2

Ø 200

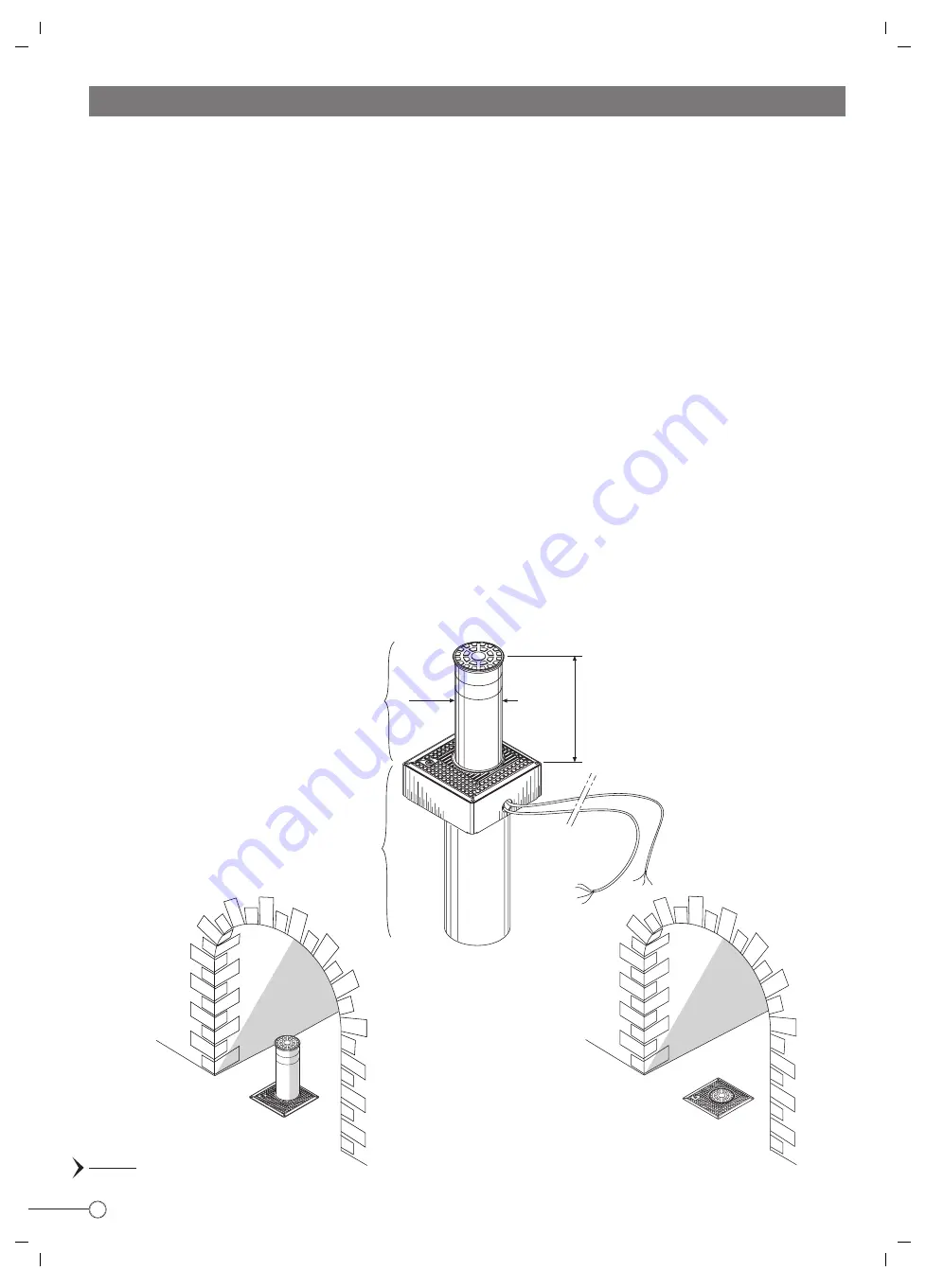

PIC. 1

INSTRUCTIONS TO FOLLOW FOR THE INSTALLATION OF THE AUTOMATION VIGILO 2250

IGILO

2250

V

FOR A PERFECT APPLICATION AND CORRECT PERFORMANCE OF THE EQUIPMENT IT IS RECOMMENDED TO FOLLOW THESE

INSTRUCTIONS AND DIAGRAMS

IMPORTANT: THE INSTALLATION IS TO BE CARRIED OUT BY A QUALIFIED TECHNICIAN IN COMPLIANCE WITH THE SAFETY NORMS

EN 12453 - EN 12445, AND THE MACHINE DIRECTIVE 98/37/CE. A COMPLETE RISK ANALYSIS IS TO BE MADE IN COMPLIANCE WITH

THE EXISTING SAFETY REGULATIONS

GENERAL FEATURES

This product can be classified as a type of automated bollard, fully retractable into the ground. It is easy and simple to install as no

special adjusting or calibration is required. The main application is traffic control. VIGILO 2250 is an electro-hydraulically operated post

having a Ø 200 mm diametre and a max. stroke of 500 mm.

The main advantage of this product is semplicity of installation: soon after fixing the location enclosure, fit the mechanism into it, carry

out the electrical connections and the system is ready to work.

Once a pulse is given (either by keyswitch or remote control), the post starts rising. A reflecting sticker makes it well visible, and an

optional flashing lamp or traffic lights ensure clear indication of the post movements or status. An electronic control panel fitted with

a microprocessor allows full automatic operations as required (optional sensing loops, photocells etc. ...) can be connected.

PRELIMINARY LOCATION CONSIDERATIONS

Before commencing installation ensure that:

- The area where the enclosure is to be located is free from underground services, which may interfere with installation.

- The properties of the soil are adequate to the required application.

- No obstruction interferes with the post movements.

Vigilo 2250 flush

with road level

to allow access

Stroke 500 mm

Vigilo 2250 raised

above ground level

to stop traffic

The post is vertically operated to

rise above the road pavement

Enclosure assembly to be

located underground in a

suitable pit

Cable length 10 metres

Summary of Contents for VIGILO 2250

Page 1: ...FITTING INSTRUCTIONS GB ...