| English

10

NOTE

According to the applicable product liability laws,

the manufacturer of the device does not assume lia

-

bility for damages to the product or damages caused

by the product that occurs due to:

f

Improper handling no complied with the operat

-

ing instructions.

f

Repairs by third parties and not by authorized ser

-

vice technicians.

f

Installation of non-original spare parts.

f

Non-intended use.

f

Electrical system breakdown due to power of the

machine in a manner not compliant with the elec

-

tric and VDE regulations.

TECHNICAL DATA

Article Number

46 424

Model

PWH 140 PLUS

Rated voltage

V

230/240

Rated frequency

Hz

50

Phase

Ph

1

Maximum operating pres

-

sure

bar

140

Maximum flow rate

l/h

450

Thermal capacity

kW

26

Outlet water temperature

°C

60

Absorbed power

kW

2,4

Motor poles

No

2

Motor working speed

rpm

2.800

Fuel tank capacity

l

4

Fuel consumption

kg/h

1,9

Detergent tank capacity

l

0,5

Discalling tank capacity

l

-

High pressure hose length

m

8

Power cable length

m

6

Sound pressure level (LpA)

dB(A)

82

Sound power level (LwA)

dB(A)

96

Uncertainty (K)

dB

2

Dimensions (LxWxH)

cm

64x48x76

Net weight

kg

47

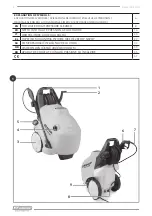

IDENTIFICATION (Fig 1)

1. Transport handle

2. Hose reel handle

3. Transport wheel

4.

On-Off switch

5. Fuel tank cap

6. High pressure lance

7. High pressure hose

8. Water outlet

9. Water inlet

OPERATION

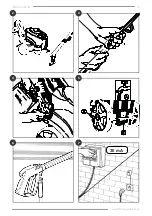

PREPARING THE UNIT

Unpacking and completing the assembly should

be done on a flat and stable surface, with enough

space for moving the machine and its packaging,

always making use of suitable equipment.

All the fundamental parts and safety devices of

the machine are assembled by the manufacturer.

For reasons of packing and transport, some sec

-

ondary parts are supplied separately. The user

must fit these parts as explained in the instruc

-

tions supplied in each assembly kit (Fig. 2, 3).

FUELING AND LUBRICATION

In the hot water high pressure cleaners a diesel

fuel burner is used for water heating.

Fuel specifications: Diesel for motors.

WARNING

Never smoke whilst refueling and keep fuel away

from all sources of fire or spark. Avoid inhaling the

fuel fumes and always refuel in outside and well ven

-

tilated areas.

To fill the fuel tank (Fig. 4):

1.

Remove the fuel tank cap (Fig. 1.5).

WARNING

Carefully open the tank top as pressure could

have formed inside.

2.

Add fuel to the upper level of the fuel tank.

Leave a minimum 5mm of space between the

top of the fuel and the inside edge of the tank

to allow for expansion.

3.

Reposition the fuel tank cap and tighten appro

-

priately.

WARNING

Attempting to use the cleaner without fuel may

cause damage to the fuel pump.

SAFETY DEVICES

The safety devices protect the user and the appli

-

ance. The machine is factory set and all its safety

devices are sealed. It is forbidden to alter their ad

-

justment values. They must not be tampered with

or used for other than their designated purpose.

Safety valve to protect the high pressure hy

-

draulic circuit in the event of a by-pass valve mal

-

function or if the hydraulic circuit is blocked. The

safety valve is calibrated by the manufacturer and

sealed. Operations involving the safety valve must

be performed by a technical service center only.

Safety device on lance handgrip to prevents the

trigger on the handgrip from being operated ac

-

cidentally.

PWH 140 PLUS

Summary of Contents for PWH 140 PLUS

Page 4: ...4 8 10 9 11 PWH 140 PLUS...

Page 5: ...5 www ffgroup tools com 5 12 13 14 15 PWH 140 PLUS...

Page 27: ...27 www ffgroup tools com CO 0 04 nr 2 Shell Bacharach f PWH 140 PLUS...

Page 28: ...28 f f f IEC 60364 1 3kW IEC 60364 1 3mm 3 kW 30mA 30ms PWH 140 PLUS...

Page 32: ...32 50 100 200 300 500 1 2 3 4 5 14 15 1 2 PWH 140 PLUS...