DC Servo Drive System Manual Ver: 0009

DC - 4/32

1.1

INTRODUCTION

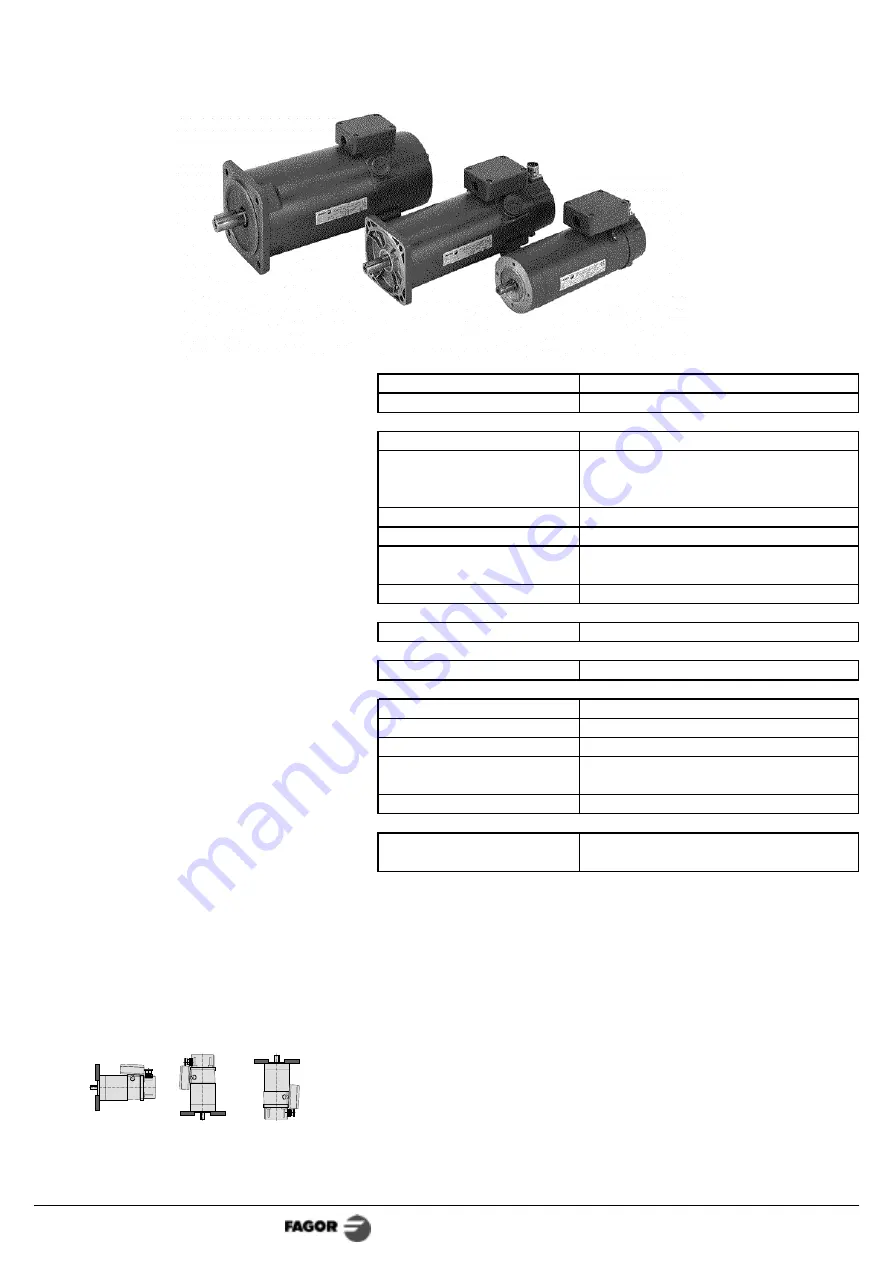

Fagor DCM motors (DC) are

especially designed to be

controlled by Fagor DC

servo drives.

These DC motors are easier

and less expensive to govern

than brushless motors.

Its mechanics is an industrial

standard.

DC Motors, DCM

DCM4

DCM2

DCM5

(*) The diagram below shows

the meaning of the mounting

codes.

(**) IP44 means that it is protected against particles with

a diameter greater than 1 mm and against water splashes

in all directions.

Winding voltage

100-130 Vdc

Number of poles

2 (DCM2); 4 (DCM4 and DCM5)

Shaft end

Cylindrical with keyway.

Mounting

Face flange.

(meets IEC-34- 7-72)

B14, V18, V19 on DCM2;

B5, V1, V3 on DCM4 and DCM5.

Mechanical tolerance

Standard class (meets IEC 72/1971)

Bearings life

10000 hours

Balancing

Class N (meets DIN 45665)

(balancing with keyway)

Noise

Meets IEC 34-9-72

Brake (optional)

24 Vdc

Electrical Insulation

Class F

Degree of protection

IP44 (**)

Operating temperature range

From 0°C to +40°C (32°F to 104°F)

Maximum overtemperature

130°C (266°F)

Thermal switch

N. C. 120°C (248°F)

13 Amp (250 Vac); 18 Amp (24 Vdc)

Maximum altitude

1000 meters (1281 ft) above sea level.

Feedback

20 Volt/Krpm tachometer

2500 lines/turn encoder TTL

(***) The F class isolation on the motor maintain the

dielectric properties as long as the work temperature

stays below 155°C (311°F).

B14/B5

V18/V1

V19/V3