TROUBLESHOOTING AND DIAGNOSTICS

Page O-12

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings.

B

B

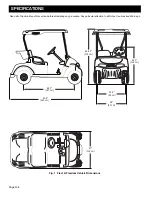

DIGITAL VOLT OHM METER

A typical DVOM (digital volt ohm meter) is shown. A rec-

ommended model is available through the Service Parts

Department as P/N 27481-G01. For the purpose of this

section, the red probe (+) and black probe (-) are used.

Any DVOM may be used, however the controls, dis-

plays, accuracy and features may vary depending on the

make and model. Always follow the meter manufactur-

er’s recommendations and instruction for the use and

care of the meter.

Fig. 2 DVOM

TROUBLESHOOTING

In order to effectively troubleshoot the circuits that in-

clude the horn, lighting, brake/turn signals and gauges,

the technician must be able to use the wiring diagram

and a DVOM.

The wiring diagram shows the path followed by voltage

or a signal from its origination point to its destination.

Each wire is indicated by color.

The technician should use simple logic troubleshooting

in order to reduce the number of steps required to iso-

late the problem.

Example 1: If the vehicle will not start or none of the

lights function (or burn dimly) the battery should be test-

ed before trying to troubleshoot the lighting circuit.

Example 2: If a problem occurs in the lighting circuit that

results in only one of the headlights not working, there is

no reason to check battery wiring or the fuse since it is

obvious that voltage is present. Since bulbs will burn out

over time, the obvious place to start is at the headlight

that is not functioning. if power is present at the connec-

tor and the ground wiring is satisfactory, the only possi-

bilities that exist are a burned out bulb or a poor contact

between the connectors and the headlight.

If power is not present but the other headlight functions,

a wiring problem is indicated between the two head-

lights.

In some cases where battery voltage is expected, the

easiest way to test the circuit is to set the DVOM to DC

volts and place the negative (-) probe of the DVOM to

the negative battery terminal. Move the positive (+)

probe to each wire termination starting at the battery and

working out to the device that is not working. Be sure to

check both sides of all switches and fuses.

When no battery voltage is found, the problem lies

between the point where no voltage is detected and the

last place that voltage, was detected. In circuits where

no voltage is expected, the same procedure may be

used except that the DVOM is set to continuity. Place

the negative (-) probe on a wire terminal at the begin-

ning of the circuit and work towards the device that is

not working with the positive (+) probe. When continuity

is no longer indicated, a failed conductor or device is

indicated.

ACCESSORY WIRING HARNESS

After determining that there is power to the fuse and the

fuse is good, continue checking the circuit using the pro-

cedures previously used to check the power supply, i.e.

loose or rusted connections, bare wires, continuity of the

wiring from terminal to terminal, operating condition of

switch, etc.

Use the wiring diagram to check correct wiring and wire

routing. If there is power at the fuse end of the wire,

there must also be power at the other end of the wire at

the switch or electrical accessory, and eventually at the

ground connection. Electricity must flow from the fuse

through the full length of the circuit to the ground con-

nection. Any interruption of electricity flow must be cor-

rected, whether by repairing or replacing the wire, the

switch or the accessory.

COVER

DATA-H

SWITCH

RANGE

SWITCH

TRANSISTOR

SOCKET

+ TEST LEAD

- TEST LEAD

TEST RECEPTACLES

FUNCTION SELECTOR

SWITCH

CONTINUITY TEST

DIODE TEST, AC/DC

CURRENT TOGGLE

SWITCH

DIGITAL DISPLAY