3

10

20

30

40

50

60

70

80

90

100

0

1

2

3

4

5

6

7

8

9

10

10 11 12

Percentuale

di lav. %

Tiempo (h)

% Duty cycle

% Fréquence

d'utilisation

% Benutzungs-

frequenz

% Frecuencia

de utilización

Zeit (Std.)

Temps (h)

Time (h)

Tempo (h)

ENGLISH

595 I/S AUTOMATED SYSTEM

DESCRIPTION AND TECHNICAL CHARACTERISTICS

. MAXIMUM USE CURVE

The 595 I/S automated system is a hydraulic unit formed of a

motor pump and a piston-rack assembly, which ensures optimal

automation of up-and-over garage doors for residential and

condo applications.

It is mounted on the door by means of

accessories.

The system has an adjustable anti-crushing safety system, a

device that stops and locks the door in any position, and a

convenient manual release device to be used in the event of a

power failure or malfunction.

The 595 I/S automated system has been designed and

manufactured for the automation of counterbalanced up-and-over

doors. Figures A, B and C page 4 show the most commonly

used types of up-and-over doors. No other use of the system is

allowed.

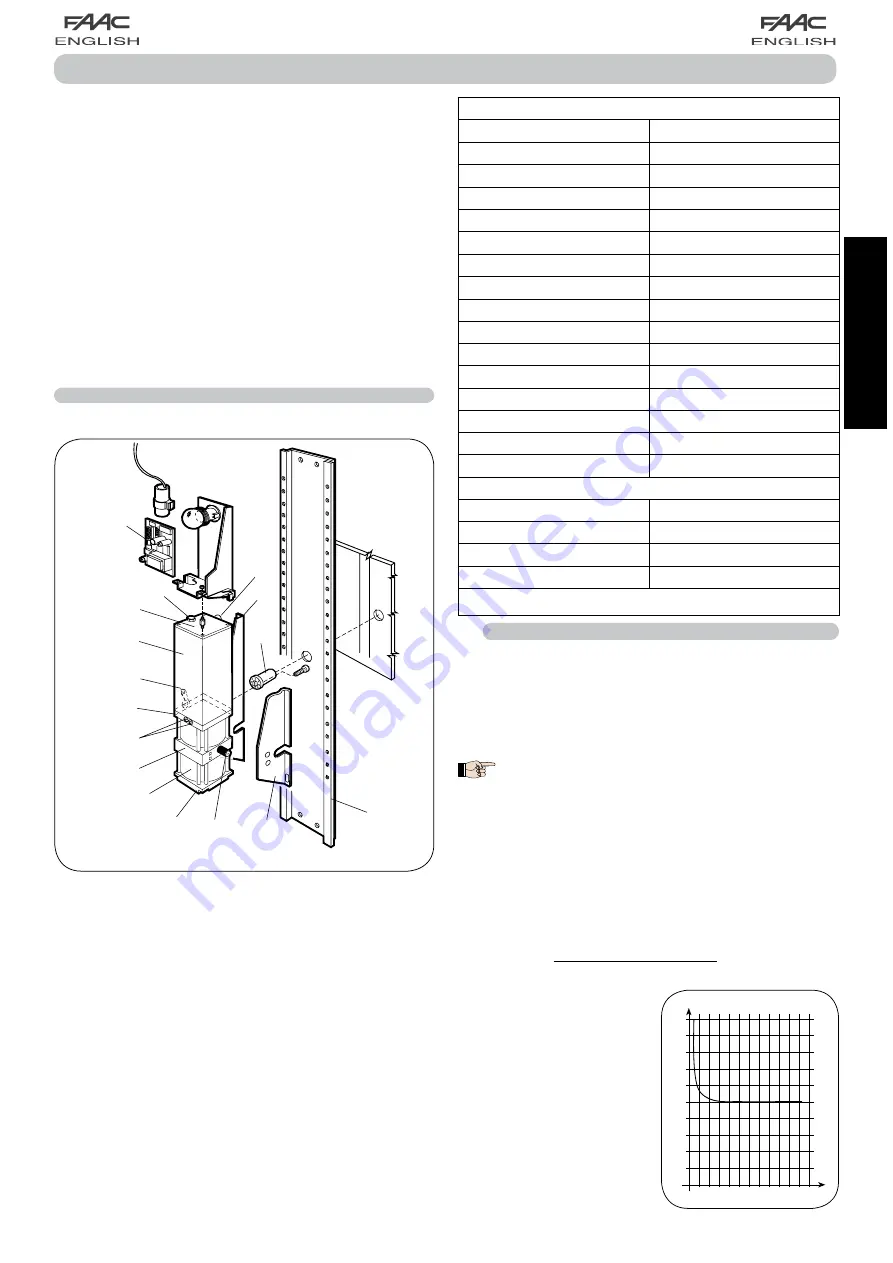

1

2

4

3

5

6

7

8

9

10

11 12

13

14

15

16

a

external release device (optional)

b

side support for operator fastening

c

upper flange

d

oil filler plug

e

oil tank

f

internal release knob

g

distribution flange

h

torque adjustment screws

i

central body for operator fastening

j

cylinder

k

lower flange

l

drive shaft

m

side support for operator fastening

n

backplate

o

bleed screw

p

596 MPS control unit

Fig. 1

Table 1

Technical specifications of 595 I operator

Power supply

230V

~

(+6 -10 %) 50Hz

Absorbed power (W)

220

Duty cycle %

50

Oil type

FAAC HP OIL

Oil quantity (l)

1

Motor winding thermal cutout

120°

Anti-crushing system

bypass valves fitted as std

Operating ambient temperature

-20 ÷ +55 °C

Protection class

IP 31

Weight (Kg)

10

Pump flow rate (l/min.)

0.75

Angular velocity (rpm)

1.54

Max. door weight (Kg/m

2

)

15

Max torque (Nm)

400

Max. door height (m)

2.70

with 1 operator

Max. door width (m)

3.5

with 1 operator

Technical characteristics of electric motor

Speed (rpm)

1400

Power (W)

200

Current drawn (A)

1.2

Power supply

230V~ (+6 -10 %) 50Hz

The curve allows the maximum working time (T) to be obtained

as a function of the use frequency (F).

For example, the 595 I/S operators can operate uninterruptedly

at an use frequency of 50%.

To ensure good operation, keep to the field of operation lying

below the curve.

IMPORTANT: THE CURVE IS OBTAINED AT A TEMPERATURE

OF 24 °C.

EXPOSURE TO DIRECT SUN RAYS MAY REDUCE USE FREQUENCY

DOWN TO 20%.

Calculating use frequency

The use frequency is the percentage of effective working time

(o closing) with respect to the total cycle time (opening

+ c pause times).

It is calculated using the following formula:

where:

Ta = opening time

Tc = closing time

Tp = pause time

Ti = interval between

one complete cycle

and the next.

Ta + Tc

%F =

X 100

Ta + Tc + Tp + Ti

Summary of Contents for 595

Page 1: ...595...