EN

8

8

INSTALLATION

Wall drilling and bracket fixing

• Draw a vertical line on the wall on the right or on the left side depending on the hood model,

at 200 mm (90 cm hood version) or at 350 mm (120 mm hood version) taking as a reference

point the centre of the hob. Start the line from the ceiling or from other upper limit and

finish it at the 650 mm distance from the hob. This line is needed when aligning the

brackets.

• Place the

7.2.1

bracket, as indicated, at 1-2 mm from the ceiling or from other upper limit

aligning its central point on the vertical reference line.

• Draw the central points of the bracket holes.

• Place the

7.2.1

bracket, as indicated, at X mm under the first bracket (X= upper chimney

height) aligning its central point on the vertical reference line.

• Draw the central points of the bracket holes.

• Draw the reference point, as indicated, at 116 mm from the vertical reference point and at

970 mm above the hob.

• Repeat the same procedure on the opposite side.

• Draw the reference point, as indicated, at Z mm (Z= see the table) from the vertical

reference point and at 690 mm above the hob.

• Drill ø 8 mm the marked points.

• Insert the

11

plugs into the holes.

• Fix the brackets using the

12a

screws (4,2 x 44,4 ) supplied with the hood.

• Screw the 2

12a

screws

(4,2 x 44,4), supplied with the hood, in the hood body fixing holes.

It is necessary to leave a 5-6 mm gap between the wall and the screw head.

Cappa

Y

Z

90 cm

200

565

120 cm

350

830

7.2.1

970

X

1÷2

Y

116

650 min.

116

Y

11

12a

690

Z

Summary of Contents for STILO DX/SP A90

Page 1: ...Instruction Manual...

Page 14: ...RU 1 4 14 650 I 120 0 04 2...

Page 15: ...RU 1 5 15 3 8...

Page 16: ...RU 1 6 16 2 4...

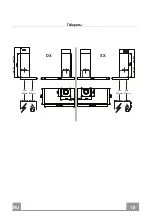

Page 18: ...RU 1 8 18 SX DX min 730 max 1000 min 730 max 1000 Min 500mm Min 650mm Min 500mm Min 650mm...

Page 21: ...RU 2 1 21 3 7 2 1 4 12c 2 9 x 9 5 2 12c 2 9 x 9 5 2 1 2 2 7 2 1 12c 12c...

Page 22: ...RU 2 2 22 T2 T1 L T3 T1 T2 T3 L T1...

Page 23: ...RU 2 3 23 2 4...

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ...436005061_ver3...