English |

9

www.ffgroup-tools.com

GVE 174 N1 PLUS | GVE 200 N1 PRO | GVE 200 N2 PRO

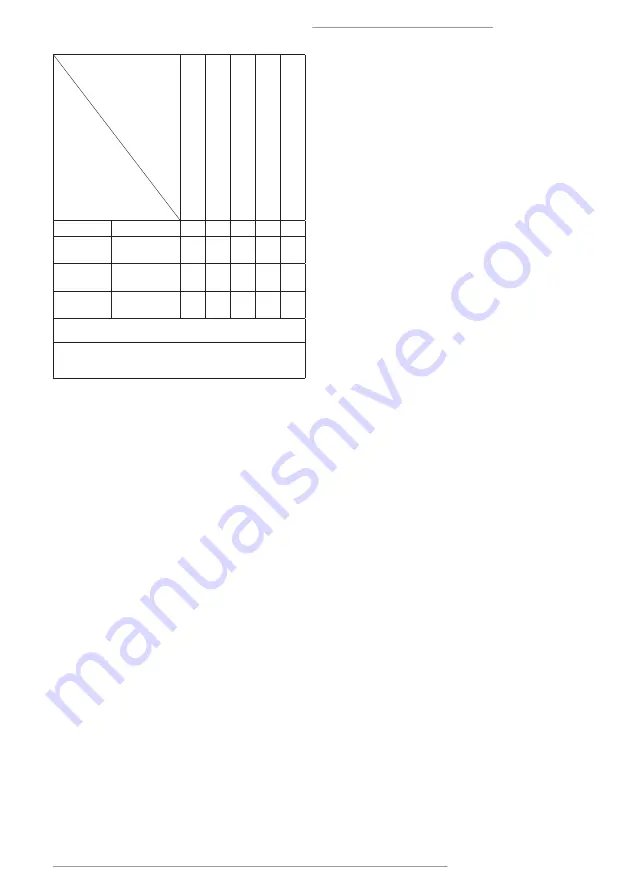

Items

B

ef

or

e e

ac

h u

se

A

ft

er 1

st m

on

th o

r fi

rs

t 2

0h

rs o

f o

pe

ra

ti

on

Ev

er

y 3 m

on

th

s o

r 5

0h

rs o

f o

pe

ra

ti

on

Ev

er

y 1

2 m

on

th

s o

r 1

00

hr

s o

f o

pe

r

at

io

n

Ev

er

y 2

4 m

on

th

s o

r 2

50

hr

s o

f o

pe

r

at

io

n

Fuel tank

Check-Clean **

√*

Deposit cup

(if available)

Clean

√

√

Valve clear

ance

Check-Ad

just **

√

Combustion

chamber

Check-Clean **

√*

*These items should be replaced if needed.

**These operations should be carried out only by authorised

dealer, that have the appropriate tools and the required

mechanical proficiency.

ENGINE OIL

WARNING:

Checking the level and changing the oil

should be done in solid and level ground. The engine

has to be stopped at all times. If the engine had been

running, it will be hot and the procedure should be

done with care in order to avoid burn danger.

To check the oil level:

1. Remove the oil filler cap.

2. Wipe the oil dipstick clean.

3. Insert the oil dipstick into the oil filler neck,

without screwing it.

4. Remove the oil dipstick and check the oil level

shown on it. If required, fill with oil to the upper

level.

5. Place the oil dipstick in position and tighten

appropriately.

To change the oil:

NOTE:

Drain the used oil while the engine is warm.

Warm oil drains quickly and completely.

WARNING:

Take necessary protective measures

against hot oil to avoid any danger of burn.

1. Remove the oil filler cap.

2.

Place a suitable container next to the engine to

catch the used oil.

3. Tilt the engine on its right side. The used oil will

drain through the filler neck. Allow the oil to

drain completely.

NOTE:

Dispose used motor oil and the containers in

a manner that is compatible with the environment.

We suggest you take it in a sealed container to your

local recycling center or service station for recla

mation. Do not throw it in the trash, pour it on the

ground, or pour it down a drain.

4. Reposition the engine on a level position.

5. Fill the engine with the recommended oil.

6. Allow a couple of moments for the oil to settle

in the engine and then measure the oil level us

Frequency

ing the oil dipstick. Repeat steps number 5 and

6 until the oil level is correct.

7. Place the oil filler cap in position and tighten

appropriately.

WARNING:

Running the engine will low oil level will

cause engine damage.

NOTE:

If the engine frequently works under dusty

or other severe circumstances, change the engine oil

every 10 hours.

AIR FILTER

WARNING:

Operating the engine without an air

cleaner, or with a damaged air cleaner, will allow dirt

to enter the engine, causing rapid engine wear.

1. Remove the air filter cover (Fig. 7.2).

2. Make sure that the air filter (Fig. 7.1) is free

from dirt and in a good condition.

f

To clean a foam air filter element wash it with

home detergent and hot water and let it dry. Then

soak it in clean saturated engine oil and gently

squeeze out excess oil. If required, re place it with

a new one.

f

To clean a paper air filter element, clean light dirt

by gently taping it a few times on a hard surface

and replace if heavy dirt is present.

3. Clean the inside of the air filter case and cov-

er from dirt with a soft cloth. If the engine is

equipped with an oil bath type air filter, replace

the oil with new engine oil.

4. Reinstall the air filter element and follow the

reverse procedure to put back in position the

air filter cover.

NOTE:

If the engine frequently works under dusty

or other severe circumstances, clean the air filter el

ement every 10 hours. If necessary, change the air

filter element every 25 hours.

SPARK PLUG

To maintain the spark plug:

1. Remove the spark plug cap to access the spark

plug.

2. Use an appropriate spark plug tool to carefully

remove the spark plug.

3. Inspect the condition of the spark plug and

its electrode. It must be clean and not worn.

Check that the spark plug gap is between 0.7

and 0.8mm (Fig. 8). Replace the spark plug with

a new one, if needed.

4. Carefully thread the spark plug into the engine

by hand.

5. Once threaded, use the appropriate spark plug

tool to tighten the spark plug, paying atten

tion not to use excessive force damaging the

threads.

6. Re-attach the spark plug cap.

WARNING:

Never allow dirt or debris to enter the

cylinder bore. Before removing the spark plug, thor

oughly clean the spark plug and cylinder head area.

FUEL SEDIMENT CUP

WARNING:

Maintain the fuel carburetor only outdoors and in

well ventilated areas.

To maintain the fuel sediment cup:

1. Turn the fuel valve to the “OFF” position.

Summary of Contents for GVE 174 N1 PLUS

Page 3: ...3 www ffgroup tools com GVE 174 N1 PLUS GVE 200 N1 PRO GVE 200 N2 PRO 4 7 5 6 8 1 1 2 1 2...

Page 22: ...22 GVE 174 N1 PLUS GVE 200 N1 PRO GVE 200 N2 PRO f f f f f f f 26...

Page 62: ...62 GVE 174 N1 PLUS GVE 200 N1 PRO GVE 200 N2 PRO...

Page 63: ...63 www ffgroup tools com GVE 174 N1 PLUS GVE 200 N1 PRO GVE 200 N2 PRO...