N

EW

F

EATURES

(S

OFT

M: 7.

XX

)

Page 23 of 48

80

40 CNC

Improvement in the

tool measuring

cycle PROBE1

If the maximum allowed is exceeded, it issues a "tool rejected"

message and acts as follows:

If the measuring difference does not exceed the maximum allowed

or tool life monitoring is not available:

•

It updates global arithmetic parameter P299 and the length wear

value of the tool offset selected in the tool offset table.

If the dimension of each cutting edge was requested, "N" parameter,

the measured values are assigned to global arithmetic parameters

P271 and on.

31.2 Measure or calibrate the radius of a tool.

It may be carried out either with the spindle stopped or turning the in

the programmed direction (opposite to the cutting direction)

Calibration format:

(PROBE 1, B,

I2

, F, J0, K, E, S, N,

X, U, Y, V, Z, W

)

Format for wear measurement:

(PROBE 1, B,

I2

, F, J1, K, E, S, M, C, N,

X, U, Y, V, Z, W

)

Parameters J, E, S, M, C, N are optional. If not programmed, the

following values are assumed:

C0

It interrupts the execution for the user to select another tool.

C1

The cycle replaces the tool with another one of the same

family.

It sets the "rejected tool " indicator (status = R)

It activates the general logic output PRTREJEC (M5564)

P299 = measured length - theoretical length (L)

L

= theoretical length (it maintains the previous value).

K

= measured length - theoretical length (L) [New wear value]

B

Safety distance, with positive value greater than "0".

I2

Measure or calibrate the radius of a tool.

F

Probing feedrate, in mm/min. or in inches/min.

J

J0 = Calibration; J1 = Measurement

K

Probe side used.

K0 (X+ side), K1 (X- side), K2 (Y+ side), K3 (Y- side).

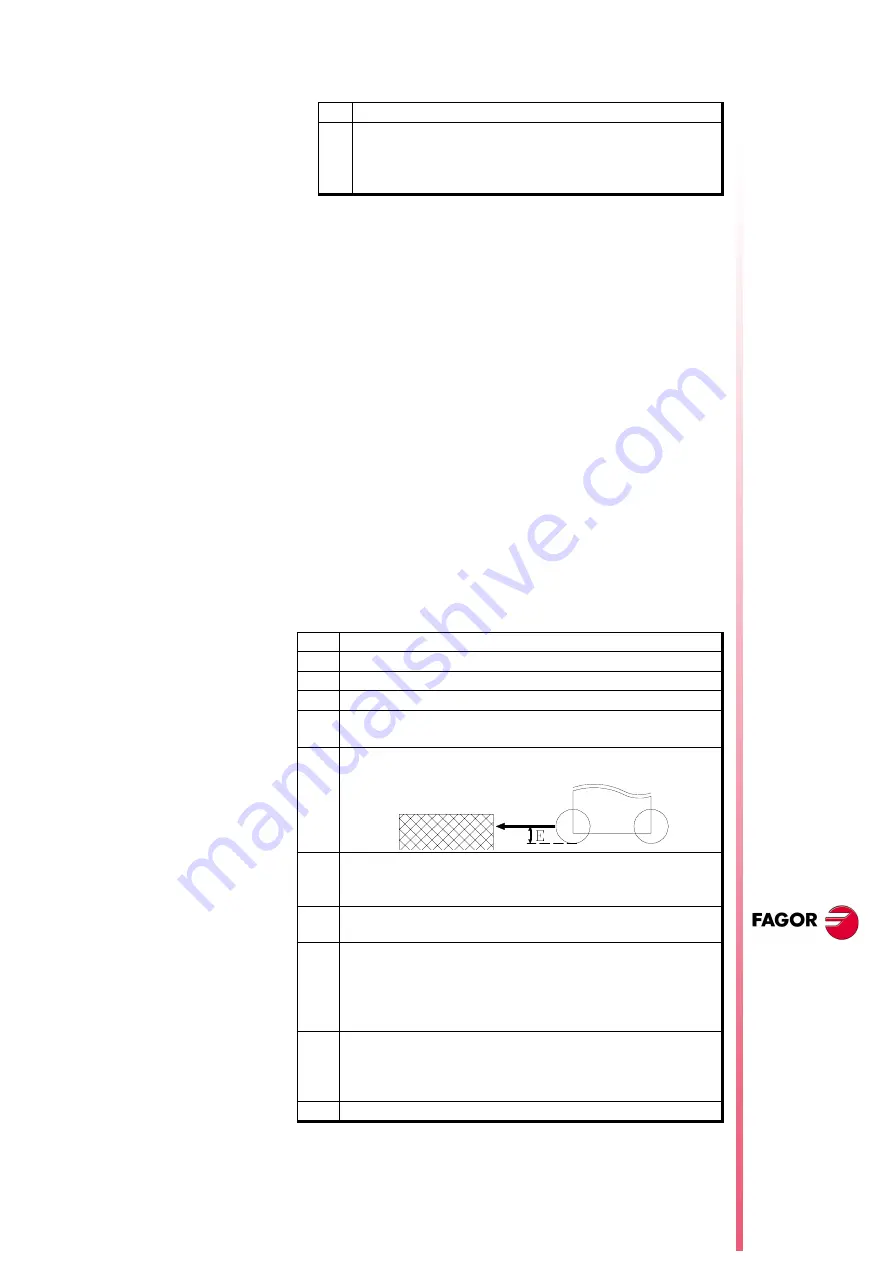

E

Distance referred to the theoretical tool tip being probed. It is

very useful with cutters whose bottom is not horizontal.

S

Tool turning speed and direction. Select the opposite of the

cutting direction (positive sign if M3 and negative if M4)

With S0, calibration with spindle stopped.

M

Maximum radius wear permitted (with J1 and when using tool

life monitoring).

C

Behavior when exceeding the maximum wear allowed (M other

than 0).

C0 = Interrupts the execution for the user to select another tool.

C1 = The cycle replaces the tool with another one of the same

family.

N

Number of cutting edges to be measured. If N0, one

measurement.

To measure each cutting edge when the spindle has feedback

and s.m.p. M19TYPE (P43) =1.

X...W Optional

Summary of Contents for 8040 CNC - FEATURES

Page 1: ...REF 0307 SOFT M 7 XX SOFT M 7 1X 8040 CNC NEW FEATURES ...

Page 2: ...Page 2 of 2 8040 CNC NEW FEATURES SOFT M 7 XX SOFT M 7 1X ...

Page 45: ...User notes NEW FEATURES SOFT M 7 XX Page 41 of 48 8040 CNC ...

Page 46: ...User notes NEW FEATURES SOFT M 7 XX Page 42 of 48 8040 CNC ...

Page 52: ...User notes NEW FEATURES SOFT M 7 1X Page 48 of 48 8040 CNC ...

Page 53: ...Operating Manual MC option Ref 0204 ing ...

Page 143: ...Self teaching Manual MC option Ref 0112 ing ...

Page 147: ...Chapter 1 Theory on CNC machines ...

Page 156: ...Chapter 2 Theory on tools ...

Page 164: ...Chapter 3 Hands on training ...

Page 186: ...Chapter 4 Automatic Operations ...

Page 201: ...Chapter 5 Summary of work cycles ...

Page 220: ...Chapter 6 Conversational part programs ...

Page 235: ...Appendix I Programming example ...

Page 237: ...Self teaching Manual Appendix I Page 3 MC Model Programming example Step 1 Surface milling 1 ...

Page 239: ...Self teaching Manual Appendix I Page 5 MC Model Programming example Step 3 Rectangular boss 3 ...

Page 240: ...Self teaching Manual Appendix I Page 6 MC Model Programming example Step 4 Circular pocket 4 ...