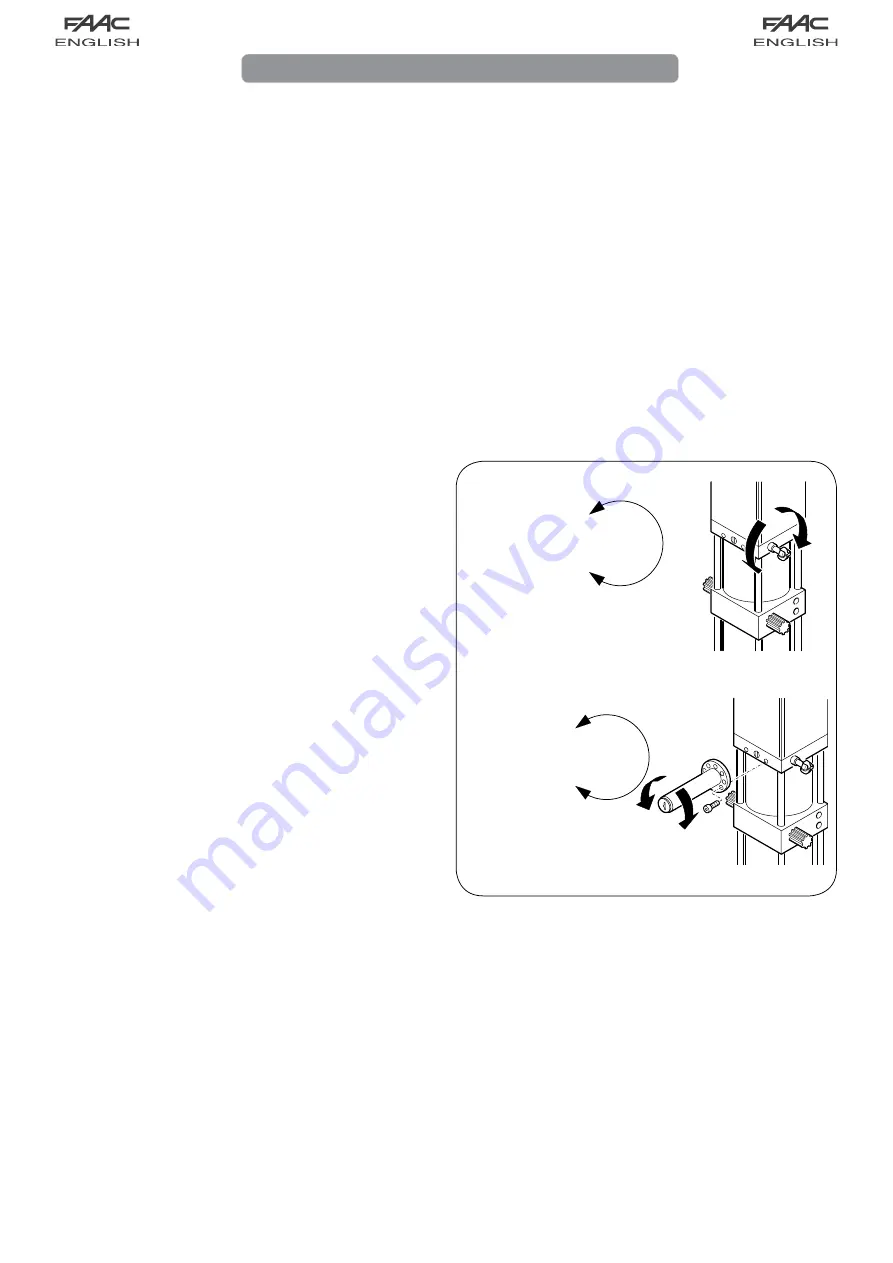

SBLOCCA/UNLOCK

DESBLOQUEAR

DEBLOQUE/ENTRIEGELT

BLOCCA/LOCK

BLOQUEAR

BLOQUE/VERRIEGELT

SBLOCCA/UNLOCK

DESBLOQUEAR

DEBLOQUE/ENTRIEGELT

BLOCCA/LOCK

BLOQUEAR

BLOQUE/VERRIEGELT

User’s guide

The automated systems may have safety devices (photocells)

which prevent the door from reclosing when an obstacle is

located in the area protected by them.

The 595 I/S automated system is fitted as standard with an

anti-crushing safety device that limits the torque transmitted to

the door.

The hydraulic system assures door locking in any position.

The door can be opened manually only after operating the

unlocking device.

MANUAL OPERATION

If the door must be operated manually because of a power

failure or malfunction, use the unlocking device as follows.

Lever release device (see Fig. 1)

External key release device (see Fig.2):

- Insert the key in the lock, and turn

the key

anticlockwise

by 1

turn.

GENERAL SAFETY REGULATIONS

If correctly installed and operated, the 595 I/S automated system

ensures a high level of safety.

However, some simple rules should be followed to avoid

accidents:

- Do not pass underneath the door while it is moving: wait until it

is completely raised.

- Do not remain stationary under the door.

- Do not stand in the vicinity of the automated system or allow

anyone else, especially children, to do so, and do not place

objects in the vicinity of the automated system. This is particularly

important during operation.

- Keep radio controls or any other pulse generator out of the

reach of children, to prevent them from accidentally operating

the automated system.

- Do not allow children to play with the automated system.

- Do not deliberately obstruct the movement of the door.

- Do not attempt to operate the door manually without first

unlocking it.

- In the event of a malfunction, unlock the door to allow access

and call a qualified technician for service.

- After manual operation, disconnect the electrical power supply

from the system before returning to normal operation.

- Do not make any modifications to components belonging to

the automated system.

- Do not attempt to perform any repair work or tamper with the

automated system. Call qualified personnel for repairs.

- At least once every six months, have the automated system,

the safety devices and the earth connection checked by a

qualified technician.

DESCRIPTION

The 595 I/S automated system is an operator for counterbalanced

up-and-over doors. It is ideal for controlling vehicle access areas

up to 5 metres wide (application with double operator) and with

medium transit frequencies.

Door operation is controlled by an electronic control unit mounted

in an enclosure which assures adequate protection against

atmospheric agents and can be fitted inside the garage.

The normal position of the door is closed in a vertical position.

When the electronic control unit receives an opening command

from the radio control or any other pulse generator, it activates

the hydraulic system and causes the door to rotate upwards by

90° to the horizontal position, thereby allowing access.

If automatic operation has been selected, the door closes

automatically after the selected pause time.

If semiautomatic operation has been selected, a second impulse

must be sent to close the door.

An open command given while the door is closing causes the

door to reverse direction of movement.

A stop command (if available) stops movement at any time.

For detailed information on door operation in the various

operating modes, contact the installation technician.

- Manually open or close the door.

RETURNING TO NORMAL OPERATION

To prevent an accidental impulse from activating the door during

this operation, before you restore normal operation, disconnect

the system from the power supply.

Lever release device (see Fig. 1).

External key release device (see Fig.2):

- turn the key

clockwise

until it stops.

- turn the key

anticlockwise

very slowly to the point where it can

be extracted.

595 I/S AUTOMATED SYSTEM

Fig. 1

Fig. 2

Summary of Contents for 595

Page 1: ...595...