work

with approved safety equipment, such as dust masks that are specially designed to filter out

microscopic particles.

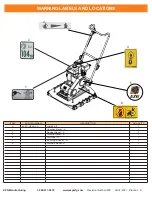

MACHINE DESCRIPTION

1. Throttle

2.

Folding Operating Handle

3.

Handle Adjuster

4.

Belt Guard

5.

Lifting Handle

6.

Roller Bearing Cover

7.

Rubber Coated Compacting Roller

8.

Exciter Housing

9. Engine

10. Lifting Hook

The EVPC120 Roller Compactor is designed for compacting paver slabs into the bedding sand, and to

compact the poly sand into the joints while avoiding cracks, chips, scratches on the paver slabs – and min

-

imizing dust! The EVPC120 weighs 271 lbs. and vibrates at a frequency of 5,640 – perfect for the paving

slab applications as well as many other hardscape installations. Powered by the reliable Honda GX160

gasoline-powered engine, and utilizing four special rubber-coated rollers to protect the paver slabs, the

EVPC120 is just the right machine for the professional hardscape contractor.