N

EW

F

EATURES

(S

OFT

M: 7.

XX

)

80

40 CNC

Functions

associated to

machine safety

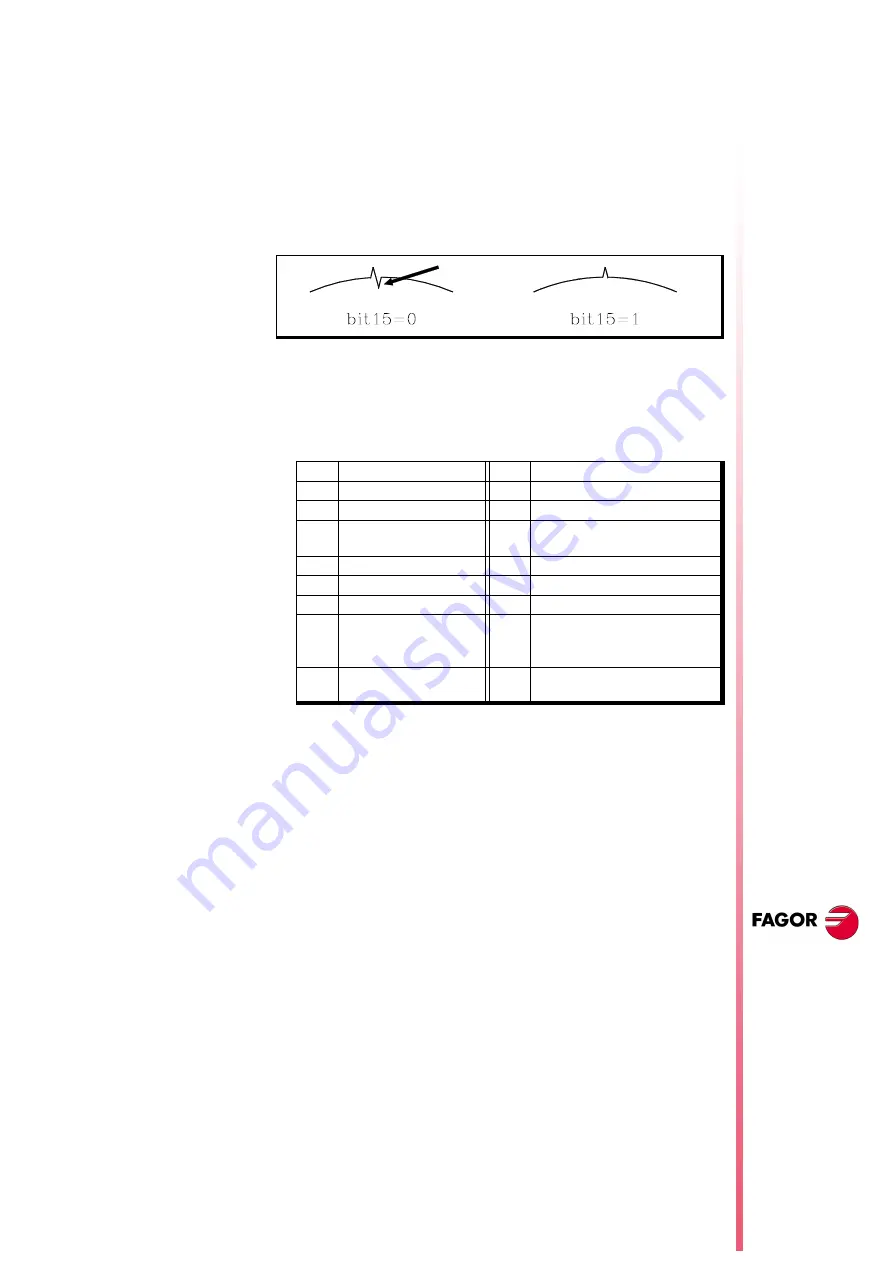

Bit 16 of g.m.p. “ACTBAKAN (P144)” indicates the backlash peak

being used.

A finer tuning of the leadscrew backlash consists in testing the circle

geometry and watch for internal peaks when changing quadrants

(left figure). In these cases, it is recommended to set bit 15 of g.m.p.

“ACTBAKAN (P144)” to "1" to eliminate the internal peaks.

Under these conditions, the CNC eliminates the leadscrew backlash

peak as soon as it detects a movement reversal. If the internal peaks

are not eliminated, adjust the leadscrew backlash compensation

better.

ACTBAKAN (P144)

It has 16 bits counted from left to right.

By default, all bits are set to "0".

19 Functions associated to machine safety

19.1 Limit the feedrate of the axes and the spindle speed

It is possible to limit the feedrate of the axes and the spindle turning

speed.

FLIMIT (P75)

SLIMIT (P66)

The a.m.p. "FLIMIT" sets the maximum feedrate for each axis and

the s.m.p. "SLIMIT" sets the maximum turning speed for each

spindle.

FLIMITAC (M5058)

When the PLC sets this signal high, it limits the feedrate of all the

axes. It does not let any feedrate to exceed the value set by the

corresponding a.m.p. "FLIMIT (P75)" .

SLIMITAC (M5059)

When the PLC sets this signal high, it limits the speed of all the

spindles. It does not let any feedrate to exceed the value set by the

corresponding s.m.p. "SLIMIT (P66)" .

The limitation is applied in all work modes, including the PLC

channel. When the mark is high, the CNC applies the limitation and

when going low, it restores the programmed F or S.

0 rectangular leadscrew backlash peak

1 exponential type of leadscrew backlash peak

By default 0

bit

Function

bit

Function

1

9

2

10

3

Additional pulse with G2

/ G3

11

4

12

5

13

6

14

7

15

It minimizes internal peaks

detected with the circle

geometry test

8

16

Exponential leadscrew

backlash peak

Summary of Contents for 8040 CNC - FEATURES

Page 1: ...REF 0307 SOFT M 7 XX SOFT M 7 1X 8040 CNC NEW FEATURES ...

Page 2: ...Page 2 of 2 8040 CNC NEW FEATURES SOFT M 7 XX SOFT M 7 1X ...

Page 45: ...User notes NEW FEATURES SOFT M 7 XX Page 41 of 48 8040 CNC ...

Page 46: ...User notes NEW FEATURES SOFT M 7 XX Page 42 of 48 8040 CNC ...

Page 52: ...User notes NEW FEATURES SOFT M 7 1X Page 48 of 48 8040 CNC ...

Page 53: ...Operating Manual MC option Ref 0204 ing ...

Page 143: ...Self teaching Manual MC option Ref 0112 ing ...

Page 147: ...Chapter 1 Theory on CNC machines ...

Page 156: ...Chapter 2 Theory on tools ...

Page 164: ...Chapter 3 Hands on training ...

Page 186: ...Chapter 4 Automatic Operations ...

Page 201: ...Chapter 5 Summary of work cycles ...

Page 220: ...Chapter 6 Conversational part programs ...

Page 235: ...Appendix I Programming example ...

Page 237: ...Self teaching Manual Appendix I Page 3 MC Model Programming example Step 1 Surface milling 1 ...

Page 239: ...Self teaching Manual Appendix I Page 5 MC Model Programming example Step 3 Rectangular boss 3 ...

Page 240: ...Self teaching Manual Appendix I Page 6 MC Model Programming example Step 4 Circular pocket 4 ...