4

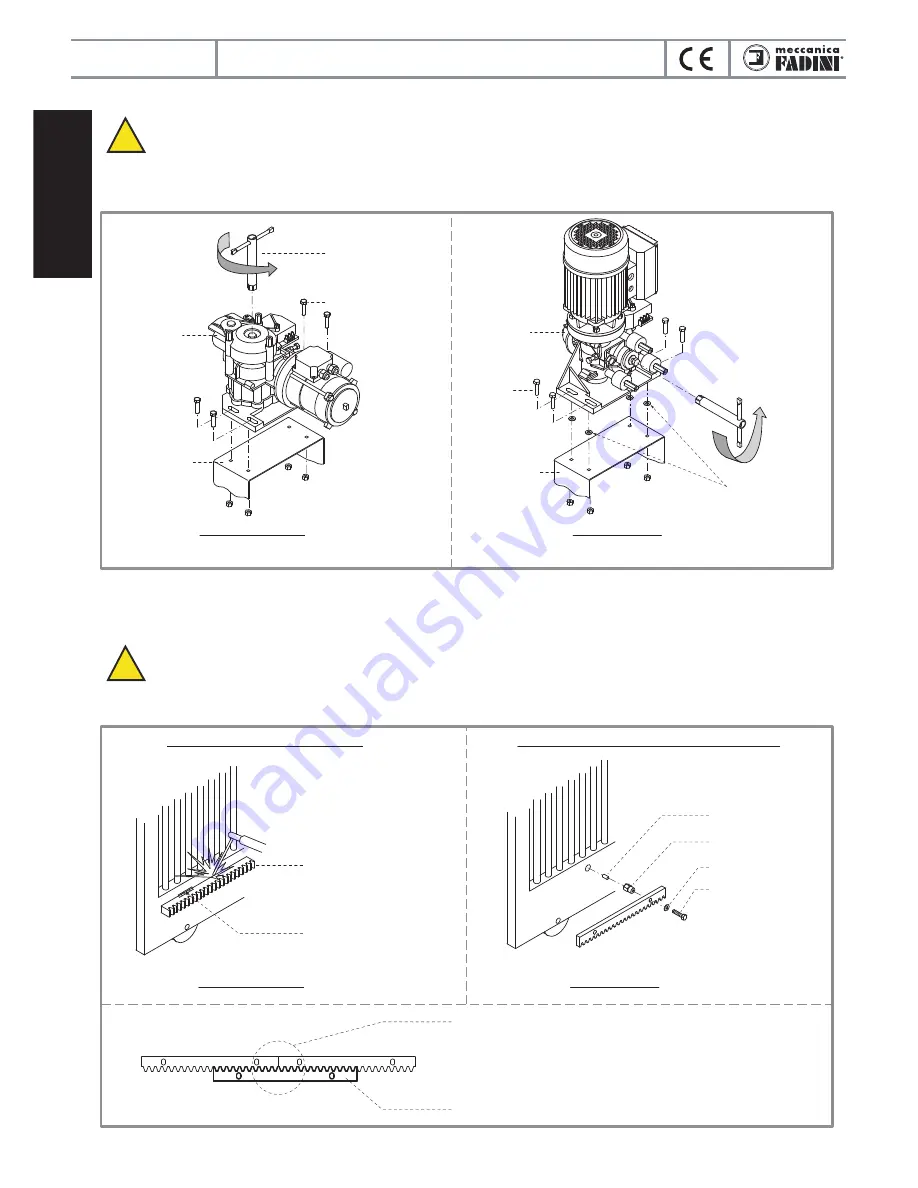

RACK FITTING OPERATIONS

IMPORTANT:

if installing Mec 200 vertical it is recommended to insert 2 mm shims between the fixing bracket and

the operator base plate before welding the rack to the gate, so that rack and gear mesh each other with an adequate

clearance after that the shims have been removed.

Temporary fix Mec 200 on to the fixing bracket, perfectly levelled, by means of the 4 fixing screws. Mec 200 outer gear must run

idle: loosen (by 1 or 2 turns max.) the hexagonal head screw by means of the release spanner E 17 supplied with the equipment

(pic. 3).

While fixing the rack it is required that the Mec 200 driving gear is not connected with the gate and it can be made run idle by means

of the release spanner E17 supplied with the equipment; the gate can be freely moved by hand.

Temporary clamp the rack to the gate so that it can adequately mesh the driving gear: the rack must mesh the driving gear, idle, of

Mec 200 in a very smooth way, without friction (pic. 4).

IMPORTANT:

before definitely fixing any component, make sure that the rack can mesh the driving gear of Mec 200

so that the whole system, gate included, can be smoothly run by hand the full travel open and close without any

friction.

Remove the 2 mm shims only after having fixed the rack. An adequete clearance between rack and gear has thus been achieved

(pic. 4).

English

Pic. 3

Pic. 4

MEC 200

MEC 200 HORIZONTAL

MEC 200 VERTICAL

MEC 200 HORIZONTAL

MEC 200 VERTICAL

RACK FIXING BY WELDING IT TO THE GATE

RACK FIXING BY MEANS OF SCREWS AND FITTING PARTS

ANTI-CLOCKWISE

TO RELEASE

RELEASE SPANNER

E 17.

ANTI-CLOCKWISE

TO RELEASE

DRIVING GEAR

OR SPROCKET

RELEASE SPANNER E 17

M8 FIXING SCREWS

DRIVING GEAR

OR SPROCKET

M8 FIXING

SCREWS

FIXING BRACKET

FIXING BRACKET

22x22 mm RACK, 2 m LENGTH

THREADED PIN

DISTANCE NUT

WASHER

M8 SCREW

RIGID SPOT WELDING

PITCH GAUGING SPARE RACK

IMPORTANT:

respect the same rack pitch when

joining the rack bars. Use a spare rack bar as in the

picture to make sure that the junction has the same

configuration.

2 mm SHIMS TO

REMOVE AFTER

HAVING FIXED THE

RACK TO THE GATE

!

!

electro-mechanical sliding gate operator