5

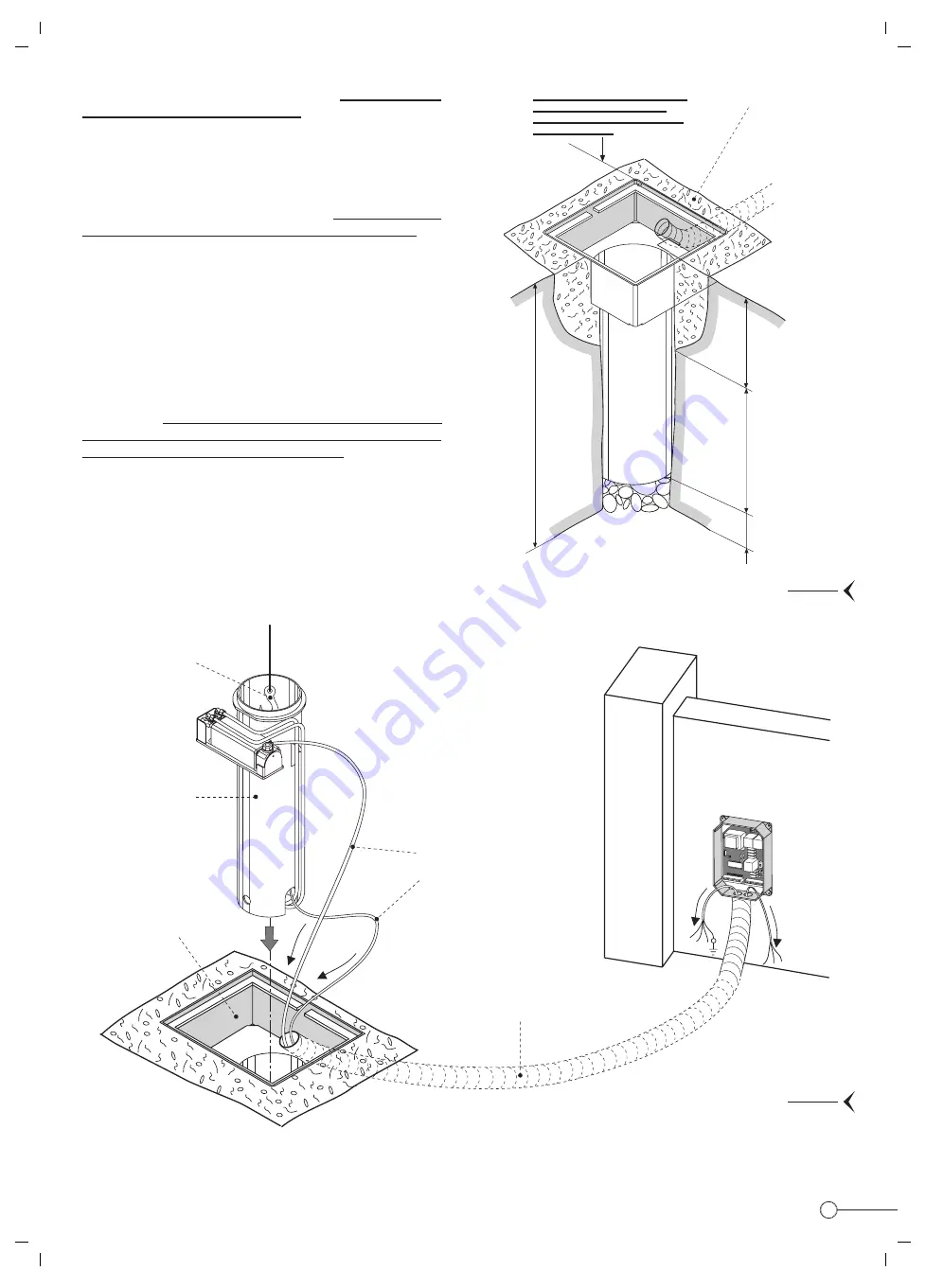

PIC. 6

30 cm

55 cm

15 cm

1,0 m

PIC. 7

- Once located the enclosure into the pit, it is important that the

top edge is flush with the ground level.

- Fill with soil up to 55 cm and the remaining 30 cm with concrete

Pic. 6

INNER ASSEMBLY INSTALLATION

For this operation it is fundamental that the location enclosure

is very firmly set in its foundation, therefore it has to be carried

out only after you are satisfied that the concrete is well set and

the electrical duct coupled to the enclosure and laid under the

ground.

- A suitable lifting harness should be passed through the eye in

the bollard top and attached to a lifting mechanism. The assembly

should be raised from the ground and positioned directly above

the location enclosure.

- Next step. The motor and the limit switch cables should be

pulled through the duct (a rope pull-through previously inserted),

and the inner assembly gently lowered onto the location enclosure.

IMPORTANT: Pull the electric motor and limit switch cables

through the duct to the control unit. Be careful not to damage or

remove the cables from their termination Pic.7

Once satisfied that the guide tube assembly is properly fitted inside the location enclosure, fit back the bollard lid and the enclosure

cover plate (Pic. 8 on page 6).

FRONT SIDE

BACK SIDE

IMPORTANT: Once the installation

operations are completed the

enclosure top edge must be flush

with road surface

55 cm

approx.

Fill this distance

with soil

30 cm

approx.

Fill this distance

with concrete

Concrete foundation

15 cm

approx.

Shingle to clear

of standing water

Foundation

enclosure

FRONT SIDE

Electronic control unit

Elpro 10 PLUS CEI

Ø50 mm duct laid

under the ground

Electric motor and limit

switch cables, 10 m length

Guide tube

assembly

Lifting harness

Summary of Contents for VIGILO 2250

Page 1: ...FITTING INSTRUCTIONS GB ...