English

18 EN

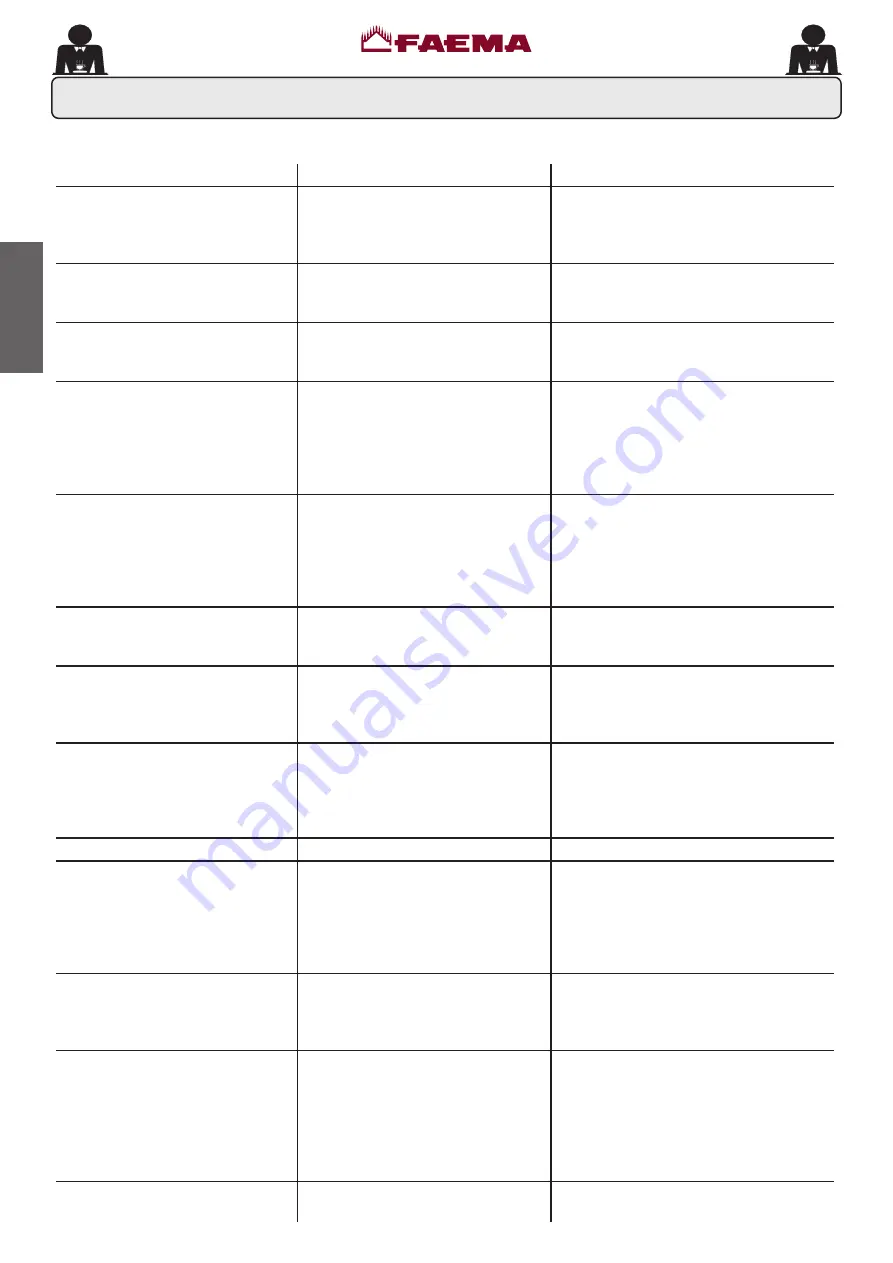

17. Defects - Malfunctions

Interventions by a specializes technician

PROBLEM

CAUSE

SOLUTION

Dispensing slow.

Coffee burnt and cold.

Cream very dark, with tendency of

formation of an “eye”.

Coffee grounds too fine.

Low pressure in pump.

Mesh filter above spout dirty.

Spout partially blocked.

Dispensing slow, coffee burnt.

Pressure gauge pump lower than

131 psi (9 bar).

Pump out of calibration.

Pump with reduced capacity.

Drainage tube leaks when group is

at rest (defect only on one group).

Coffee dispensed normally.

Dispensing valve does not hold.

If this defect is not corrected immediately, the

water softener runs out long before the expiry

time, with consequent scale deposit.

Group at rest

Dispensing valve gasket fails

rapidly.

Water leak from the drainage tube.

Coffee dispensed normally.

Defect on all groups.

Expansion valve with calibration too

high (above 174 psi (12 bar).

If this defect is not corrected immediately,

the water softener runs out long before

the expiry time, with consequent scale

deposit.

Group at rest.

Continuous loss of cold water in

the drainage tray. Groups do not

dispense any more coffee and the

pressure gauge pump shows low

values.

Expansion valve remained open.

If this defect is not corrected immediately,

the water softener runs out long before

the expiry time, with consequent scale

deposit.

Group in operation.

Drainage tube leaks.

No coffee.

Drainage valve does not hold.

Group in operation.

Loss of cold water in drainage tray.

Coffee bland.

Dispensing slow.

Expansion valve out of calibration

(opens at less than 131 psi (9 bar).

Group leaks at cam shaft.

Leak on the two glands.

Remove the glands taking care not to mark

the housings. Do not use tools made of

steel or other hard materials.

Before remounting, clean the shaft

thoroughly, especially the grooves

Difficult to move the groups.

Cam profile worn.

Machine does not go into pressure

or reaches pressure level slowly.

No electricity.

Automatic switch gone off.

Resistances burned.

Electric circuit to resistance

interrupted.

No water in boiler.

Steam taps leak:

Groups function normally.

Pressure gauge pump does not give

correct pressure reading 116 ÷ 131

psi (8 ÷ 9 bar).

Pressure gauge defective.

Pump does not reach pressure

level.

No dispensing.

Motor does not work:

- No electricity.

- Capacitor burnt.

- Microswitch burnt.

- Motor burnt.

Check valve pump open.

By pass valve completely opened.

Pump noisy.

Pump defective.

No water in system.

Summary of Contents for E61 Legend

Page 23: ...A B C D E ...