25. Reinstall the front driveline, using factory hardware.

26. Install the front tires and wheels. Torque the lug nuts to

wheel manufacturers specifications.

REAR SUSPENSION INSTRUCTIONS

:

27. Jack up the rear end of the vehicle and support the frame

rails just in front of the rear bumper with jack stands.

NEVER WORK UNDER AN UNSUPPORTED

VEHICLE!

Remove the rear tires. Support the rear axle

with a floor jack just enough so that axle does not hang

freely.

28. Working on both sides of the truck and supporting the rear

differential with a jack remove and discard the rear shocks,

save shock hardware. Use care not to over extend the brake

hose.

29. Remove and discard the factory rear sway bar end links.

Save hardware.

30. Locate the lower track bar mount on the axle. Disconnect

the track bar from the axle and save hardware. Pull track

bar free from the factory mount. Remove the factory

plastic trim guard from the trac bar axle mount and discard.

31. Remove the coil springs and discard.

32. Remove the factory rubber bump stop and discard.

33. Working from the driver side of the truck, locate the factory

lower link arm, remove and discard link, save the factory

hardware.

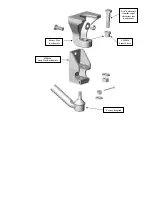

34. Locate the new Fabtech lower link arm FT50018. Install

one of the supplied grease fitting into each end of the new

Fabtech link arm. Using factory hardware install new

Fabtech link arm into the factory frame mount, than attach

to axel mount using factory hardware. Leave loose.

NOTE:

MAKE SURE THE GUSSETS ON BOTH ENDS OF

THE LINK ARM ARE FACING DOWN.

SEE PHOTO

BELOW.

35. If installing Fabtech’s optional upper link kit, install rear

upper at this time. See instructions included in Fabtech’s

upper link arm kit.

36. Locate the new Fabtech bump stop FT50027. Install into

factory pocket by pushing bump stop in until fully seated.

37. Repeat steps thirty through thirty-five on passenger side of

truck.

38. Working from both sides of the truck torque the lower link

arms to 130 ft. lbs.

39. Locate the new Fabtech lift coils FT50005. Install new lift

coils into truck.

40. Locate the new Fabtech shocks FTS

6001

(not included in

kit). Install on truck using factory hardware.

41. Locate the supplied FT50026 rear sway bar end links. Press

in one bushing and one sleeve into each end of the end link.

Install the end links onto truck using stock hardware.

Torque to 45 ft lbs.

42. Locate the new Fabtech rear track bar bracket FT50053BK.

Place the bracket on factory axel mount. With the supplied

½” x 3 ” bolt, nut, washers, and Fabtech sleeve FT46 attach

the lower hole of the bracket to the factory hole in the axle

bracket. (NOTE: THE SUPPLIED SLEEVE WILL BE

PLACED INSIDE THE FACTORY TRAC BAR POCKET

TO TAKE THE PLACE OF WERE THE TRAC BAR

WAS ORIGINALLY MOUNTED). Locate the hole in the

Fabtech bracket on the outer side. Drill a ½” hole through

the factory axle mount. Attach with the supplied ½” x 1¼”

bolt, nut, and washers. Reattach the track bar to the new

bracket with the factory hardware. Torque all trac bar bolts

to 74 ft. lbs. SEE PHOTO BELOW.