Page G-12

ENGINE

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings.

B

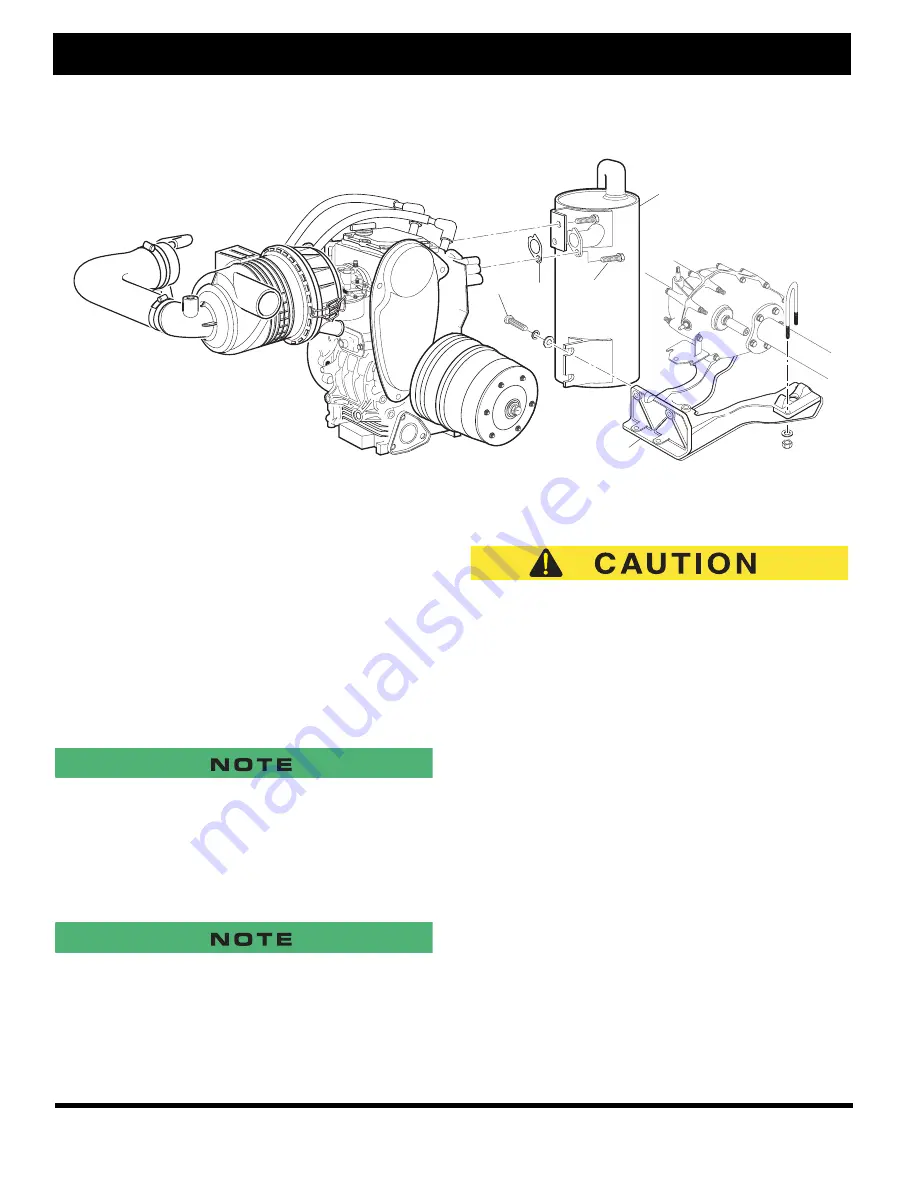

Fig. 23 Engine Assembly

Controls and Wiring

Unplug the wiring harness from the engine and cut the

wire tie securing the accelerator cable to the engine.

Remove the choke cable from the carburetor. Remove

the push nut at the governor and discard the nut.

Remove the pulse line from the fuel pump. Remove the

ground strap from the engine. Loosen the starter/gener-

ator and remove the belt. Remove the short control rod

from the bellcrank and the governor. Remove the short

rod from the bellcrank to the carburetor.

Removing the Engine from the Vehicle

Place suitable blocks under the engine frame for support.

Although the blocks are not required for engine removal, they

will help maintain the alignment of the frames and simplify

engine installation.

Loosen the bolt (3) securing the muffler (4) to the rear

engine frame (5) (Ref. Fig. 23 on Page G-12).

It is not necessary to remove the muffler as part of the engine

removal.

Remove the four bolts (15) that secure the engine to the

engine support castings (13, 17). Lift the engine and

drive clutch vertically through the engine compartment

using a hoist or with the assistance of another person.

Engine Installation

When installing the fuel and pulse lines, pay particular

attention to assure that the lines are not confused.

Be sure to use a new push nut when installing the accel-

erator cable to the governor.

It is important to follow the assembly sequence recom-

mended for mounting hardware.

With the assistance of a hoist or another person, lower

the engine into position over the engine support castings

(Ref. Fig. 24 on Page G-13).

Install one rear horizontal and one front bottom engine

bolt (15) through the casting and engine and lightly snug

in place.

Install the remaining horizontal engine bolts and finger

tighten. Remove the front bottom bolt and reinstall the

skid plate (8) finger tight.

Tighten the bottom and horizontal mounting bolts to 45

ft. lbs. (60 Nm) torque.

The remaining installation is in the reverse order of dis-

assembly using standard torque specifications.

1

2

3

4

5