INSTRUCTIONS F330

19

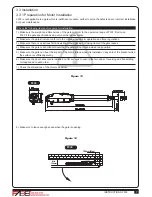

4.1.4 Photocells Adjustment (Dip 7.Photo)

4.1.5 Flashing Light Adjustment (Dip 8.Light)

4.2.1 Electric Latch Adjustment (Dip 5.Latch)

4.2.2 Slowdown Speed Adjustment of The Gear Motors (Dip 6.Slow)

4.2.3 Operation Speed Adjustment of The Gear Motors (Dip 7.Fast)

4.2.4 Single and Dual Gate Operation Adjustment (Dip 8.Ds/Set)

4.2 SW2 Dip Switch Setting

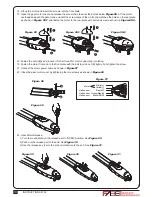

4.1.3 Gate Auto-close Adjustment (Dip 4.Auto 3, Dip 5.Auto 2 & Dip 6.Auto 1)

Dip switch 6 OFF

Dip switch 6 ON

Dip switch 6 OFF

Dip switch 6 ON

Dip switch 6 OFF

Dip switch 6 ON

Dip switch 6 OFF

Dip switch 6 ON

Dip Switch 5 OFF

Dip Switch 5 OFF

Dip Switch 5 ON

Dip Switch 5 ON

Dip Switch 5 OFF

Dip Switch 5 OFF

Dip Switch 5 ON

Dip Switch 5 ON

Dip Switch 4 OFF

Dip Switch 4 OFF

Dip Switch 4 OFF

Dip Switch 4 OFF

Dip Switch 4 ON

Dip Switch 4 ON

Dip Switch 4 ON

Dip Switch 4 ON

No auto-close

3 sec.

10 sec.

20 sec.

40 sec.

60 sec.

120 sec.

300 sec.

Auto-close 1

Auto-close 2

Auto-close 3 Effect

ON: When encountering any obstacles, the gates will stop during opening phase ; stop and reverse during closing phase.

OFF: The gate will keep moving when encountering any obstacles during closing and opening phases.

ON: The flashing light blinks for 3 seconds before the gate moves, and blinks simultaneously during the movement.

OFF: The flashing light blinks and the gate moves simultaneously.

ON: The electric latch functions when dip switch is set to “ON”.

OFF: The electric latch does not function when dip switch is set to “OFF”.

ON: The speed is 70% output of the full speed.

OFF: The speed is 50% output of the full speed.

ON: The speed is 100% output of the full speed.

OFF: The speed is 80% output of the full speed.

ON: Dual Gates operation in system learning and normal operation.

OFF: Single Gate operation in system learning and normal operation.

Note: Auto-close mode activates when the gates move to the end position or stopped manually. If the transmitter,

push button, or the key selector is activated before the auto-close counting, the gate will close immediately.

Summary of Contents for F330

Page 2: ......

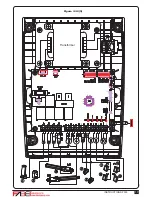

Page 19: ...INSTRUCTIONS F330 17 Transformer Figure 3 3 8 5 12V 12V 12V ...

Page 28: ......