(20/35) - DRO installation - Installation/Operation - 10iE-20iE - (Soft: 01.xx)

3.5.2

Operating mode.

• Move the axis to the origin or zero point and press the axis key.

The display shows

“START”.

• Move the axis in the positive direction all the way to the end of the travel so

the DRO can read as many reference marks as possible.

• Press

[ENTER]

to finish. The moving direction used will be assumed as the

positive direction.

The axis status will then switch to one of the following:

Ready

Correct feedback setup

Repeat

Wrong feedback setup, the process should be repeated.

Error

Error in the feedback system.

Note:

If the feedback device is a steel tape t ype linear encoder, press

[F]

before

pressing

[ENTER]

so it is properly detected.

3.5.3

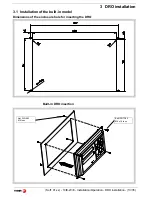

Power and machine connection

Always mount it vertically so its keyboard is within operator's reach and its

digits are easily visible (at operator's eye level).

Do not connect or disconnect the DRO connectors while it is under power.

Connect all metallic parts to a common point on the machine tool and it to the

general ground point. Use cables of enough gage (no thinner than 8 mm

2

)

for this connection.

3.6 Installation parameters

These DROs have a number of insta llation parameters to configure it for a

particular application.

The way th ese parameters are displayed depends on whether they are

general or particular for each axis.

• If it affects the axes, the parameter number (PAR??) appears on each axis

display and the corresponding axis key must be pressed to modify it.

• If it is a general parameter and there are more than one axis (20iE, 20iE-B) ,

the X display will show the parameter number and the Y its current value; if

there is only one axis, its number will appear on the X displa y and, after

pressing this key, its value.

There are several kinds of parameters depending on how to set them:

• With binary values, it only takes values of 0 or 1 for each digit. The value is

changed by pressing the key with the relevant digit between [1] and [8].

Where [1] corresponds to the rightmost digit o f the display a nd [8] to the

leftmost digit.

• Numeric values, usually with the corresponding axis reso lution, they are

entered as regular coordinate preset.

to