Page K-6

ELECTRICAL COMPONENTS & WIRING

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings.

B

21. Replace the controller splash shield and secure it to

the body with two Torx head screws.

22. Connect the negative battery wires using an insulated

wrench.

23. Connect the positive battery wires using an insulated

wrench.

24. Be sure that all wires are connected properly before

installing the body components that were removed to

allow access to the wiring harness.

REPLACING ELECTRICAL COMPO-

NENTS

Run / Tow Switch

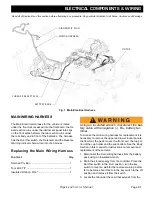

(Ref Fig. 17 on page K-6)

Tool List

Qty.

Notched Pry Bar .......................................................... 1

Torx Bit 27 IP ............................................................... 1

Wire Cutters................................................................. 1

Wire Stripper................................................................ 1

Wire Terminal Crimping Tool........................................ 1

Insulated Wrench, 9/16" .............................................. 1

Using an insulated wrench, disconnect the bat-

tery cable at the negative (-), BL-, battery ter-

minal.

To access the splash shield where the run/tow switch is

mounted, raise and remove the seat bottom. The splash

shield is mounted over the controller on the passenger

side of the vehicle.

1. Disconnect the battery cable at the negative (-) battery

terminal using an insulated wrench.

2. Remove two Torx head screws and the christmas tree

rivet securing the controller splash shield to the rear

body, raise splash shield and turn over to expose the

switch and wires.

3. Remove the seal and upper nut to allow the switch to

be removed from the splash shield.

Check the Run /

Tow label, if it has become difficult to read replace

it with a new one available from service parts.

4. Cut the wires from the existing run/tow switch close to

the switch.

5. Strip insulation from the end of each wire, using a butt

splice connector and heat shrink tubing connect the

wires from the new run/tow switch to the wire harness.

6. Remove the upper nut and seal (7) from the new

switch (8).

7. Install the switch (8) with the notch towards the RUN

direction.

8. Install the upper nut and seal (7) finger tight and

torque as specified in the torque table.

Fig. 17 Run / Tow Switch

9. Install the splash shield using the two Torx screws to

secure the shield to the body and a new christmas

tree rivet

Replace any worn or damaged hardware with new as

required

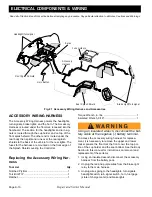

Reverse Warning Indicator

(Ref Fig. 18 on

page K-7)

Tool List

Qty.

Notched Pry Bar ..........................................................1

Torx Bit 27 IP ...............................................................1

Wire Cutters.................................................................1

Wire Stripper ................................................................1

Wire Terminal Crimping Tool........................................1

Insulated Wrench, 9/16"...............................................1

Using an insulated wrench, disconnect the bat-

tery cable at the negative (-), BL-, battery ter-

minal.

To access the splash shield containing the run/tow

switch raise and remove the seat bottom.

ITEM

TORQUE SPECIFICATION

7

13 in. lbs (1.5 Nm) Max.