protect against electric shock in the event of

failure of the basic insulation.

GUIDELINES FOR USING EXTENSION CORDS

f

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one

heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

f

Always replace a damaged extension cord or have it

repaired by a qualified person before using it.

f

Protect your extension cords from sharp objects,

excessive heat and damp/wet areas.

f

Use a separate electrical circuit for your tools. This

circuit should be protected with the appropriate

time-delayed fuse. Before connecting the motor to

the power line, make sure the switch is in the OFF

position and the electric voltage is rated the same

as the voltage stamped on the motor nameplate.

Running at a lower voltage will damage the motor.

PRODUCT SPECIFICATIONS

INTENDED USE

The machine is intended for cutting, roughing and

brushing of metal and stone materials without the

use of water.

NOISE/VIBRATION INFORmATION

The vibration level given in this information sheet

has been measured in accordance with a stan-

dardized test given in EN 60745 and may be used

to compare one tool with another. It may be used

for a preliminary assessment of exposure. The

declared vibration emission level represents the

main applications of the tool. however if the tool

is used for different applications, with different

accessories or insertion tools or is poorly main-

tained, the vibration emission may differ. This

may significantly increase the exposure level over

the total working period.

An estimation of the level of exposure to vibra-

tion should also take into account the times when

the tool is switched off or when it is running but

not actually doing the job. This may significantly

reduce the exposure level over the total working

period.

Identify additional safety measures to protect the

operator from the effects of vibration such as:

maintain the tool and the accessories, keep the

hands warm, organization of work patterns.

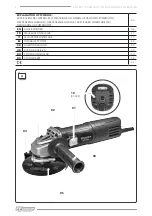

IDENTIFICATION

1.

On/Off switch

2. Spindle lock button

3. Auxiliary handle

4. Protective guard

5.

Release lever for protection guard

6. Spindle

7.

Clamping flange

8. Spanner

9.

Mounting flange

10. Speed Preselection thumbwheel (45 589)

USE

mOUNTING OF ACCESSORIES (E)

f

Clean spindle

(6)

and all parts to be mounted.

f

Tighten clamping flange

(7)

with spanner

(8)

while

pushing spindle-lock button

(2)

.

f

For removing accessories handle vice-versa.

mOUNTING OF AUxILIARy HANDLE (C)

Screw the auxiliary handle

(3)

on the right or left

of the machine head depending on the working

method.

REmOVING / mOUNTING / ADjUSTING OF pRO-

TECTIVE GUARD (B)

f

Open the guard by releasing the lever

(5)

f

Place protective guard

(4)

on the spindle collar

and

turn it to the required position (depending on the

work to be carried out).

f

Adjust protective guard

(4)

by pushing the lever

(5)

.

BEFORE USING THE TOOL

f

Ensure that accessory is correctly mounted and firm

-

ly tightened.

f

Check if accessory runs freely by turning it by hand.

f

Test-run tool for at least 60 seconds at highest no-

load speed in a safe position.

f

Stop immediately in case of considerable vibration

or other defects and check tool to determine the

cause.

SWITCHING ON AND OFF (D)

f

To start the power tool, push the on/off switch

(1)

forward.

f

To lock the on/off switch

(1)

in position, push the on/

off switch

(1)

forward and down until it clicks into

place.

f

To switch off the power tool, release the on/off

switch

(1)

; or, if the switch is locked, briefly push the

on/off switch

(1)

backward and down and then re-

lease it.

SpEED pRESELECTION (45 589)

You can preselect the required speed using

the speed preselection thumbwheel

(10)

, even

during operation.

ROUGH GRINDING

The best roughing results are achieved when set-

ting the machine at an angle of 30° to 40°. Move the

machine back and forth with moderate pressure. In

this manner, the workpiece will not become too hot,

does not discolor and no grooves are formed.

CUTTING

f

Do not tilt the tool while cutting.

f

Always move the tool in same direction as arrow on

tool head, in order to prevent the tool from being

pushed out of the cut in an uncontrolled manner.

f

Do not apply pressure on the tool; let the speed of

the cutting disc do the work.

f

The working speed of the cutting disc depends on

the material to be cut.

f

Do not brake cutting discs with side pressure.

English |

9

www.ffgroup-tools.com

AG 125/1010 HD | AG 125/1200E HD | AG 125/1400C HD