1/4 NPT

Ø 10 mm

3/8 "

CE DECLARATION OF CONFORMITY

WE, FACOM S.A.S., 6/8 RUE GUSTAVE EIFFEL - 91 420 MORANGIS - FRANCE, DECLARE UNDER OUR OWN RESPONSIBILITY THAT THE PRODUCT

V.PF300F

– FACOM PUNCH AND FLANGE TOOL

- IS IN CONFORMITY WITH THE

«MACHINERY» DIRECTIVE 2006/42/CE

- AND IS IN CONFORMITY WITH THE PROVISIONS OF THE HARMONISED EUROPEAN STANDARD

EN

ISO 11148-10: 2011

The undersigned is responsible for compilation of the technical fi le and makes this declaration on behalf of Facom.

20.03.2016

Director Engineering

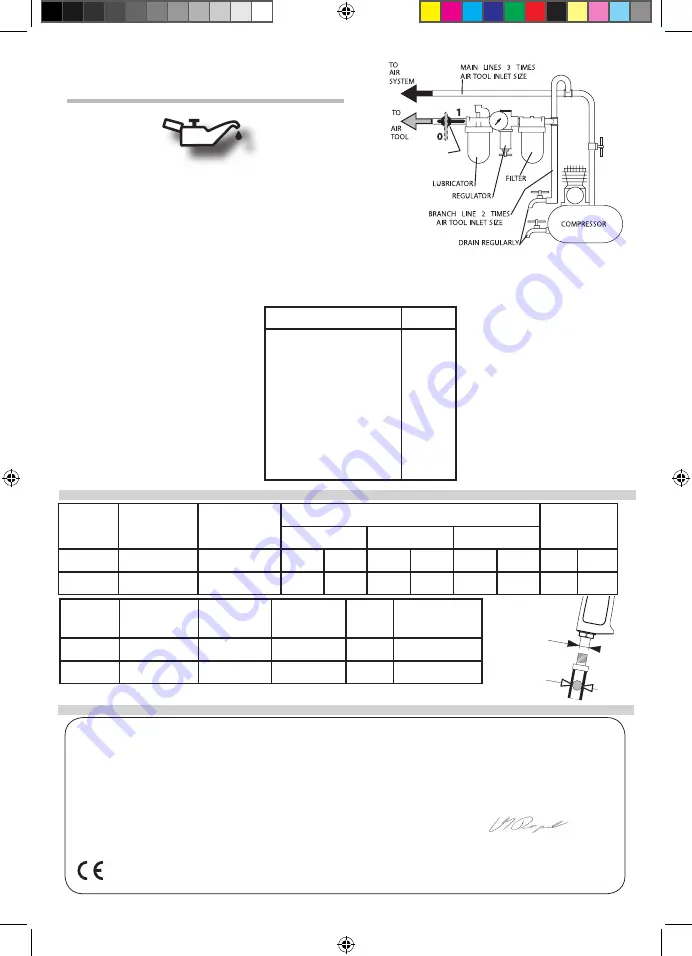

PLACING THE MACHINE IN SERVICE

EMERGENCY

GATE VALVE

* k = measurement uncertainty in dB ** k = measurement uncertainty in m/s²

LUBRIFICATION

Always use of an air line lubricator with these machine. We recommended the

following Filter-Lubricator-Regulator Unit:

FACOM N.580

.

Every eight hours’ operation, if a lubricator is not used on the compressed air

network, inject 1/2 to 1cm

3

through the machine’s inlet connection.

Model

Punch diameter

Punch capacity

Noise level

Vibrations level

m/s

2

Pressure dB(A)

Power dB(A)

Pressure dB(C)

mm

mm

k*

k*

k*

k**

V.PF300F

8

1

81

3

92

3

79

3

2,1

0,7

Model

Flange capacity

Air

consumption

Working

pressure

Weight

Dimensions

mm

l/min

bar

kg

mm

V.PF300F

1,2

113

6,2

1,1

175

Markus Rompel

Total average air required (CFM)

Conp. Hp

0 - 11.9

12.0 - 18.5

18.6 - 24.2

24.3 - 36.4

36.5 - 51.0

51.1 - 66.0

66.1 - 88.2

88.3 - 132.0

132.1 - 176.4

176.5 - 200.0

1

1 - 1/2

2

3

5

7 - 1/2

10

15

20

25

Average Air Supply by Compressor Horsepower

NU-V.PF300F_0716.indd 8

08/07/2016 08:26:24

Summary of Contents for V.PF300F

Page 49: ...FACOM 1 2 1 3 FACOM FACOM FACOM NU V PF300F_0716 indd 49 08 07 2016 08 28 01...

Page 54: ...RU FACOM 6 2 620 10 6 2 6 2 NU V PF300F_0716 indd 54 08 07 2016 08 28 06...

Page 55: ...FACOM 1 2 1c 3 FACOM FACOM FACOM C NU V PF300F_0716 indd 55 08 07 2016 08 28 08...

Page 61: ...NOTA NU V PF300F_0716 indd 61 08 07 2016 08 28 19...