4

10

c

m

A

B

S

ENGLISH

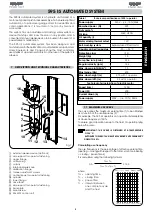

2 INSTALLATION LAYOUT

a

junction box

b

T15MP pushbutton

c

FAAC 595 I operator

d

Rx photocell

e

plus radio receiver

f

T10 key-operated pushbutton

g

Tx photocell

Fig. 2

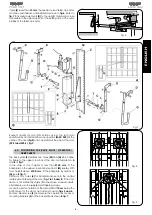

3 DIMENSIONS

Fig. 3

4 INSTALLATION

4. PRELIMINARY CHECKS

Make sure that the dimensions of the door are within the limits

stated in the technical specifications. Make sure that the door

operates smoothly. If necessary, clean the tracks and lubricate

them with a silicon based lubricant. Do not use grease. Check the

condition of all door bearings and joints. Remove the mechanical

door locks so that when the door is closed it will be locked only

by the automated system. Make sure that there is a

230 Vac

power supply point in the garage, and that it is protected by an

adequate residual current circuit-breaker.

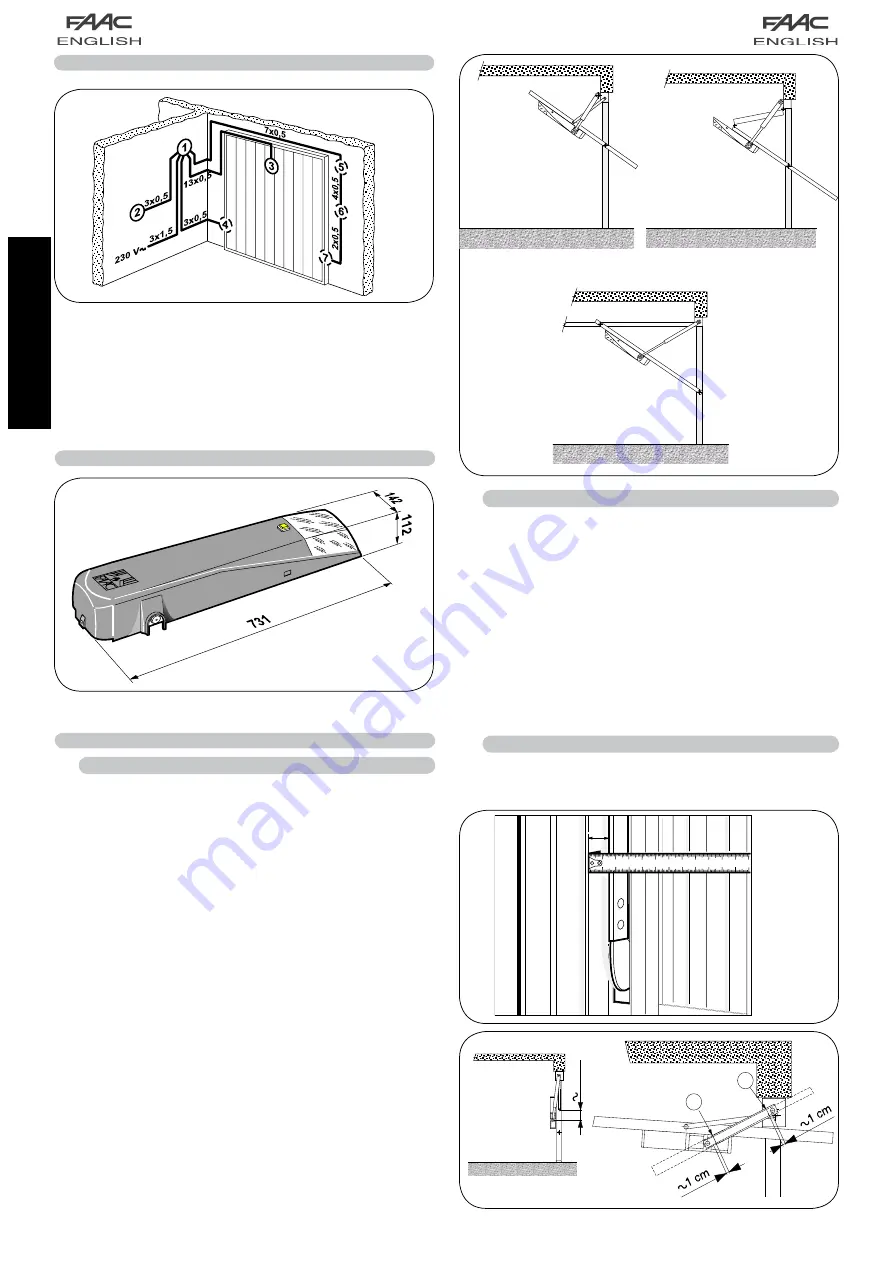

The

FAAC 595 I

operator is designed to operate various types

of up-and-over doors with counterweights.

Figs. A

,

B

, and

C

show the most common types: projecting single panel,

projecting articulated panel, non-projecting single panel with

horizontal tracks. Either metal blocks or bricks can be used as

counterweights, though some door manufacturers use springs

instead of weights. Check in any case that the door pivots

correctly when opening and closing.

Fig.B

Fig.C

Fig.A

4.2 INSTALLATION OF OPERATOR

Accessories of the

FAAC 595 I/S

operators are supplied in two

versions:

Welded assembly

- welded telescopic arms, drive shafts, and mounting brackets.

Screw assembly

- all accessories feature screw-on attachment.

Straight or curved telescopic arms are available for both

versions.

The present instructions refer to screw assembly.

4.3. POSITIONING OF TELESCOPIC ARMS

Ensure that there is a gap

(S) fig.4

of at least

15 mm

between

the existing cross bar and the frame. This is essential if straight

telescopic arms are to rotate correctly as shown in

fig. 5

.

Fig. 4

Fig. 5

Summary of Contents for 595

Page 1: ...595...