7

Contents:

Check the contents of your pack.In case of missing

items, inform your distributor before commissioning.

INSTALLATION AND COMMISSIONING

Moving the machine (see page 31)

Place your U217AS on a flat, stable surface, (eg

concrete plinth);level the machine.

Warning:

Ensure sufficient clearance.

Mounting the flange:

After selecting the flange required, make sure both

flange and spindle are clean before assembly.

Tighten securely using the UA.CF13 wrench (see

page 31).

Connection:

Connect your U.217AS to the mains 220/240V mono

360W 50Hz with earth.

Switching on:

Switch on the machine (reference mark C). The

U.217AS will display 207, the programm version and

3 dashes. After initial adjustment, the U.217AS is

ready for long service.

GENERAL SAFETY RULES

The wheel balancing system must only be used by person-

nel with proper training and qualifications, and only within

the range of applications for which it is designed (eg for

wheel-balancing on light passenger and light utility vehicles

or motor-cycles) in accordance with the instruction manual

and with FACOM-approved tooling for wheel retention.

It is forbidden to remove or render the system of safety

mechanisms inoperative.

Facom accepts no liability for damage or injury caused by

system operation where these arise from unauthorised chan-

ges made to the wheel-balancer or to its accessories. All

work on the electrical or electronic systems must only be

carried out by authorised and qualified personnel.

The system operator must abide by general rules for safety

at work (protective gloves, footwear, etc...).

MAINTENANCE

Before carrying out any maintenance or troubleshooting on the

wheel-balancer, disconnect from the power supply. Dismantle and

lubrificate the flange. Regularly wipe the spindle nose with an

oily cloth. Clean the front panel regularly with methylated spirits or

silicone-based cleaning products. Never use organic solvents such

as trichlorethylene, petrol, acetone or other thinners. Avoid water

splashes either inside or outside the machine.

If the system seems to be malfunfioning, do not remove or dismantle

any part of the apparatus until you have checked:

- That the power supply is properly connected

- That the flange is correctly fixed in place and that vehicle

wheels are firmly held

- That wheel rim dimensions have been correctly entered.

other anomalies

- contact After Sales Service*

*See last page.

TECHNICAL CHARACTERISTICS

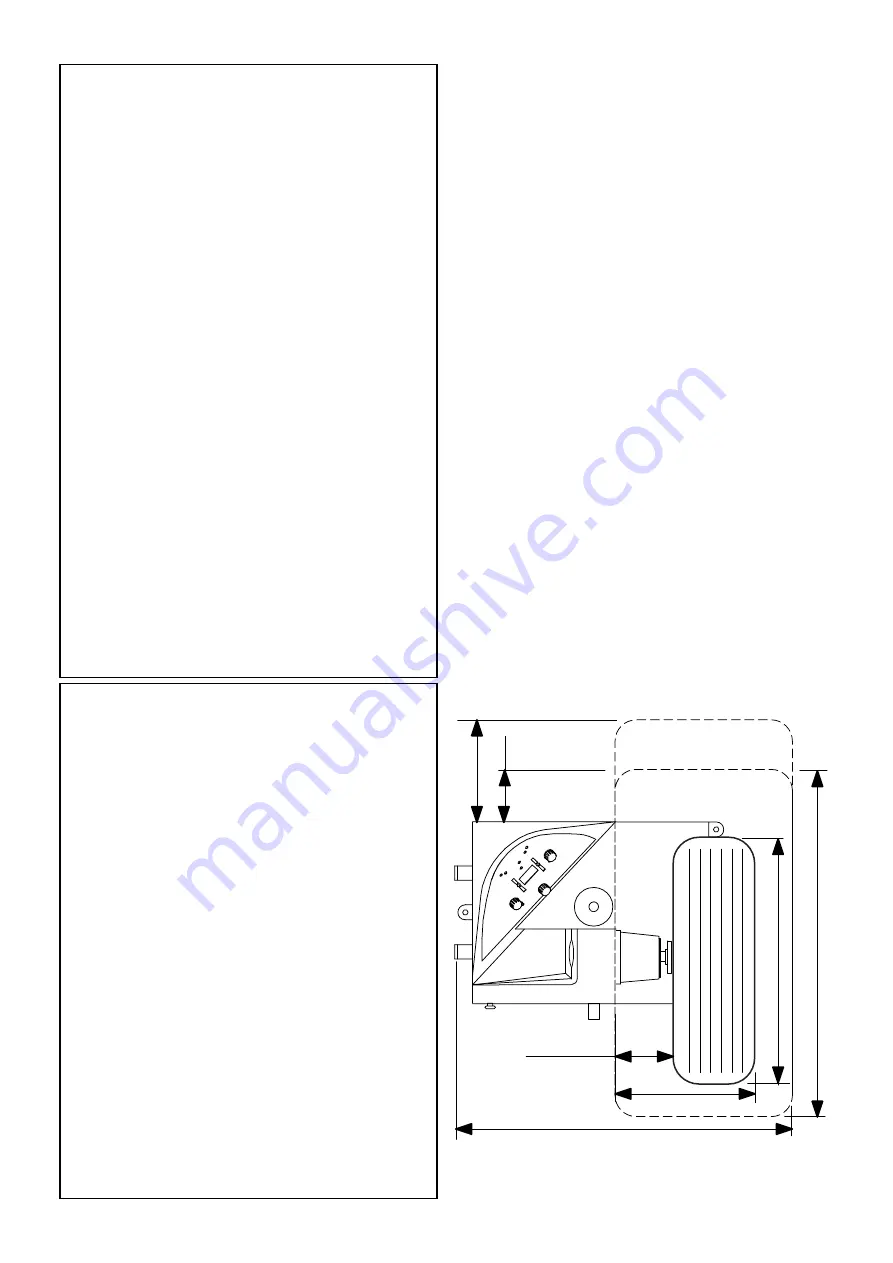

Machine dimensions

(see drawing on the other side)

Weight: ..........................................................86kg

Electrical supply

single phase: ............................... 230V±30V,50Hz

Electrical protection category

for machine: ....................................................IP52

Moteur power rating: ...................................... 50W

Balancing speed: ...................................... 140 rpm

Mesurement duration: ........................... 12 seconds

Max unbalance: .............................. 199g or 6,9oz

Precision of measurement

for weights:......................... 1 or 5g/0,1 or 0,25oz

Prescision of measurement

for positioning: ................................................ 1,4°

Operating temperature: ........................ 0° to 45° C

Relative humidity: .................. 5 to 95% HR at 45° C

Noise level: ............................................ 70 db (A)

Measurement capacity

Machine-Wheel rim distance: ............ 50 to 315 mm

Wheel rim width: ..................................... 2" to 13"

Wheel rim diameter: ................................ 8" to 24"

Total wheel diamèter:................................. 820 mm

Max. load on the spindle: ...........................70kg

50 mini

290

550 maxi

820 MAXI

980

1030

h:1050

140

Summary of Contents for U.217AS

Page 3: ...3 6 x 2 x 2 x 4 x 4 6...

Page 31: ...31...

Page 32: ...32...

Page 33: ...33...

Page 34: ...34...

Page 36: ...36 U 217A 18SAV U 217A 19SAV U 217A 21SAV U 217A 20SAV U 217A 22SAV U 217A 23SAV...

Page 40: ......

Page 42: ......

Page 43: ......

Page 44: ......