Page

15

with

23

Page

15

with

23

Page

15

with

23

Page

15

with

23

MANUAL - KRAMER Technik MIG / MMA 185

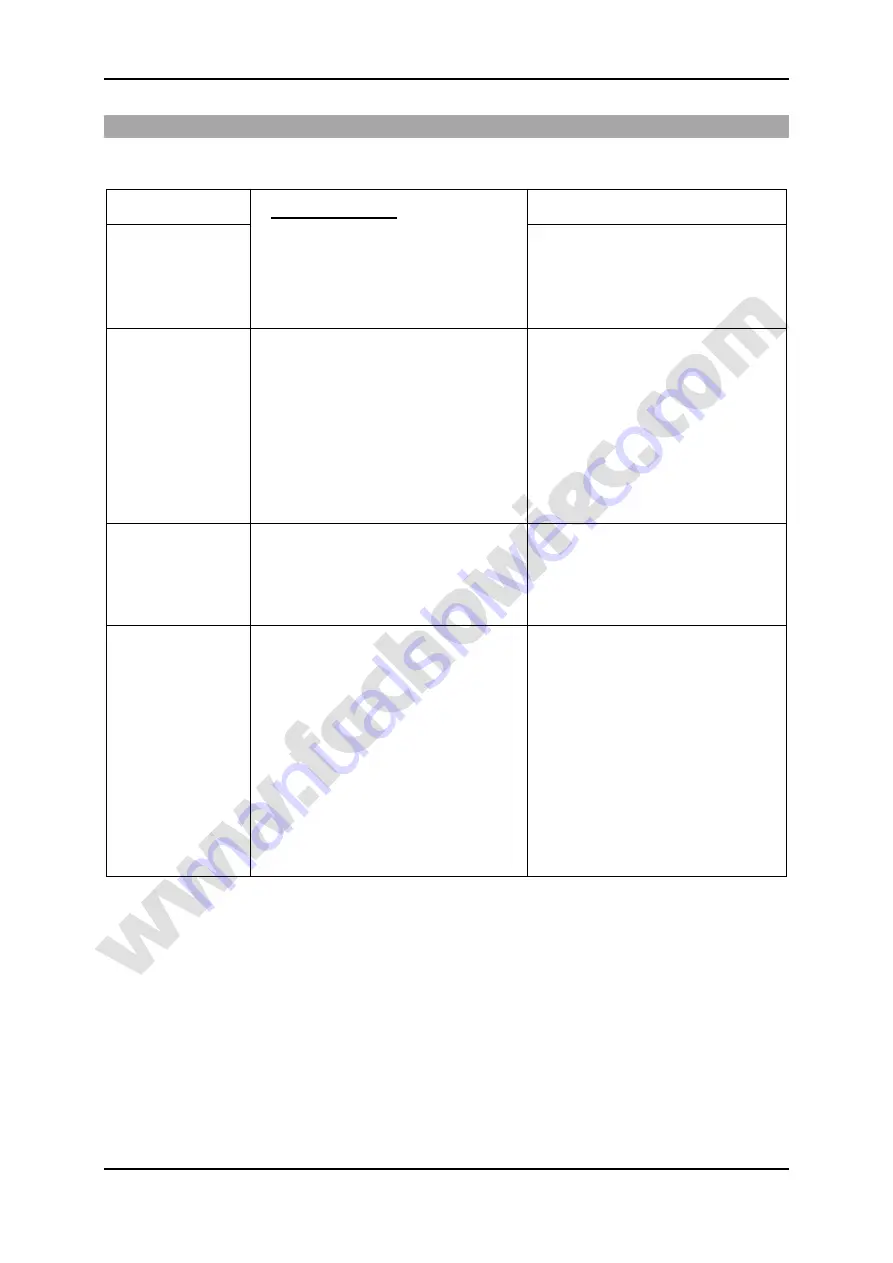

8. TROUBLESHOOTING

8. TROUBLESHOOTING

Table 2.

Troubleshooting

Problem

Possible cause

Solution

The device does

not turn on

The device is not connected to the mains,

device does not receive

input voltage, faulty switch

•

Check whether the device is connected to the

mains

•

Check the voltage in the socket with the help of

specialized meter

•

Check the condition of the fuses

Uneven wire feeding or wire

will not move

The problem with the work

feed roller,

damage to the cartridge guide wire or contact tip

•

Check the pressing force feed roller

•

Check whether the feed roll groove is not damaged

- if so, replace the roll with a new one

•

Check that the contribution of the wire is not

broken / blocked

•

Check that the end of the current contribution and

the guide wire is selected according to the diameter

and type of welding wire

The device has stopped

welding, lit the lamp thermal

protection

attached

himself

system

protective

device

•

Check for excessive voltage drops in the socket,

check if the machine is not overheated, if so -

wait until the welder has cooled

weld quality

is

unsatisfactory

The problem with the proper conduct of the welding

process

•

Check that the wire feed speed is adjusted

accordingly (non-uniform wire feeding)

•

Check the shielding gas, check the gas flow is

adequate

•

Check the settings on the type of

wire

welding

(Material, diameter)

•

Make sure,

that the material

is

properly cleaned

•

Check that the ground terminal is properly

attached

to the workpiece

* If the fault is not eliminated after the application of the in / in tips, contact an authorized service center. Contact

information and operating instructions are on the warranty card [p. 21]