EZG Manufacturing 1-800-417-9272 www.ezgmfg.com

Revision Number-012 01-11-2018 - Present

6

EZG Manufacturing 1-800-417-9272 www.ezgmfg.com

California - Proposition 65 Warning

Engine exhaust and some of its constituents, and some dust created by power sanding,

sawing, grinding, drilling, and other construction activities contains chemicals known to the

State of California to cause cancer, birth defects and other reproductive harm. Some examples

of these chemicals are:

Lead from lead based paints - Crystalline silica from bricks -Cement and other masonry

products -Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: ALWAYS work in a well ventilated area, and work

with approved safety equipment, such as dust masks that are specially designed to filter out

microscopic particles.

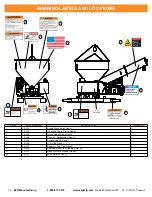

Before operating the Grout Hog® it should be properly set up on the jobsite. The Grout Hog® may be

lifted by using a forklift. The UGPH75 weighs 1475 lbs.(669.0 kg) empty and 4475 lbs.(2029.8 kg) full and

the UGPHC75 weighs 1565 lbs.(709.8 kg) empty and 4565 lbs. (2070.6 kg) full. Check forklift ratings

before attempting to move the Grout Hog®.

1. Rotate hopper to upright position.

2. Slide lift forks into lifting channels on Grout Hog®.

3. Insert skid pins into lift channels behind lift forks and secure with locking pins or use chain attachment.

4. Set Grout Hog® securely on ground. Fill to desired capacity.

5. Transport Grout Hog to desired location and raise above grouting level.

6. Hold discharge hose over area to be grouted.

7. Discharge grout to desired areas until hopper is empty. (Repeat steps 4-7 as needed)

8. To regulate grout flow, squeeze discharge hose; to momentarily stop grout flow, crimp or fold hose.

9. To stop flow for extended period, release button on pendant and hang on provided hook.

OPERATING INSTRUCTIONS

WARNING

This equipment is to be operated by trained and qualified personnel over the age of 18.

Death or serious injury can result.

WARNING

Pins must be in place whenever Grout Hog® is on lift forks. Death or serious injury can

result.

WARNING

Check forklift or crane manufacturer’s specifications to be sure forklift or crane is

designed to handle weight of Grout Hog® and material in hopper. Death or serious

injury can result.

NOTICE

When not in use, store Grout Hog® in tilted position with end cap removed to prevent

water from accumulating in the hopper.