26

6. Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent jamming.

7. With variable speed drills there is no need to center punch the point to be drilled. Use a slow speed to start the hole and accelerate by

squeezing the trigger harder when the hole is deep enough to drill without the bit skipping out.

Operation as a Screwdriver (Fig. 2)

Select the desired speed/torque range using the dual range gear shifter (E) on the top of tool to match the speed and torque to the planned

operation. Insert the desired fastener accessory into the chuck (F) as you would any drill bit. Make a few practice runs in scrap or unseen

areas to determine the proper position of the clutch collar (D). Always start with lower torque settings, then advance to higher torque settings

to avoid damage to the workpiece or fastner.

MAXIMUM RECOMMENDED CAPACITIES

Maintenance

Your FACOM power tool has been designed to operate over a long period of time with a minimum of maintenance. Continuous satisfactory

operation depends upon proper tool care and regular cleaning.

WARNING:

To reduce the risk of serious personal injury, place the forward/reverse button in the lock-off position or turn tool off and

disconnect battery pack before making any adjustments or removing/installing attachments or accessories.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

WARNING:

Never use solvents or other harsh chemicals for cleaning the non-metallic parts of the tool. These chemicals may weaken

the plastic materials used in these parts. Use a cloth dampened only with water and mild soap. Never let any liquid get inside the tool; never

immerse any part of the tool into a liquid.

Charger cleaning instructions

WARNING:

Shock hazard. Disconnect the charger from the AC outlet before cleaning. Dirt and grease may be removed from the

exterior of the charger using a cloth or soft non-metallic brush. Do not use water or any cleaning solutions.

Low Range (1)

High Range (2)

BITS, METAL DRILLING

1/4” (6.35 mm)

1/8” (3.18 mm)

WOOD, FLAT BORING

3/4” (19.05 mm)

1/2” (12.7 mm)

HOLE SAWS

3/4” (19.05 mm)

5/8” (15.88 mm)

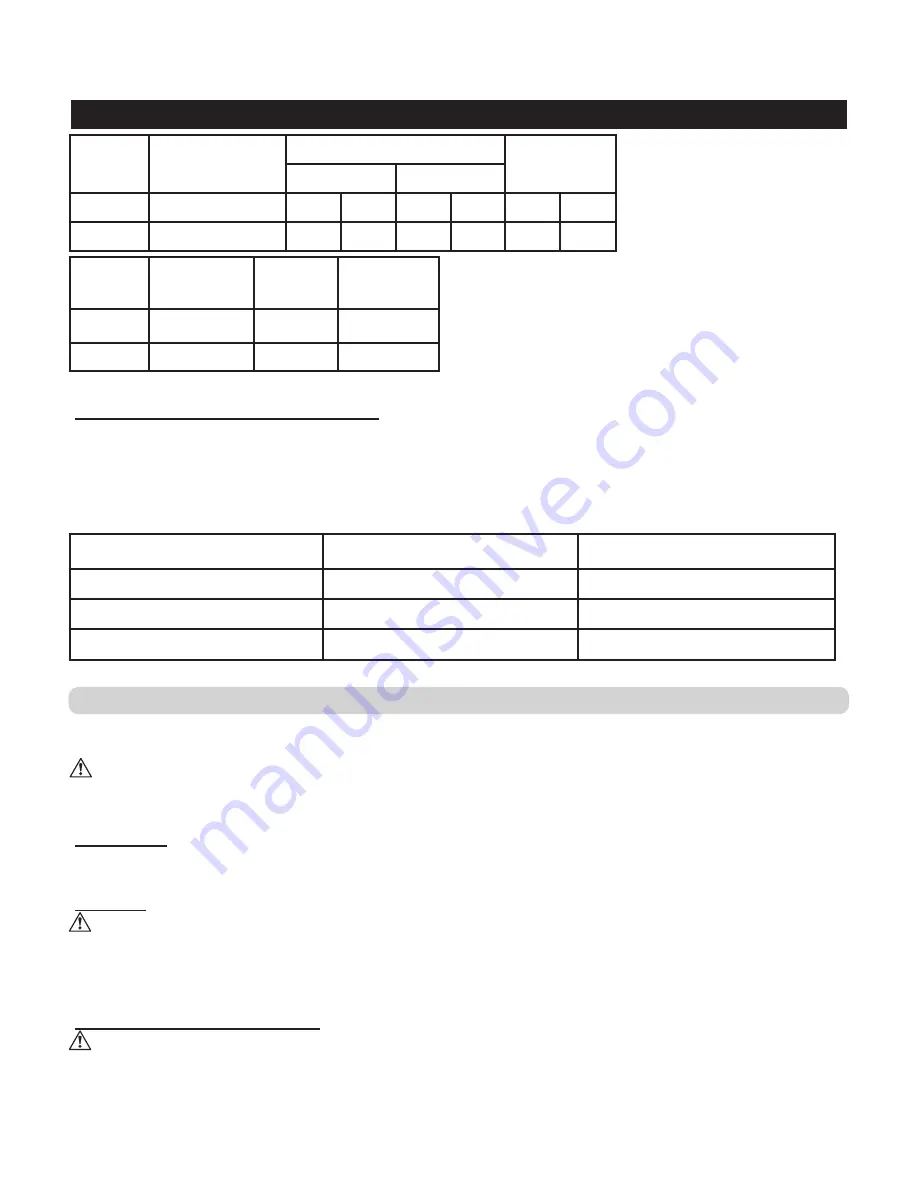

Model

Free speed

Weight

Dimensions

rpm

kg

mm

CL3.P18S

2000

1,2

124 X 191 X 64

Model

Noise level

Vibrations level

m/s

2

Pressure dB(A)

Power dB(A)

in

k*

k*

k**

CL3.P18S

1/2

74

3

85

3

3

1.5

SPECIFICATIONS

* k = measurement uncertainty in dB

** k = measurement uncertainty in m/s

2

Summary of Contents for CL3.P18S

Page 117: ...117 1 2 RCD RCD EL...

Page 118: ...118 3 off on 4 5...

Page 119: ...119 6 CCA V W watt Hz hertz min no I I min RPM IPM BPM A...

Page 120: ...120 FACOM 40 C 105 F on li ion 15 FACOM...

Page 121: ...121 FACOM 2 230V 1 1 2 H 1 3 H...

Page 122: ...122 1 18 24 C 65 F 75 F 4 5 C 40 F 40 5 C 105 F 2 3 4 18 24 C 65 F 75 F 5 6...

Page 124: ...124 FACOM EN 60335 FACOM 3A 1mm2 30 FACOM D C A F 2 E B G H E I...

Page 125: ...125 4 H G 2 A 2 B OFF 2 C D 20 3 D 3 E 4 H G D E 3...

Page 126: ...126 5 1 OFF 2 3 19 3 4 2 OFF 6 D E 1 6 4 1 4 Torx 6 7 6 4 1 4 off off 5 6 7 E D E D...

Page 142: ...142 CL3 BA1830 CL3 CH1018...