6

- 5°

T

L

ENGLISH

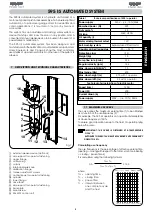

Disconnect the operator and open the garage door as indicated

in

fig.10

and turn the pinion in the direction of the arrow to the

piston limit. Rotate though approx.

5°

in the opposite direction.

Close the door and fit drive shafts

(T) fig.7

over the operator

pinions and cut to size as shown in

figs. 8/9

. Fit bushings

(C)

and

brackets

(L)

fig. 7

on the drive shafts and secure brackets

(L)

on

the door reinforcement ribbing taking care to maintain correct

alignment of the drive shafts.

Fig. 10

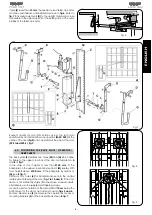

Straight arm

: refer to

fig. 5

.

Curved arm

: refer to

fig. 6.

Open the garage door and position the telescopic arm as

indicated in

figs. 5 or 6

. Cut the

outer profile

at point

A

. Cut the

inner profile

of the telescopic arm at reference point

B

.

N.B.

Leave a gap of about 1 cm at the ends of both profiles.

Insert the drive shafts

(T)

in the inner profile of the telescopic arm

(Q) fig.7,

already cut to size, and drill an 8 mm hole. Secure by

means of an MA8 bolt.

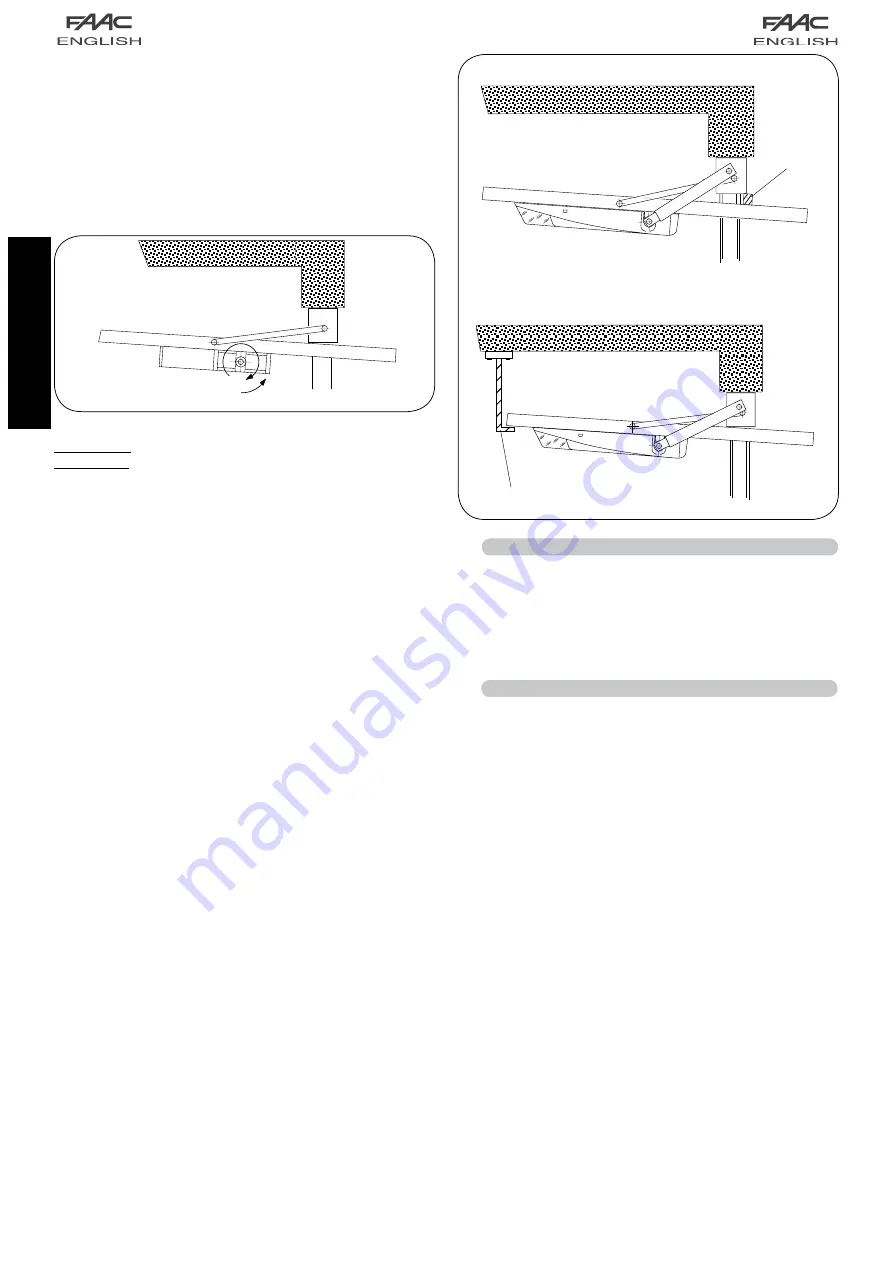

To ensure smooth door closing operation install a cushion pad

(T) fig.11.

Alternatively, to prevent garage door off-balance and

ensure optimal operator functioning, construct and install an

L

bracket as shown in

fig.12

.

Fig. 12

Fig. 11

4.5. ADJUSTING THE COUNTERWEIGHTS

The weight of the counterweights must be increased to ensure

smooth operation. If there is insufficient space to add to the

existing counterweights, remove them and replace them with

blocks of a higher specific weight. Release the operator and

move the door to half-open position (45°). The door should

remain in balance.

4.6. DOUBLE APPLICATION

For up-and-over doors 3.50 to 5 m wide, one 595 I (integrated)

operator and one 595 S (slave) operator must be used. The

maximum permitted height is 3 m. Install in the same way

as for a single motor

(fig. 9)

. The electrical connection of

the SLAVE drive unit must be made on the control unit of the

MASTER operator. Connect the power cables of the SLAVE operator

in parallel with those of the MASTER, taking care to respect the

assignments and rotation direction.

Add the one supplied with the SLAVE operator in parallel with the

existing thrust capacitor.

Summary of Contents for 595

Page 1: ...595...