Repair and Service Manual

B

B

FRONT SUSPENSION AND AXLE MOUNTED STEERING

Read all of Section B and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

To install new rack ball joint close to its correct position,

measure amount of threads exposed from jam nut (Ref

Fig. 26).

Fig. 26 Rack Ball Joint Installation

Loosen jam nut (4) and remove rack ball joint from rack

extension (5).

Using measurement made earlier, thread jam nut and

new rack ball joint to previous location on rack extension

and set jam nut hand tight.

Attach rack ball joint to spindle arm. Tighten castellated

nut (3) to 36 ft. lbs. (50 Nm) torque and continue to

tighten as needed to insert new cotter pin (2). Maximum

torque is 50 ft. lbs. (70 Nm).

After replacing or servicing steering components, always

verify that an 1/8" gap exists between large hex of rack

extension and rack and pinion unit when steering is

turned fully to the right forcing passenger spindle arm

against front axle (Ref Fig. 34).

Check for proper rack extension-to-rack and pinion unit

clearance before tightening jam nut (4) to 35 - 45 ft. lbs.

(47 - 61 Nm) torque. “Checking/Adjusting Rack Exten-

sion-to-Rack and Pinion Unit Clearance” on page E - 25.

Install passenger side front wheel per WHEELS AND

TIRES section and lower vehicle per SAFETY section.

Check front wheel alignment and adjust if necessary.

“Wheel Alignment” on page E - 13.

Tie Rod Inspection/Replacement

Tool List

Qty.

Tape Measure.............................................................. 1

Wrench, 3/4"................................................................ 1

Wrench, 9/16" ..............................................................1

Needle Nose Pliers ......................................................1

Wrench, 11/16" ............................................................1

Ball Joint Separator .....................................................1

Plastic Faced Hammer ................................................1

Socket, 11/16"..............................................................1

Torque Wrench, ft. lbs. .................................................1

Crowfoot Socket, 3/4" ..................................................1

Grasp the tie rod (8) at ball joints (6) and check for any

vertical motion which would indicate a worn condition

and require replacement (Ref Fig. 25).

To remove tie rod, loosen wheels and lift and support

front of vehicle per SAFETY section.

Remove front wheel.

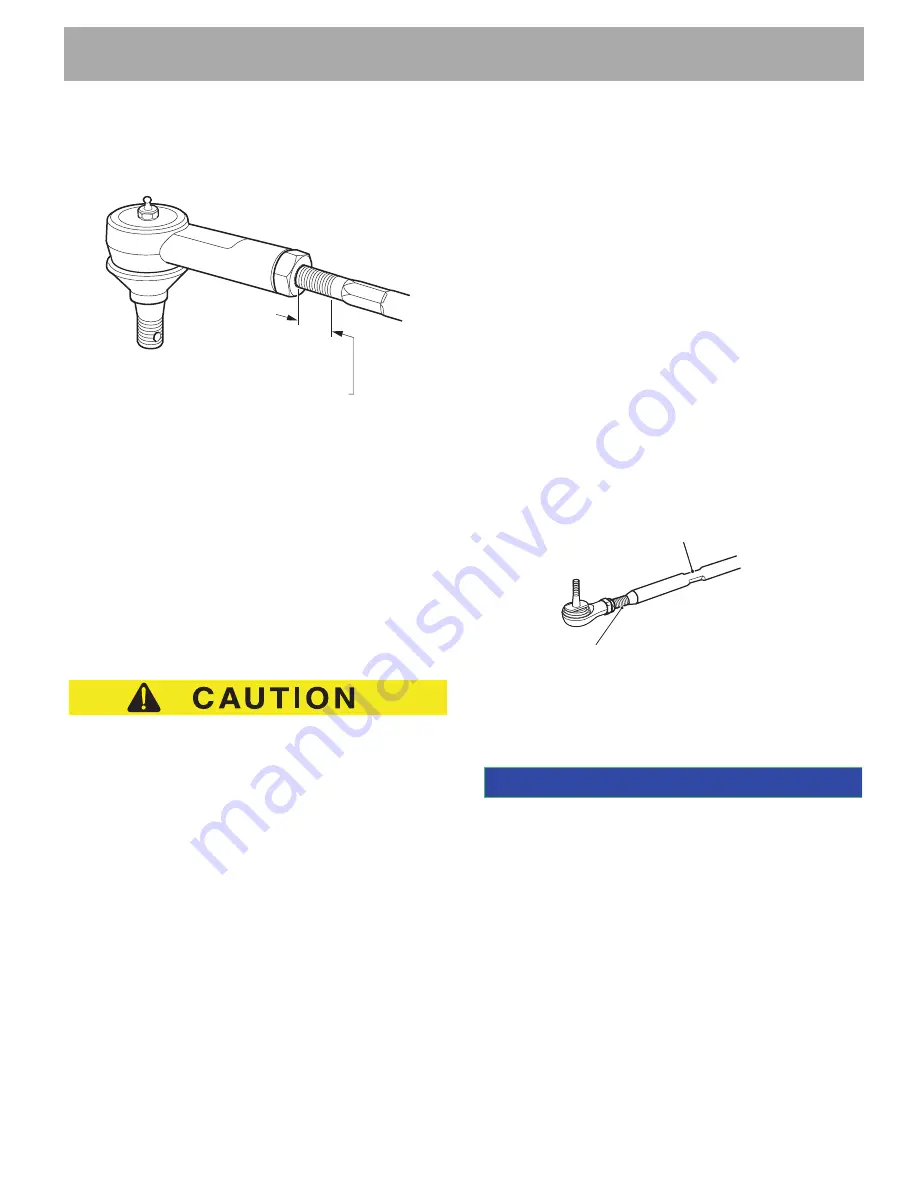

To install new tie rod ball joint close to its correct posi-

tion, measure the exposed thread length from jam nut

(Ref Fig. 27).

Fig. 27 Tie Rod Replacement

Loosen jam nut (7) at threaded tube (8).

To hold threaded tube while loosening jam nut, use a

wrench on the center, flat section of tube (Ref Fig. 25).

The tie rod has different threads on each end. The end

with

the flat area on the threaded tube has left hand

threads (clockwise to loosen) while the end

without

the

flat has conventional right hand threads (counter-clock-

wise to loosen) (Ref Fig. 27).

Remove lock nut (10) until tie rod ball joint (6) threads

are protected. Using a ball joint separator as a lever,

apply pressure to ball joint and tap nut with plastic faced

hammer to release tie rod from spindle arm. Remove nut

to drop tie rod from spindle arm.

Unscrew tie rod ball joint and jam nut from threaded

tube.

Measure exposed thread length

and use length to position new

ball joint at same location

Flat section towards end identifies

end with left hand threads

Measure threads showing for length to

position new ball joint at same location

NOTICE

Page E-21

Summary of Contents for EXPRESS L4

Page 6: ...Page iv Repair and Service Manual NOTES TABLE OF CONTENTS ...

Page 207: ......