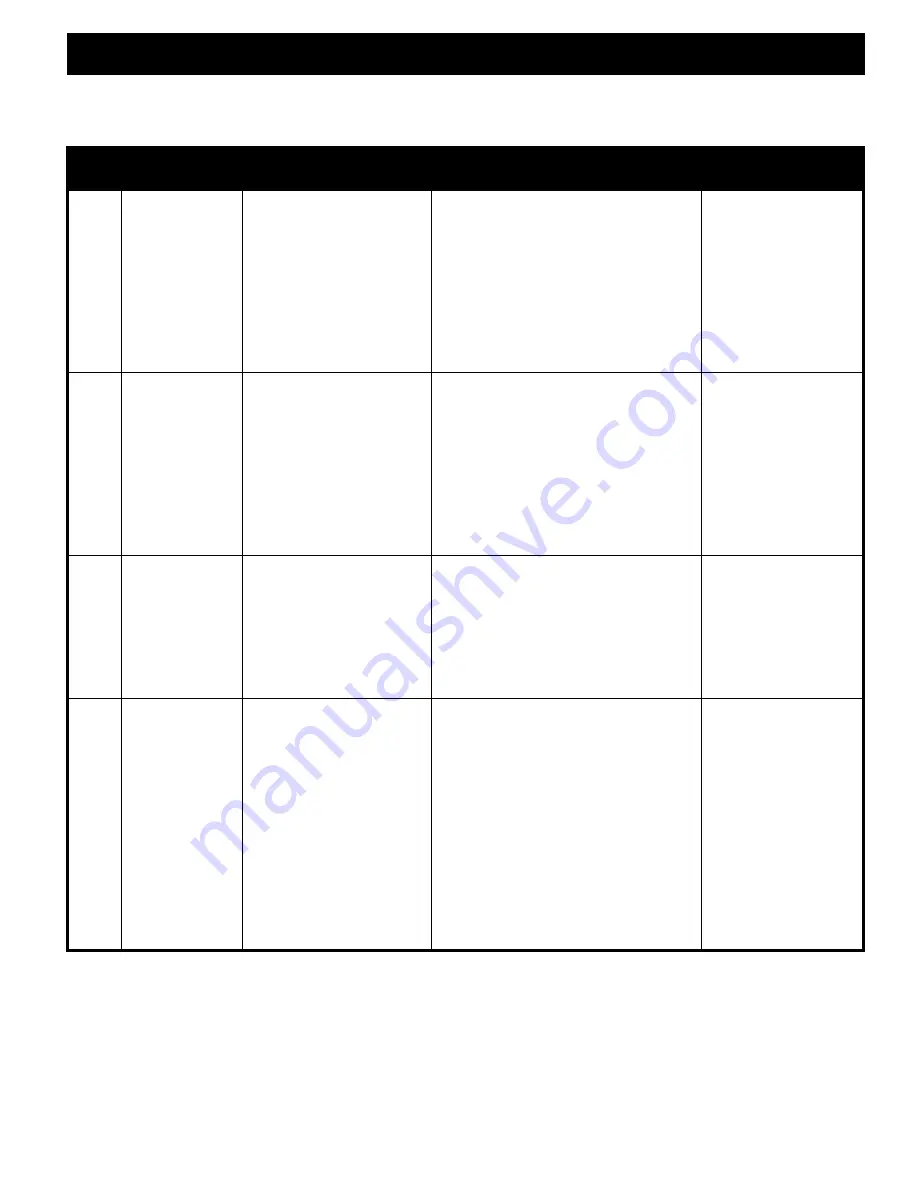

TROUBLESHOOTING AND DIAGNOSTICS

Page O-5

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings.

B

B

CODE

DESCRIPTION

POSSIBLE CAUSES

DIAGNOSTIC STEP

ACTION (post diagnos-

tics)

8976

AC Over Current

1. Software detects motor cur-

rent 50% higher than controller

peak rated current. NOTE: this

error is seldom seen. It is usu-

ally the result of motor parame-

ters such as stator inductance

or resistance being out of spec.

Transient Events can also

cause this error without a com-

ponent failure

1. Turn key to ’OFF’ and then back ’ON’. If

car does not run proceed to step 2.

2. Disconnect U, V, W from controller. Check

resistance between U -V, V-W, and U-W,

each should be 0.4-0.8 Ohms. If readings

are out of range see

ACTION

1

. If readings

are in range and car does not run proceed to

step 3.

3. Remove controller from the non-running

car and install it in a running car, if this vehi-

cle does not run with this controller the con-

troller is suspect. See

ACTION 2

1. Replace Motor

2. Replace Controller

9024

AC Short Circuit

1. Short circuit detected in con-

troller, motor cable or motor.

1. Turn key to ’OFF’ and then back ’ON’. If

car does not run proceed to step 2.

2. Disconnect U, V, W from controller. Check

resistance between U -V, V-W, and U-W,

each should be 0.4-0.8 Ohms. If readings

are out of range see

ACTION 1

. If readings

are in range and car does not run proceed to

step 3.

3. Remove controller from the non-running

car and install it in a running car, if this vehi-

cle does not run with this controller the con-

troller is suspect. See

ACTION 2

1. Replace Motor

2. Replace Controller

12576 DC Bus Timeout

1. DC Bus voltage has not

reached 24 volts within 10 sec-

onds after key switch start.

1. Check battery voltage across all 4 batter-

ies, voltage should read 42 VDC minimum, if

O.K. proceed to step 2.

2. Check voltage across solenoid contacts, if

more than 3 VDC but less than 24 VDC pro-

ceed to step 3, if not see

ACTION 3

.

3. Remove resistor control module connec-

tion to controller B- terminal, if error status

changes follow

ACTION 1

.

1. Replace resistor control

module.

2. If error does reoccur

then replace controller.

3. Replace solenoid.

12817 DC Bus High - Soft-

ware Detected

1. Battery Pack voltage is over

63 volts. NOTE: It is unlikely

this error will occur in the fac-

tory. If it occurs in the field dur-

ing regenerative braking,

energy is transferred from the

controller back to the battery

pack raising the DC Bus volt-

age and battery pack terminal

voltage only if the energy burn

circuit is not properly function-

ing.

1. Verify that all battery wires are securely

fastened and have less than 0.1 ohms resis-

tance between wire terminal and battery

post.

2. Check the battery voltage across all 4 bat-

teries, voltage should read 63 VDC

MAXI-

MUM

.

3. Check voltage across solenoid contacts. If

more than 3 VDC but less than 24 VDC pro-

ceed to step 3, if it does not fall in this range

follow

ACTION 3

.

4. Verify power resistor ohm reading is

between 0.2 and 0.5 ohms.

5. Remove resistor control module connec-

tion to controller B- terminal. If error status

changes follow

ACTION 1

.

1. Tighten or replace loose

or high resistance power

wire connections.

2. Replace power resistor.

3. Replace solenoid.

4. Replace resistor control

module.

5. If error continues,

replace the controller.