19

Extruder Problems

1.

If filament is not exiting the extruder while printing or

manually extruding, you likely have a problem with the

extruder.

If the filament extrudes fine in air, but makes a clicking

sound when printing the first layer of a part, it is most likely

a bed leveling issue instead.

See the section on bed leveling

and calibration

2.

First, check that the nozzle is heating up. Set the

temperature within the Fablicator interface to 240

and see if it rises from room temperature.

If no change is seen on-screen, physically check to

see if the heater block is getting hot. Pressing a

piece of filament onto the side of the block is a good

way to tell.

3.

If the heater block is hot, but the software says it’s

cold, the PT100 temperature sensor is likely to

blame.

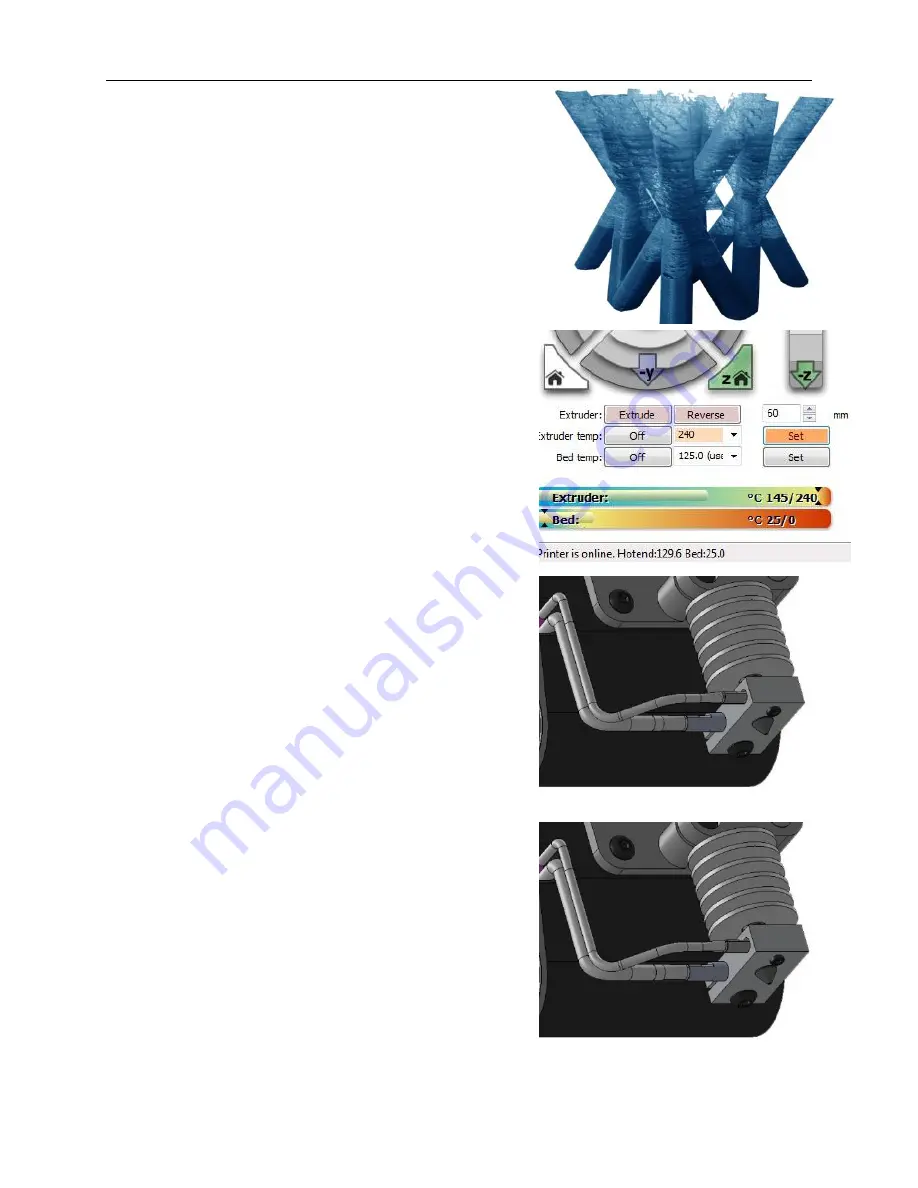

Check the PT100 connections at the extruder and

computer case. If the connections seem OK, replace

the PT100 sensor.

4.

If the heater block is still cold, the problem is likely

the heater cartridge or controller board.

Check the heater cartridge connections in the

extruder and at the case. If the connections look OK,

test the resistance of the heater cartridge and wires

leading to it.

A functioning cartridge should have a resistance of

~3.5 ohms.