| English

10

4. Non-intended use.

5.

Electrical system breakdown due to power of

the machine in a manner not compliant with the

electric and VDE regulations.

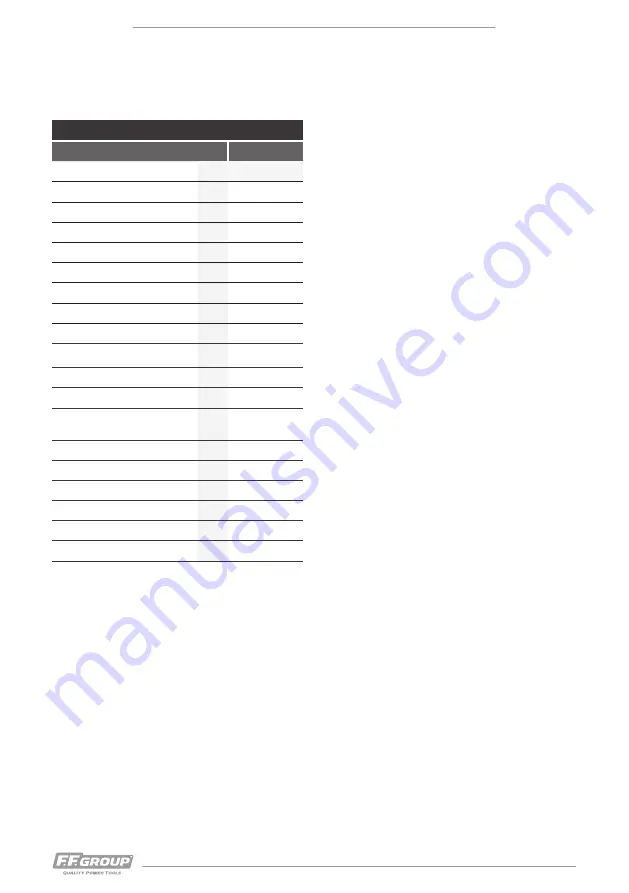

TECHNICAL DATA

Article Number

47 484

Model

EXTREMIG 200

Voltage

V

230

Frequency

Hz

50/60

Max rated input current

A

36

Rated capacity

kVA

8.3

No load voltage

V

68

Welding voltage

V

15,5~24

Rated duty cycle

15%

Welding Wire diameter

mm

0,6 - 1,0

Wire feed speed

m/

min

2 - 10

Rated welding current (MIG)

A

200

Current adjustment (MIG)

A

30 - 200

Rated welding current

(STICK)

A

170

Current adjustment (STICK)

A

30 - 170

Insulation grade

F

IP

IP21S

Cooling

Air

Weight

kg

11

Dimension (LxWxH)

cm

49,4x22x38

IDENTIFICATION (FIG. 1)

1. Control panel

2.

Ground lead output

3.

Possitive lead output

4.

MIG output

5.

ON/OFF switch (other side)

OPERATION

PREPARING THE UNIT

Unpacking and completing the assembly should

be done on a flat and stable surface, with enough

space for moving the machine and its packaging,

always making use of suitable equipment.

WARNING

Always unplug your machine from power source be

-

fore any adjustment.

OPERATING THE UNIT

WARNING

Connect ground lead as close to the area being weld-

ed as possible to ensure a good ground. Do not allow

any body part to come in contact with the welding

wire if you are in contact with the material being

welded, ground or electrode from another welder.

Do not drape cables over or around your body. Do

not overuse or overheat your welder. Allow prop

-

er cooling time between duty cycles. Do not point

torch at any body part of yourself or anyone else.

Always use this welder in the rated duty cycle to pre-

vent excessive heat and failure.

On the machine you will find the data table with

the below information:

X = Duty cycle

I1max = Maximum rated input current

I1eff = Maximum effective input current

I2 = Rated welding current

U0 = No load rated voltage

U1 = Rated input voltage

U2 = Loading voltage

NOTE

Suitable welding wire diameter should be selected

according to the welding job about to undertake.

MAINTENANCE AND CLEANING

WARNING

For your own safety, turn the switch off and remove

plug from power source outlet before any operation

of maintenance on the machine.

Keep your appliance clean. In order to avoid

overheating of the motor, regularly check the air

openings for any dust sticking on. After a longer

period of use, it is recommended to have the ma

-

chine checked by an authorized dealer service.

Connections and repairs of electrical equipment

may only be carried out by an electrician.

POWER CORD

To avoid shock or fire hazard, if the power cord is

worm or cut, or damaged in any way, have it re

-

place immediately. Electrical connection cables

often suffer insulation damage. Possible causes

are:

f

Punch points when connection cables are run

through window or door gaps.

f

Kinks resulting from incorrect attachment or lay

-

ing of the connection cable.

f

Cuts resulting from running over the connecting

cable.

f

Insulation damage resulting from forcefully pull

-

ing out of the wall socket.

f

Cracks through aging of insulation.

Such defective electrical connection cables must

not be used as the insulation damage makes them

extremely hazardous.

CLEANING

Use a small soft brush to clean the outside of the

unit. Do not use strong detergents. Household

cleaners that contain aromatic oils such as pine

and lemon and solvents such as kerosene can

damage plastic housing or handle. Wipe off any

moisture with a soft cloth. Remove dust, dirt and

machining residues with an appropriate vacuum

cleaner if necessary.

EXTREMIG 200