PAGE 10

connector. Shake the filter.

lever.

door (3 screws).

up the slot on the broom with the

driver's slots. Push the broom all the

way in.

forward when viewed from the top.

SPECIAL NOTE:

Always "park" the main broom when

machine is not in use.

If you leave the main broom on the floor

for an extended period without turning

it, you will put a flat spot in its fiber.

This will cause "broom bounce" and

bad sweeping.

Remove (1) Hopper, (2) Access

Panel, (3) Idler Arm (1 Bolt), and then

remove (4) the old Broom.

BATTERIES:

The highest maintenance item

on your machine will be its storage battery.

Please read the "About Batteries" section of

this book.

MAIN BROOMS:

Replace the main brooms

when they stop sweeping to your standards.

We recommend you use our brooms. They

are made for your machine. Our brand of

broom has a precision plastic core that is

carefully balanced and has machined insert

points so the broom fits tightly on the

machine's hubs. Brooms made by "will fit"

companies to fit our machines are often

made with rough drain-pipe cores. They

often bounce even when new. Bouncing

brooms do not sweep.

A new main broom has two and a half inches

of fiber on it. Normally, a main broom with

one and a half inches or less of fiber will not

sweep as well as a new broom.

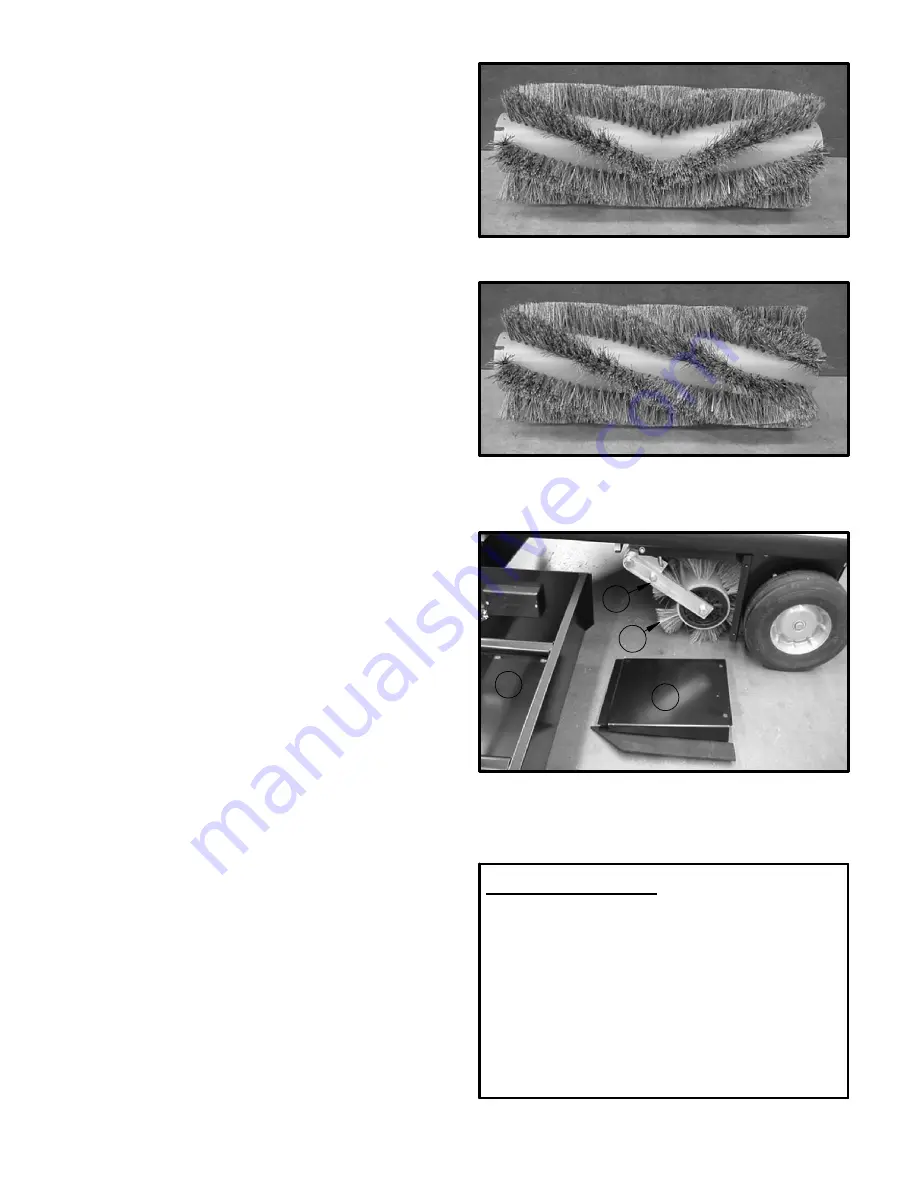

We recommend the "Vee" type filter pattern,

which is able to fit the hopper fuller than the

"Spiral" type filter pattern.

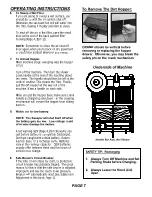

MAIN BROOM REPLACEMENT

Note that you do not need to reverse the

broom periodically - as on other brands -

because our broom suspension does not

bend and splay the outerfibers of the broom.

TO REPLACE MAIN BROOM:

1. Turn off machine and unplug battery

2. Raise main broom off ground with broom

3. Remove dirt hopper and broom access

4. Unbolt broom as shown (Item 3 in photo).

5. Pull out old broom.

6. Push on new broom-being careful to line

7. Make sure "Vee" of the Vee broom points

MACHINE MAINTENANCE

MAIN BROOM

Vee-Broom.

Preferred Style

Spiral-Broom.

Does not

sweep as well as Vee-Broom.

1

2

3

4