Schaeffler Group Industrial

BA 20

13

Setting the end position

The end position is reached when the rolling bearing has been

moved the displacement distance. The displacement distance can

be read off, for example, in FAG Mounting Manager.

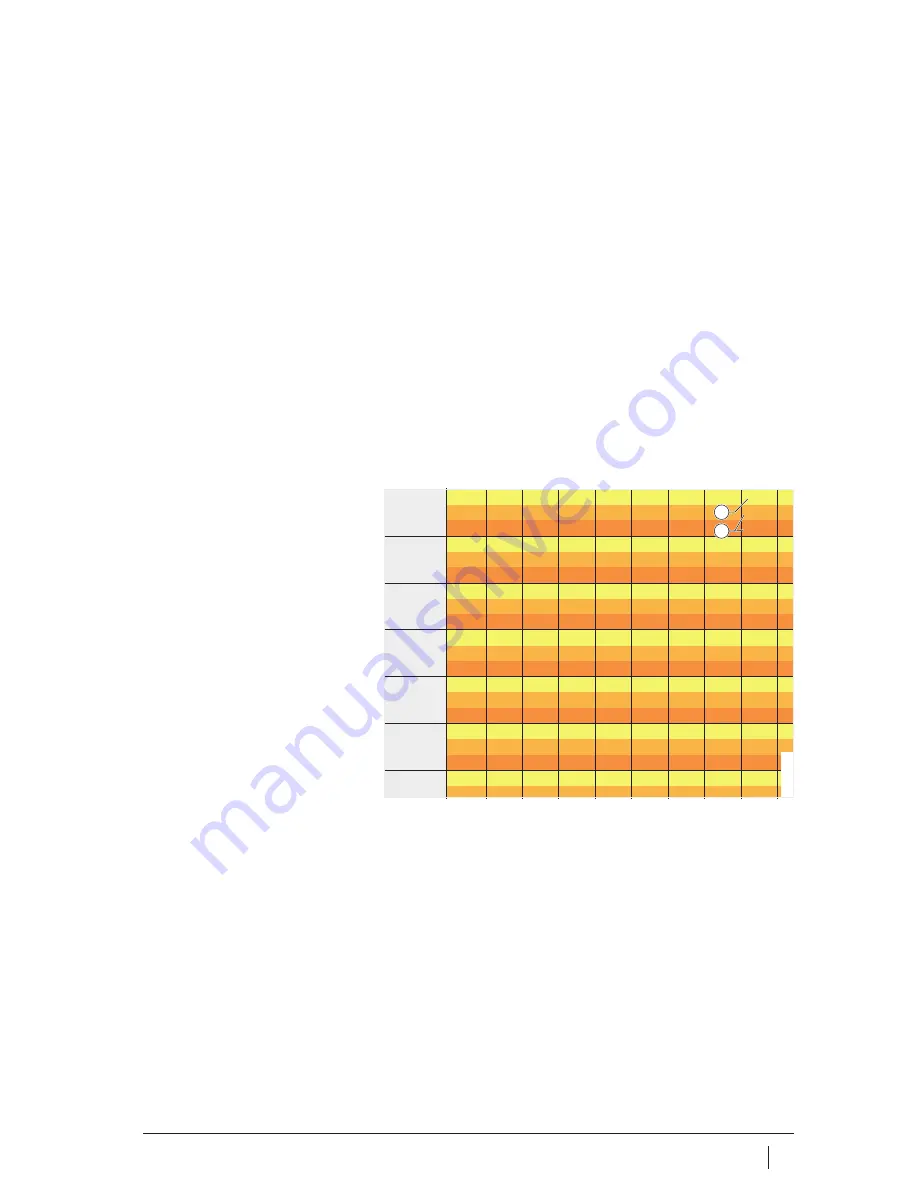

Determining the number of strokes

The number of strokes can be read off on the basis of

the displacement distance and the hydraulic nut used,

Figure 8

,

and the value table, starting from page 24.

Example

The following hydraulic nut is used for mounting of bearings:

■

HYDNUT160.

When using HYDNUT160, any spacer ring present must be

dismounted, see the section Spacer ring, page 9.

The software FAG Mounting Manager determines the displacement

distance as follows:

■

0,94 mm.

The next highest displacement distance is 1,01 mm and the number

of strokes is as follows, see the value table:

■

10 strokes for mounting with hydraulic support

■

12 strokes for mounting without hydraulic support.

Next highest displacement distance

Number of strokes

Figure 8

Value table, excerpt

160

s

mm

0,52

0,57

0,63

0,69

0,76

0,84

0,92

1,01

1

x

1

–

5

6

6

7

7

8

9

10

11

x

2

–

6

7

7

8

9

10

10

12

13

170

s

mm

0,55

0,61

0,67

0,73

0,81

0,89

0,97

1,07

1

x

1

–

6

6

7

8

9

9

10

11

13

x

2

–

7

7

8

9

10

11

12

13

15

180

s

mm

0,57

0,63

0,69

0,76

0,83

0,92

1,01

1,11

1

x

1

–

7

7

8

9

10

11

12

13

14

x

2

–

8

8

9

10

11

12

13

15

16

190

s

mm

0,61

0,67

0,74

0,81

0,89

0,98

1,08

1,19

1

x

1

–

8

9

10

10

12

13

14

15

17

x

2

–

9

10

11

12

13

15

16

18

19

200

s

mm

0,64

0,7

0,77

0,85

0,94

1,03

1,13

1,25

1

x

1

–

9

10

11

12

13

14

16

17

19

x

2

–

10

11

12

14

15

16

18

20

22

210

s

mm

0,7

0,77

0,85

0,93

1,02

1,13

1,24

1,36

1

x

1

–

11

12

13

14

15

17

19

20

23

x

2

–

12

13

15

16

18

19

21

23

26

220

s

mm

0,7

0,77

0,85

0,93

1,02

1,13

1,24

1,36

1

x

1

–

11

12

14

15

16

18

20

22

24

1

2

00

01

60

64