Page E-3

Repair and Service Manual

B

B

FRONT SUSPENSION AND STEERING

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

Failure of a single spring will result in overstressing the other

spring, therefore it is good practice to replace the front springs

as a set.

Lift and support front of vehicle. (See SAFETY section.)

Support front axle with jack stands.

Remove the front wheels.

Remove the hardware (12) securing the front oQty.f the

damaged leaf spring to the axle (2) (Ref Fig. 1).

Pull the top of the floor mat down. Locate and remove

the hardware (13) securing the rear of the spring to the

vehicle frame.

Install a new spring by first attaching the rear of the

spring to the vehicle frame with hardware (13) and then

installing the front of the leaf spring to the axle with hard-

ware (12).

Repeat for the other side.

If a spring is replaced, the axle will need to be aligned to the

frame. Unless the axle has been replaced, this will not affect

the wheel alignment. It is always good practice to check the

wheel alignment any time the front-end components are

replaced or adjusted.

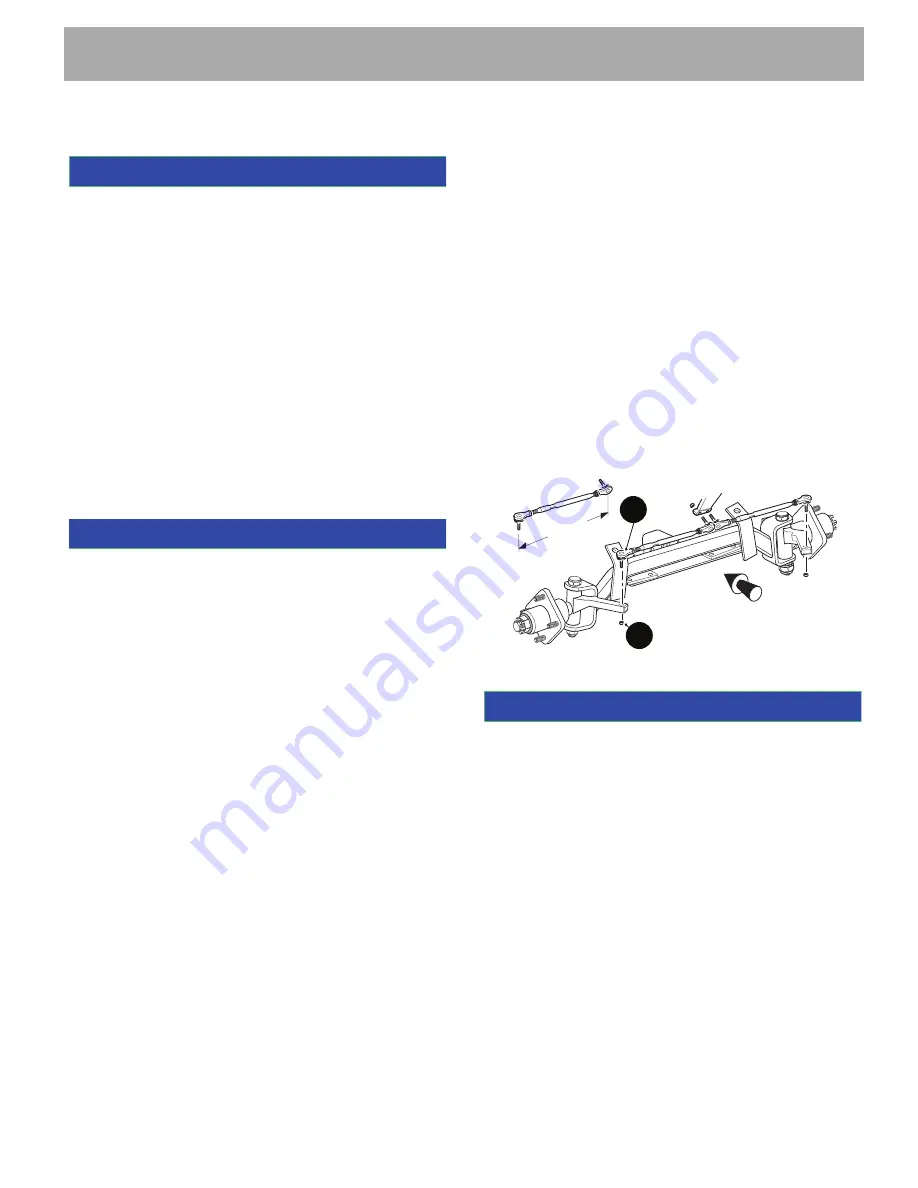

When springs are replaced, the front axle must be

aligned to the frame. The distance from the center bolt

at rear of left spring to the center bolt at front of right

spring must be the same as the distance from the center

bolt at rear of right spring to the center bolt at front of left

spring. (Ref Fig. 2) Tighten the spring hardware to 35 -

50 ft. lbs. (50 - 70 Nm) torque.

Replace front wheels per WHEELS AND TIRES section

and lower vehicle.

Tie Rod, Wheel Bearing and King Pin Inspec-

tion

Grasp the tie rod and check for any vertical motion

which would indicate a worn condition and require

replacement. Grasp the top and bottom of the wheel and

use a rocking motion to check for excessive king pin or

wheel bearing movement which indicates a worn or

loose condition.

Tie Rod Replacement

Tool List

Qty.

Wheel chocks .............................................................. 4

Floor jack..................................................................... 1

Jack stands ..................................................................2

Pliers............................................................................1

Impact wrench .............................................................1

Impact socket, 3/4" ......................................................1

Impact socket, 11/16"...................................................1

Torque wrench, ft. lbs...................................................1

Ball joint separator .......................................................1

Wrench, 3/4" ................................................................1

Lift and support front of vehicle per SAFETY section.

Remove front wheels.

Remove the nut (1) from the ball joint (2) (Ref Fig. 3).

Insert a ball joint separator between the ball joint and the

linkage and separate the ball joint from the linkage at

both ends.

Fig. 3 Tie Rod Replacement

A worn tie rod is likely to be out of adjustment. The vehicle will

require a wheel alignment before being returned to service.

(Ref Fig. 12)

Adjust tie rod to 12 1/2" (31.7 cm) between center of tie

rod ends and install in reverse order of disassembly.

(Ref Fig. 3) The nut (1) should be tightened to 35 ft. lbs.

(50 Nm) torque.

Once the tie rod has been replaced, the front wheel toe-

in will need to be checked and adjusted as necessary.

See ‘Wheel Alignment’ later in this section.

STEERING

Steering Wheel Replacement

Tool List

Qty.

Phillips screwdriver ......................................................1

Socket, 15/16" .............................................................1

Ratchet ........................................................................1

Plastic faced hammer ..................................................1

NOTICE

NOTICE

12

1/2

"

(31

.7 c

m)

Front of Vehicle

1

2

NOTICE

Summary of Contents for EXPRESS L4

Page 6: ...Page iv Repair and Service Manual NOTES TABLE OF CONTENTS ...

Page 207: ......