6

Version 07/11 - Page 5

9.0 feet

10.0 feet

0.0 feet

19.0 feet

TOOLS NEEDED FOR INSTALLATION

• Saber Saw or Jig Saw

• Drill

• 1 1/4" Wood Drill Bit

• Pliers

• Phillips Screwdriver

• Wire Stripper or Utility Knife

• Metal Snips

• Measuring Tape or Ruler

• Level

• Pencil

• Caulking Gun

• Duct Tape

PARTS SUPPLIED FOR INSTALLATION

• 1 Backdraft Damper

• 1 Vent Grate (for recirculating installations only)

• 1 Rear Trim Strip (for back of the hood)

• 1 Literature Package

PARTS NEEDED FOR INSTALLATION

• 2 Conduit Connectors

• Power Supply Cable

• 1 Wall or Roof Cap

• All Metal Ductwork

OPTIONAL ACCESSORIES AVAILABLE

• Charcoal Filters

For non-vented installations only,

replace charcoal filters as needed

part #

FILTER1

PLAN THE DUCTWORK

The Cristal 24" slideout rangehood is designed to offer wide flexibility of installations.

The rangehood can be ducted vertically through a 6" round vent. The unit can also

be installed in a recirculating configuration. The unit comes standard in the top

venting position.

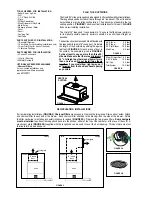

FIGURES 1

shows vertical installations for this unit.

FIGURE

2

shows recirculating installation.

The Cristal 24" requires 6" round ductwork. To ensure that the blower performs

to its highest possible capacity, ductwork should be as short and straight as

possilbe.

RECIRCULATING INSTALLATIONS

For recirculating installations

(FIGURE 2)

,

Charcoal Filters

are necessary. Remove the two grease filters and set aside. Attach

one charcoal filter to each end of the blower. Each charcoal filter attaches to the black grid on the side of the blower. Rotate

the filter clockwise to install and counterclockwise to remove

(FIGURE 2A)

. Replace the two grease filters.

Some ductwork

must be installed

to exhaust the rangehood back into the kitchen, either at the top of the cabinet or at the face of the soffit. A

plastic vent grate

(FIGURE 2B)

supplied with the rangehood can be used to cover the duct opening. This duct work must not

terminate into a dead air space.

FIGURE 2A

45˚ Elbow

90˚ Elbow

90˚ Flat Elbow

Wall Cap

FIGURE A

9 Feet Straight Duct

2 - 90˚ Elbows

Wall Cap

Total System

FIGURE B

3.0 feet

5.0 feet

12.0 feet

0.0 feet

VERTICAL

DUCTING

FIGURE 1

cabinet

ceiling

6” round

duct

hood

cabinet

ceiling

6” round

duct

hood

soffit

vent grate

vent grate

FIGURE 2B

FIGURE 2

The ductrun should not exceed 35 feet if ducted with

the required minimum of 6" round duct. Calculate

the length of the ductwork by adding the equiva-

lent feet in

FIGURE A

for each piece of duct in

the system An example is given in

FIGURE B

.

For best results, use no more than three 90°

elbows. Make sure that there is a minimum of

24" of straight duct between elbows if more

than one is used. Do not install two elbows

together. If you must elbow right away, do it

as far away from the hood's exhaust opening

as possible.

EN

1

2

12

CARE

Grease filters

CLEANING METAL SELF- SUPPORTING GREASE FILTERS

• The filters must be cleaned every 2 months of operation, or

more frequently for particularly heavy usage, and can be

washed in a dishwasher.

• Remove the filters one at a time by pushing them towards the

back of the group and pulling up at the same time.

• Wash the filters, taking care not to bend them. Allow them to

dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

Activated charcoal filter (Recirculating version)

These filters (not supplied with the rangehood)are not washable

and cannot be regenerated, and must be replaced approximately

every 4 months of operation, or more frequently with heavy us-

age.

REPLACING THE ACTIVATED CHARCOAL FILTER

• Remove the metal grease filters

• Remove the saturated activated charcoal filter as shown (

A

).

• Fit the new filters (

B

).z

• Replace the metal grease filters.

�

�

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the 2 screws fixing the Lighting support, and pull it

out of from the Hood.

• Extract the lamp from the Support.

• Replace with another of the same type, making sure that the

two pins are properly inserted in the lamp holder socket holes.

• Replace the Support, fixing it in place with the two screws re-

moved as above.

Summary of Contents for Cristal 24 SS

Page 35: ...35...