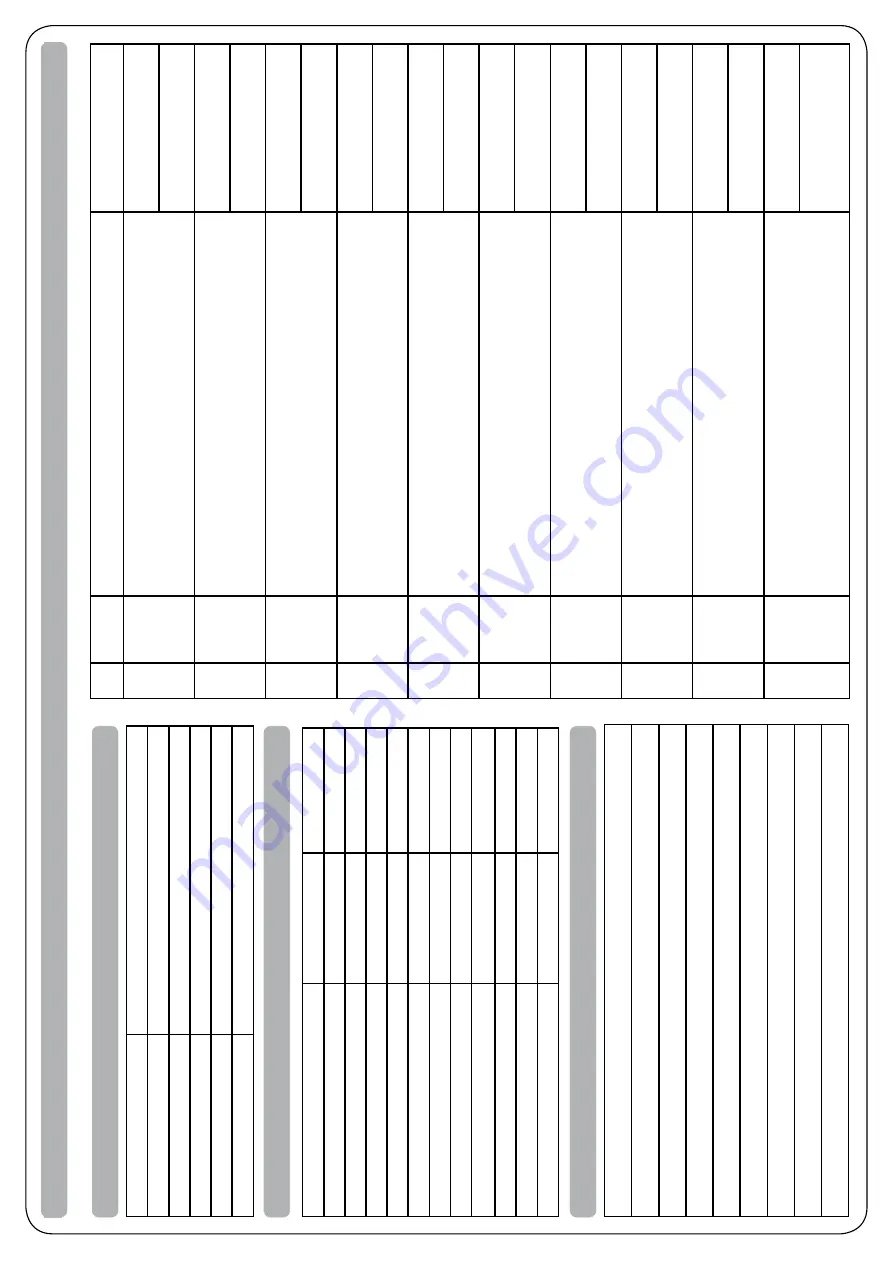

REGISTRO DI MANUTENZIONE

No

.

Date

Job description

Signatures

1

Technician

Customer

2

Technician

Customer

3

Technician

Customer

4

Technician

Customer

5

Technician

Customer

6

Technician

Customer

7

Technician

Customer

8

Technician

Customer

9

Technician

Customer

10

Technician

Customer

Installer

Customer

Type of system

Serial No.

Installation date

Start-up

PART

MODEL

SERIAL NUMBER

Operator

Safety device 1

Safety device 2

Pair of photocells 1

Pair of photocells 2

Control device 1

Control device 2

Radio control

Flashing lamp

System data

System configuration

Indication of residual risks and of foreseeable improper use

MAINTENANCE REGISTER

Summary of Contents for 595

Page 1: ...595...