17 <

<

<

<

L

14

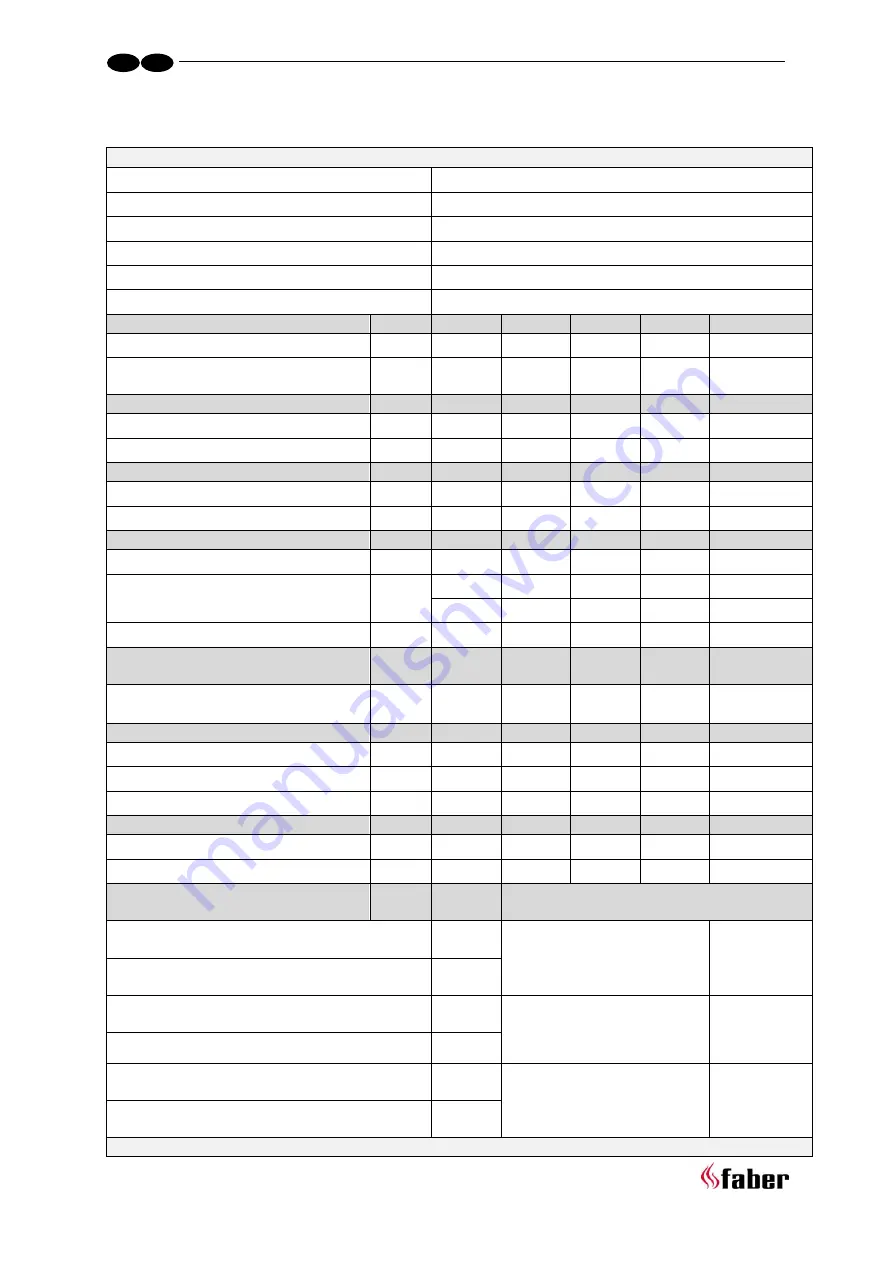

Technical data

Technical data

Type indication(s)

Farum, Fyn, Fyn 450, Concept I-450

Type appliance

C11/C31/C91

Diameter outlet/inlet

100/150

Gas connection

3/8"

Indirect heating functionality

no

Category

II2H3+

Symbol

Unit

Reference gas/inlet pressure

G20-20

G30-30

G31-37

mbar

Emissions in space heating

NOx

78

88

85

mg/kWh

input

(GVC)

Direct heating output

Nominal heat output

P

nom

4,2

3,9

3,9

kW

Minimum heat output (indicative)

P

min

1,5

1,4

1,4

kW

Useful efficiency (NCV)

At nominal heat output

ꞃ

th,nom

93,7

93,7

93,7

%

At minimum heat output (indicative)

ꞃ

th,min

89,7

89,7

89,7

%

Appliance input data

Input

Hi

4,5

4,2

4,2

kW

Gas rate at full mark

0,482

0,127

0,164

m³/h

320

310

kg/h

Burner pressure at full mark

10

24,8

31,6

mbar

Power requirement for permanent pilot

light

Power requirement for permanent pilot

light (if applicable)

P

pilot

0,11

0,11

0,11

kW

Additional electricity consumption

At nominal heat output

el

max

0

0

0

kW

At minimum heat output

el

min

0

0

0

kW

In standby mode

el

SB

0

0

0

kW

Energy-efficiency

Energy-efficiency class

A

A

A

Energy-efficiency index

EEI

88

88

88

Type heating output/control room

temperature

Other control options

One step heat output, no control of room

temperature

no

Control of room temperature,

with presence detection

no

Two or more manually adjustable stages, no

control of room temperature

no

With mechanical control of the room temperature

by thermostat

no

Control of room temperature,

with open window detection

no

With electronic control of the room temperature

no

With electronic control of the room temperature

plus day-time switch

yes

With optional remote control

yes

With electronic control of the room temperature

plus week-time switch

no

Glen Dimplex Benelux Saturnus 8 Heerenveen The Netherlands

Summary of Contents for Fyn 450

Page 1: ...Fyn 450 40010929 1840 Fyn 450 ENG ...

Page 2: ...1 L 1 1 1 2 1 3 1 4 1 5 1 6 2 1 2 2 2 3 ...

Page 3: ...2 L 3 1 3 2 4 0 4 1 4 2 4 3 4 4 ...

Page 15: ...14 L 12 Examples flue materials Fig 12 1 Fig 12 2 Fig 12 3 ...

Page 21: ...20 L 16Troubleshooting guide ...

Page 22: ...21 L YES ...

Page 23: ...22 L YES YES ...

Page 24: ...23 L ...

Page 25: ...24 L ...

Page 26: ...25 L 17Dimensional drawings 17 1 Fyn 450 ...

Page 27: ...26 L 17 2 Ventilation grid ...

Page 28: ...27 L 17 3 Remote access door ...

Page 29: ...28 L ...

Page 30: ...29 L ...

Page 31: ...Fyn 450 ...