14

ENGLISH

ENGLISH

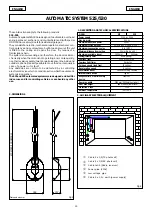

AUTOMATIC SYSTEM 525/530

These instructions apply to the following models:

525 - 530

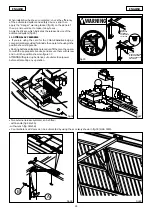

Automatic systems 525-530 are designed to automate overhead

spring-balanced, sectional, and counterbalanced (with special

GDA 3000 accessory) doors for residential garages.

They consist of an electro-mechanical operator, electronic con-

trol appliance and courtesy lamp built into a single unit. The unit

is fitted to the ceiling and opens the door by means of a

transmission chain.

The system is non-reversing and, therefore, the door locks me-

chanically when the motor is not operating and, consequently,

no other lock is necessary; two manual releases on the inside and

outside (optional) make it possible to move the door manually in

case of a power cut or fault.

Any obstacles are certain to be detected by a controlling

electronic device which comes into action while the automatic

system is in operation.

The 525 and 530 automated systems were designed and built for

indoor use and for controlling vehicle access.Avoid any other

use.

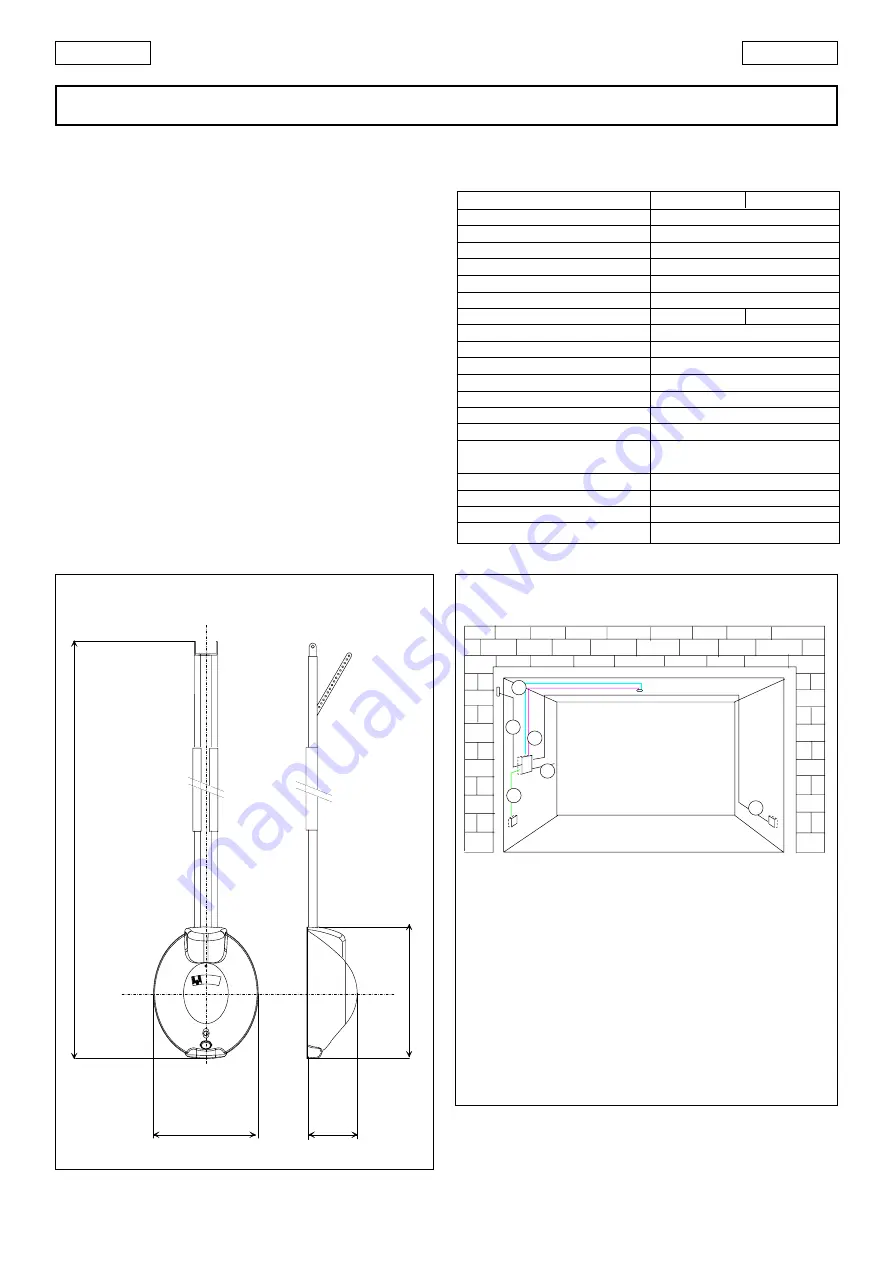

2. DIMENSIONS

Fig.1

Fig.2

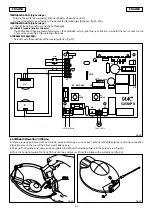

Power pipe (230V)

Cable 4 x 0,5 (RX photocell)

Cable 3x0.5 (Radio receiver)

Cable 2 x 0,5 (TX photocell)

Low voltage pipe

Cable 2 x 1.5 + earth (power supply)

3. ANCILLARY ELECTRICAL EQUIPMENT

1. DESCRIPTION AND TECHNICAL SPECIFICATIONS

328

157

415

2738 (525)/ 3338 (530)

Dimensions in mm

1

2

3

4

5

6

MODEL

525 530

Power supply

230V ac 50Hz

Electric motor

24V dc

Maximum absorbed power

220W

Maximum cycles per hour

20 (with load of 28Kg at 20°C)

Maximum consecutive cycles

6 (at 20°C)

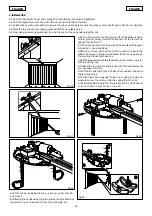

Minimum distance from ceiling

35mm (Fig.4 and 5 )

Maximum available travel

1900mm

2500mm

Pulling/thrust power

600N (~60Kg)

Courtesy light

230V ac 40W max

Courtesy light timer

2 minutes

Carriage speed (load free)

12 cm/sec.

Deceleration speed

6 cm/sec.

Deceleration travel

Varies according to setup

Internal safety device

Type 2

Response time of built-in safety

150msec

device

Door max width

3000 mm (5000mm sectional)

Door max height

See max available travel

Protection class

IP20

Ambient temperature

-20 / +55°C