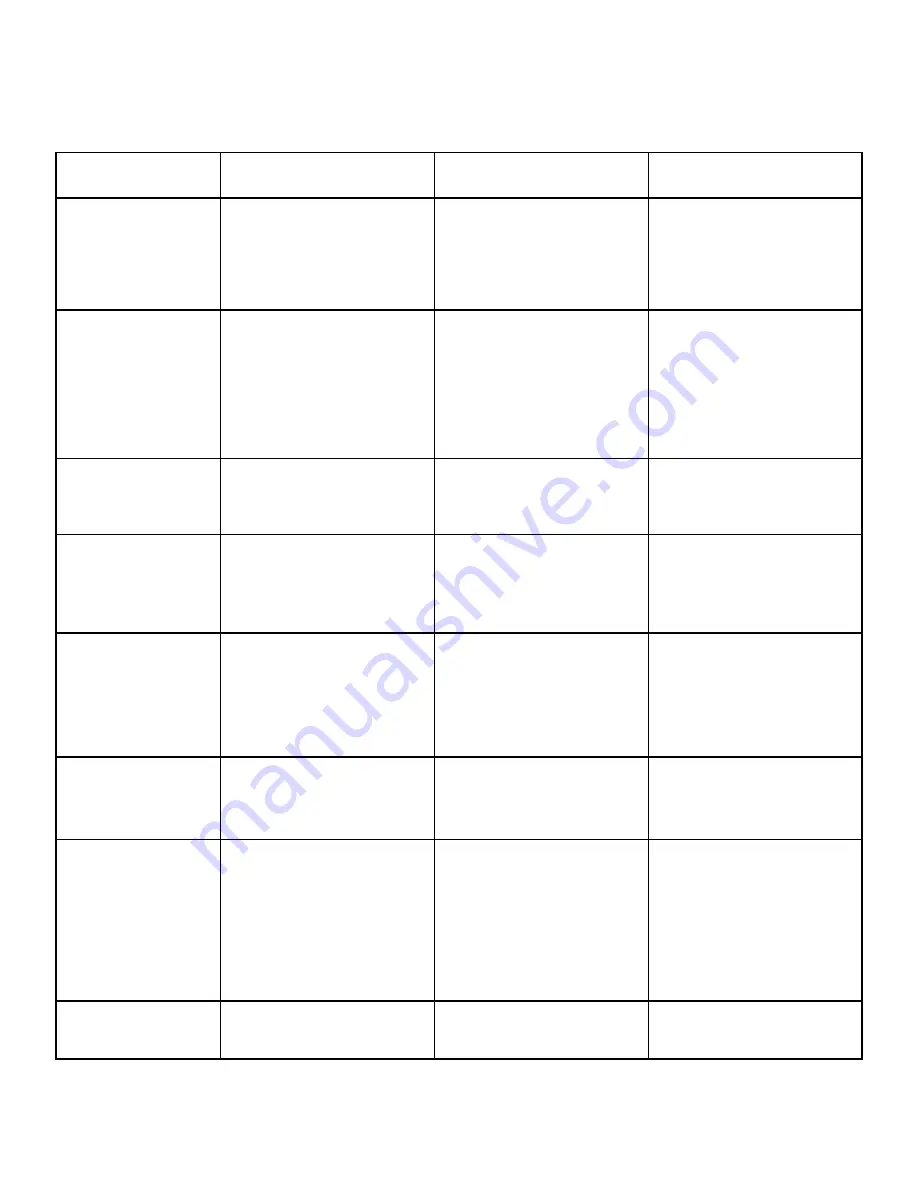

Fablicator Standard Materials

ABS

PLA

PETG

Material

A Mixture of Acrylonitrile,

Polybutadiene, and Polysty-

rene.

Starch based, Biodegradea-

ble plastic

A type of Polyester Resin

What is it?

Higher temperature toler-

ance, slightly more elastic

than PLA. Most easily

drilled, tapped, sanded and

painted.

High strength and least

warping, cracking, and de-

lamination when printing.

Strong and impact resistant

material. Low warping,

cracking, and delamination.

High wear resistance.

What are it’s main

benefits?

95C

60C

60C

Maximum Structural

Temperatures

260C Head

125C Bed

240C Head

75C Bed

240C Head

75C Bed

Typical Printing Tem-

perature

Opaque

Most colors opaque or very

slightly translucent

Most colors semi-

translucent

Optical Properties

Legos, Pipe, Toys

Small food containers, Bio-

degradable cups, Utensils

Water Bottles, Food Pack-

aging

Common real world

uses

What are the diffi-

culties printing this

material?

Large parts may lift off

platform (warp,) crack, or

delaminate easily

Small cross section parts

may deform if not enough

time between layers

Small cross section parts

may deform if not enough

time between layers. Oc-

casional problems with ad-

hesion to build platform.

Density

1.04g/cc

1.2g/cc

1.38g/cc