·200·

Programming manual

CNC 8055

CNC 8055i

9.

CANN

ED

CYCLES

·M· & ·EN· M

ODELS

S

OFT

: V02.2

X

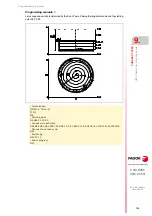

G211

. Inside

threa

d

mi

llin

g cycl

e

[ K5.5 ] Thread depth

It defines the distance between the crest and the root of the thread. If not programmed, the CNC

issues the corresponding error.

[ B±5.5 ] Thread pitch

Defines the thread pitch.

• With a positive sign, the direction of the thread pitch is from the surface of the part to the bottom.

• With a negative sign, the direction of the thread pitch is from the bottom to the surface of the part.

If not programmed or programmed with a 0 value, the CNC will display the corresponding error

message.

[ C1 ] Type of tapping

Defines the type of tapping to be carried out. This parameter depends on the type of tool being used.

• When programming C= 0, the threading will be done in a single pass.

• When programming C=1, it will make one thread per each pass (single-edge cutter).

• When programming C=n (where n is the number of cutting edges of the cutter), it will make n

threads per each pass.

If not programmed, a value of C=1 is assumed.

[ L5.5 ] Finishing stock

It defines the finishing stock at the bottom of the thread. If not programmed, a value of 0 is assumed.

[ A5.5 ] Maximum penetration step

Defines the maximum penetrating pass of the thread. If not programmed or programmed with a 0

value, it will run a single pass up to the finishing stock.

[ E5.5 ] Approach distance

Approach distance to the thread entry. If not programmed, it will enter the thread from the center

of the hole.

[ Q±5.5 ] Thread entry angle

Angle (in degrees) of the segment formed by the center of the hole and the thread entry point with

respect to the abscissa axis. If not programmed, a value of 0 is assumed.

C=0

C=1

C>1

Summary of Contents for 8055 EN

Page 1: ...CNC 8055 M EN Programming manual Ref 1711 Soft V02 2x...

Page 8: ...8 Programming manual CNC 8055 CNC 8055i SOFT V02 2X...

Page 12: ...12 CNC 8055 CNC 8055i Declaration of conformity and Warranty conditions...

Page 16: ...16 CNC 8055 CNC 8055i Version history...

Page 22: ...22 CNC 8055 CNC 8055i Returning conditions...

Page 24: ...24 CNC 8055 CNC 8055i Additional notes...

Page 26: ...26 CNC 8055 CNC 8055i Fagor documentation...

Page 448: ......

Page 464: ...464 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 466: ...466 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code MC operator panel...

Page 467: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 467 Key code...

Page 468: ...468 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 471: ...Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X 471 Key code 11 LCD Monitor...

Page 472: ...472 Programming manual CNC 8055 CNC 8055i D M EN MODELS SOFT V02 2X Key code...

Page 478: ...478 Programming manual CNC 8055 CNC 8055i F M EN MODELS SOFT V02 2X Maintenance...

Page 479: ...Programming manual CNC 8055 CNC 8055i F SOFT V02 2X 479...

Page 480: ...480 Programming manual CNC 8055 CNC 8055i F SOFT V02 2X...

Page 481: ......